Rail vehicle washing system and control method

A rail vehicle and controller technology, applied in the field of rail transit, can solve problems such as inability to work in linkage, achieve the effects of improving efficiency, improving washing effect, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

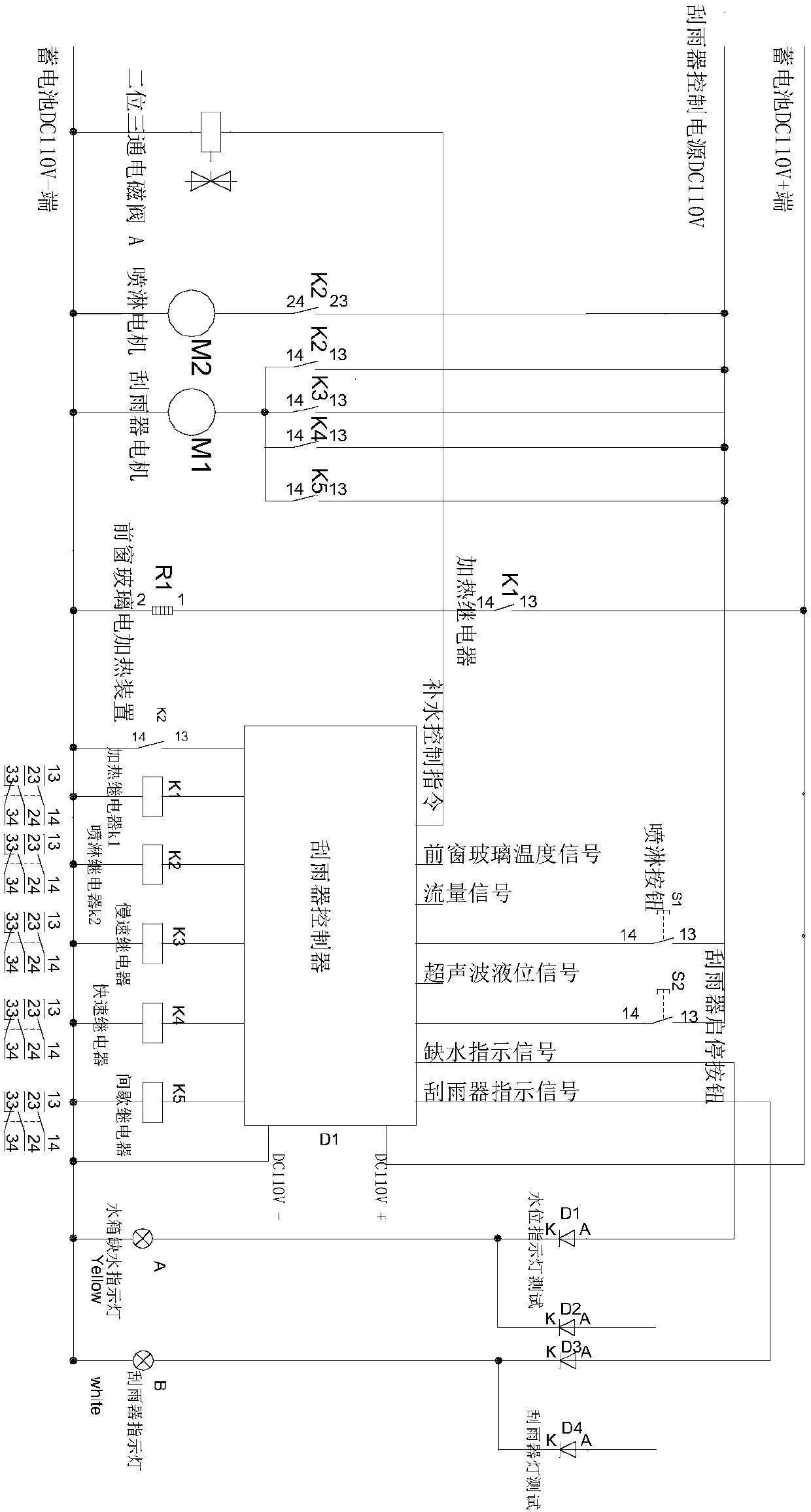

[0019] The vehicle washing system of the present invention is used for washing front window glass (including electric heating device), which includes a scraper arm, a wiper motor M1, a washing pump motor M2, a water tank, a wiper control box D1, a temperature sensor, a flow sensor, Two-position three-way valve A, liquid level sensor, heating relay K1, spray relay K2, wiper slow relay K3, wiper fast relay K4, wiper intermittent relay K5, water shortage indicator A, wiper Indicator light B, spray button S1 and wiper start and stop button S2.

[0020] Front window electric heating device: used for heating the front window and preventing the glass from freezing;

[0021] Scraper arm: used to clean the glass;

[0022] Wiper motor M1: used to drive the wiper arm;

[0023] Washing pump motor M2: used to drive the spray and spray water to the front window glass;

[0024] Water tank: used to store the spray water of the front window glass;

[0025] Wiper controller D1: used for sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com