Starch unloader for sweet potato starch production

A technology of sweet potato starch and powder bucket, which is applied in the field of sweet potato starch production auxiliary devices, which can solve the problems of low efficiency of flour production, waste of labor cost and time cost, unfavorable daily production and development of enterprises, etc., and achieves strong practicability and convenient use , saving time cost and labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

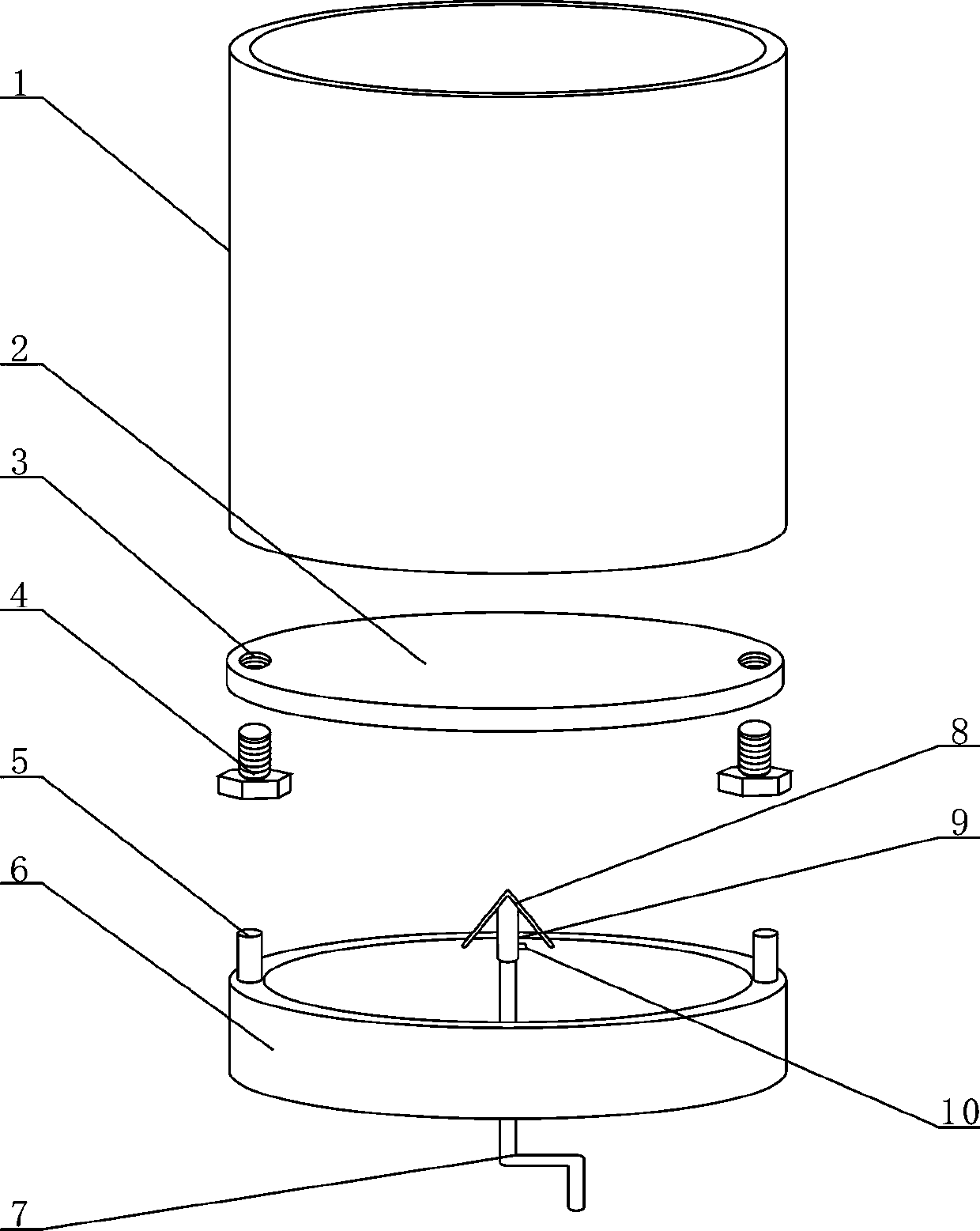

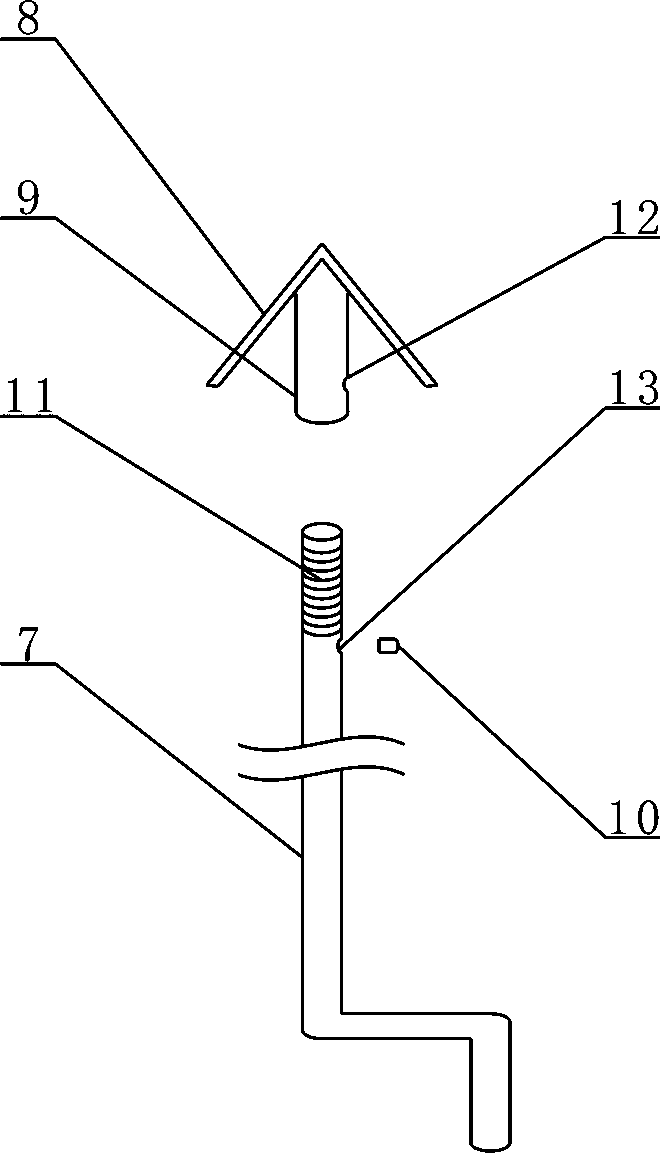

[0029] Embodiment 1, described a kind of sweet potato starch production uses the powder raising device, when in use, the both sides of containing cylinder 1 lower face are all provided with fixing grooves, then the base plate 2 is provided with fixing holes 3, and then Set the thread in the fixing hole 3, screw the bolt 4 into the fixing hole 3 and the fixing groove on the holding cylinder 1 so that the bottom plate 2 is fixedly connected with the lower surface of the holding cylinder 1, and then connect the upper part of the powder receiving bucket 6 Connecting block 5 is arranged on the surface, and then one end of crank handle 7 is set in the powder receiving bucket 6 through the lower surface of powder receiving bucket 6, and the crank handle 7 is set on the upper surface of one end of powder receiving bucket 6. Fixed block 11, screw thread is set on the fixed block 11, then the crank handle 7 is passed through the outer surface of one end of the powder receiving barrel 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com