Environment-friendly fully-synthetic cutting fluid and preparation method thereof

A cutting fluid, fully synthetic technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of easy deterioration, poor lubricity and cooling properties of cutting fluid, achieve low aerosol, solve deterioration and odor, reduce effect of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

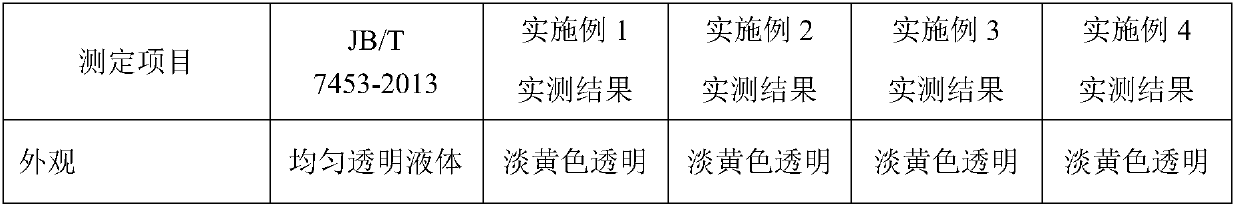

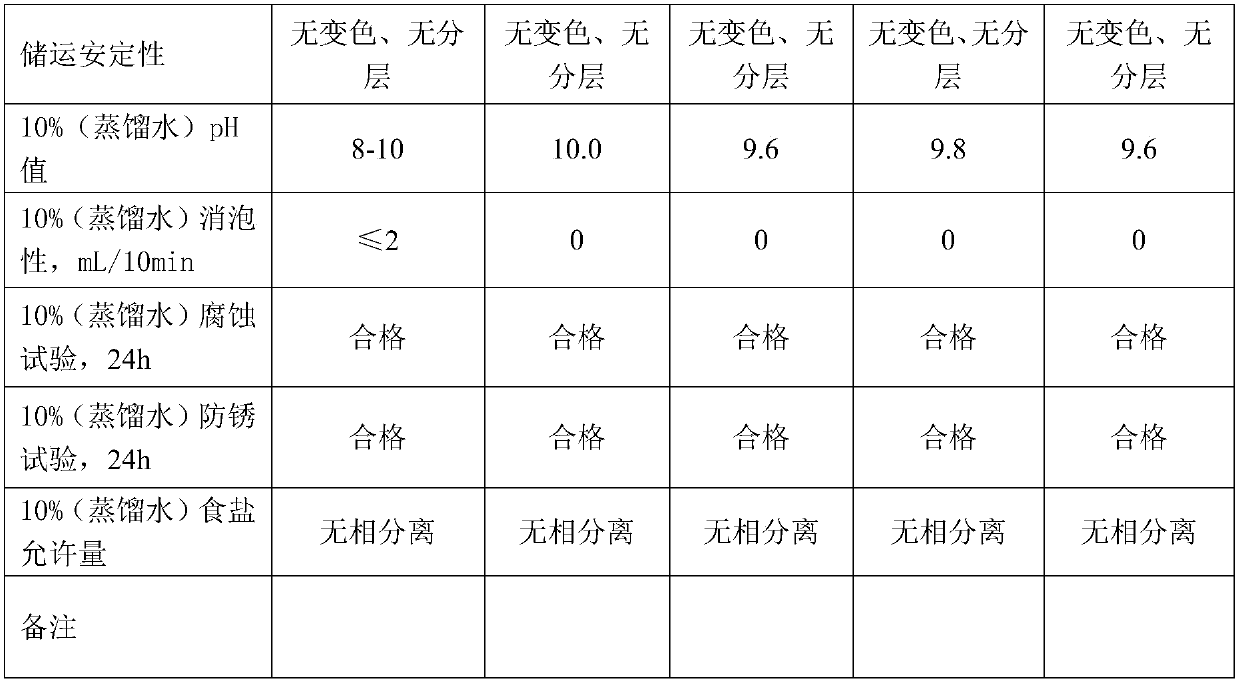

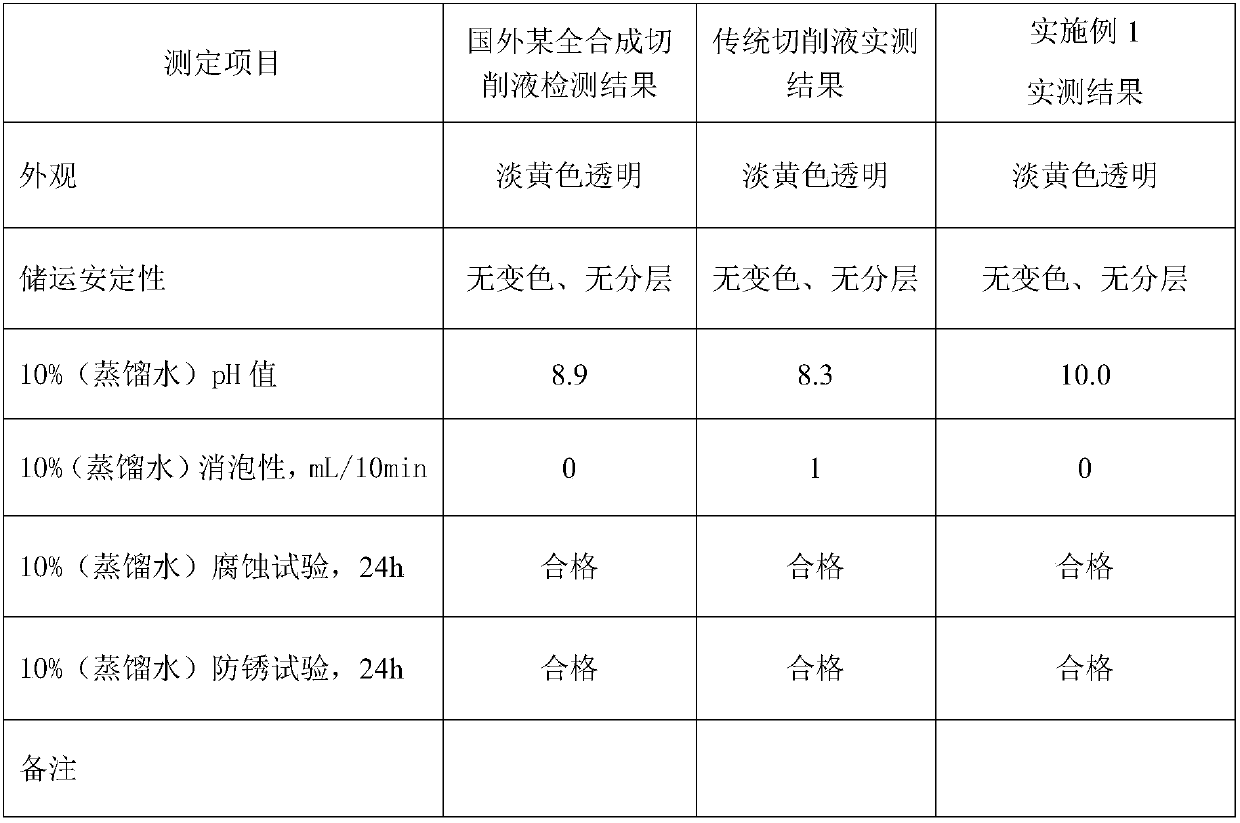

Examples

Embodiment 1

[0023] The invention provides an environment-friendly fully synthetic cutting fluid, which is composed of water, extreme pressure agent, antirust agent, pH regulator, antioxidant and defoamer, and the weight percentage of the water in the cutting fluid is 52.7%, pour water into the reactor, heat to 55°C, then add extreme pressure agent A, B, antirust agent A, B, C, pH regulator A, B, antioxidant and defoaming agent to the water Agents A and B, mixed and stirred for 50 minutes. The weight percentage of the extreme pressure agent A in the cutting fluid is 5%, the weight percentage of the extreme pressure agent B in the cutting fluid is 5%; the weight percentage of the rust inhibitor A in the cutting fluid 5%, the weight percent of the antirust agent B in the cutting fluid is 5%, the weight percent of the antirust agent C in the cutting fluid is 5%; The percentage by weight in the liquid is 10%, and the percentage by weight of the pH regulator B in the cutting fluid is 10%; the ...

Embodiment 2

[0032] The invention provides an environment-friendly fully synthetic cutting fluid, which is composed of water, extreme pressure agent, antirust agent, pH regulator, antioxidant and defoamer, and the weight percentage of the water in the cutting fluid is 60%, pour water into the reaction kettle, heat it to 60°C, then add extreme pressure agent A, antirust agent A, pH regulator A, antioxidant and defoamer A into the water, and mix and stir for 40 minutes. The percentage by weight of the extreme pressure agent A in the cutting fluid is 8%; the percentage by weight of the antirust agent A in the cutting fluid is 15%; the weight percentage of the pH regulator A in the cutting fluid The percentage is 15%, the weight percentage of the antioxidant in the cutting fluid is 0.5%, and the weight percentage of the defoamer A in the cutting fluid is 1.5%.

[0033] Further, the water is tap water.

[0034] Further, the extreme pressure agent A is refined dimer acid.

[0035] Further, the...

Embodiment 3

[0041] The invention provides an environment-friendly fully synthetic cutting fluid, which is composed of water, extreme pressure agent, antirust agent, pH regulator, antioxidant and defoamer, and the weight percentage of the water in the cutting fluid is 57%, pour water into the reaction kettle, heat to 50°C, then add extreme pressure agent A, B, antirust agent A, B, pH regulator A, antioxidant and defoamer A into the water, mix Stir for 60 minutes. The weight percentage of the extreme pressure agent A in the cutting fluid is 5%, the weight percentage of the extreme pressure agent B in the cutting fluid is 5%; the weight percentage of the rust inhibitor A in the cutting fluid 8%, the weight percent of the antirust agent B in the cutting fluid is 8%; the weight percent of the pH regulator A in the cutting fluid is 15%; The weight percentage in the cutting fluid is 0.5%, and the weight percentage of the defoamer A in the cutting fluid is 1.5%.

[0042] Further, the water is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com