Damper of composite structure

A combined structure and damper technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of non-adjustable damping and single use range of dampers, and achieve a large damping adjustment range and strong stress Uniform and reliable, broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

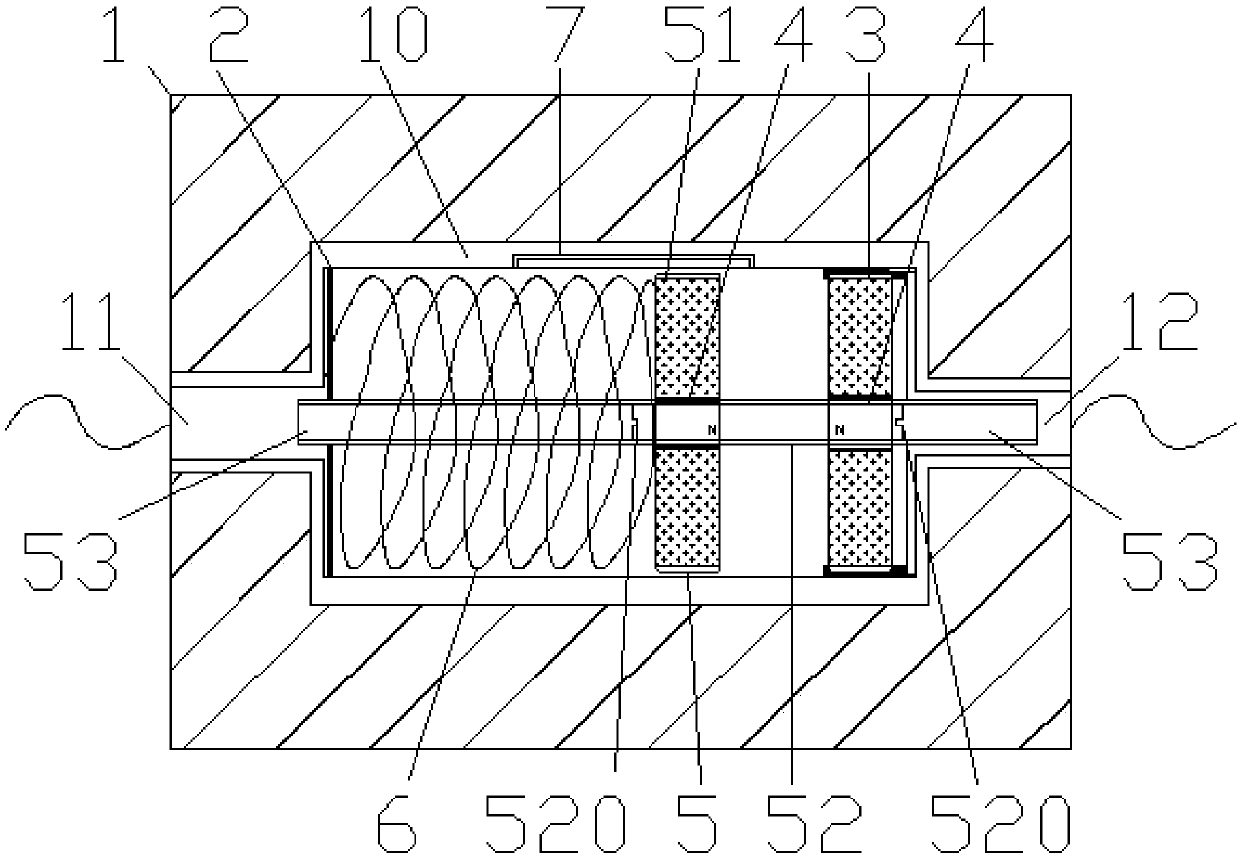

[0016] Such as figure 1 , a combined structure damper, including a housing 1 and an overall cylindrical chamber 10 inside the housing 1, the two ends of the housing 1 are provided with an oil inlet hole 11 and an oil outlet hole 12, and the damping Oil, the two ends of the inner side of the chamber 10 are fixedly connected with a fixed plate 2 having a cylindrical shape and a first magnet 3, the fixed plate 2 and the first magnet 3 both have a central hole 4, and there is a moving member 5 in the middle of the chamber 10;

[0017] The moving member 5 includes a second magnet 51 and a push rod 52, the outer diameter of the second magnet 51 is slightly smaller than the inner diameter of the chamber 10, the outer diameter of the push rod 52 is slightly smaller than the inner diameter of the first mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com