High-strength rigid-flexible flexible circuit board and manufacturing technology thereof

A flexible circuit board, a combination of soft and hard technology, used in circuit devices, circuit thermal devices, printed circuit components, etc., can solve the problems of insufficient use strength, poor heat dissipation effect, and complexity, and achieve enhanced use strength and protection effect. Good, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

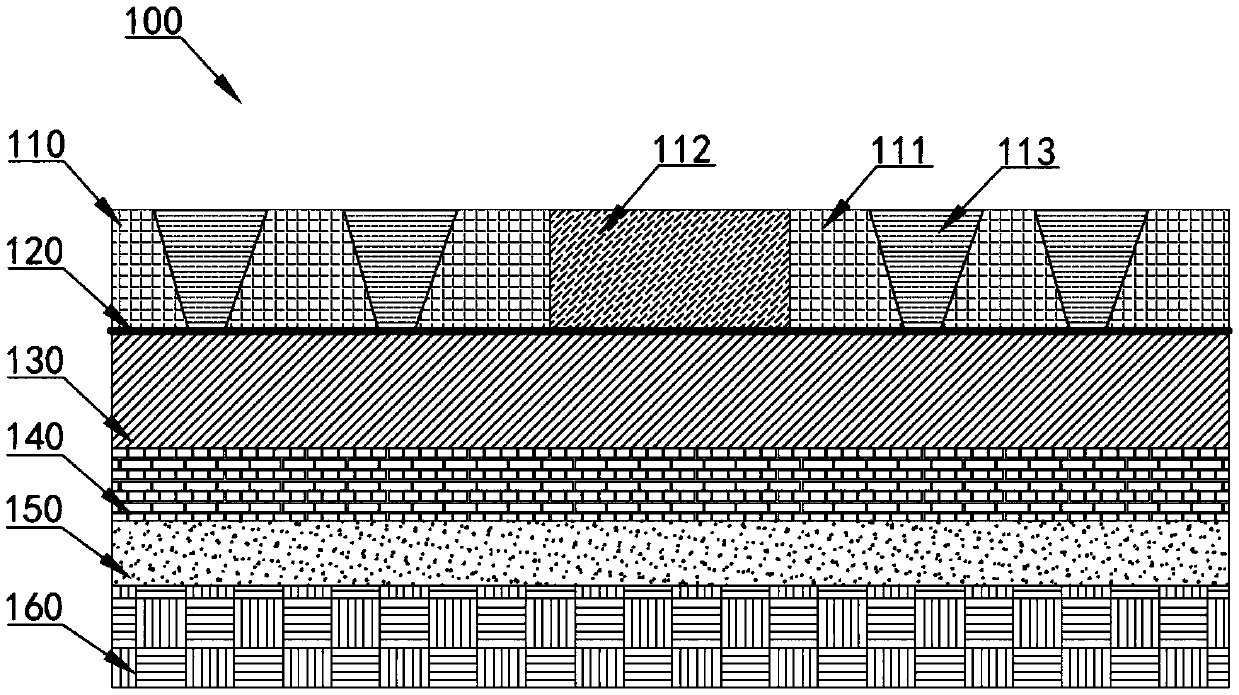

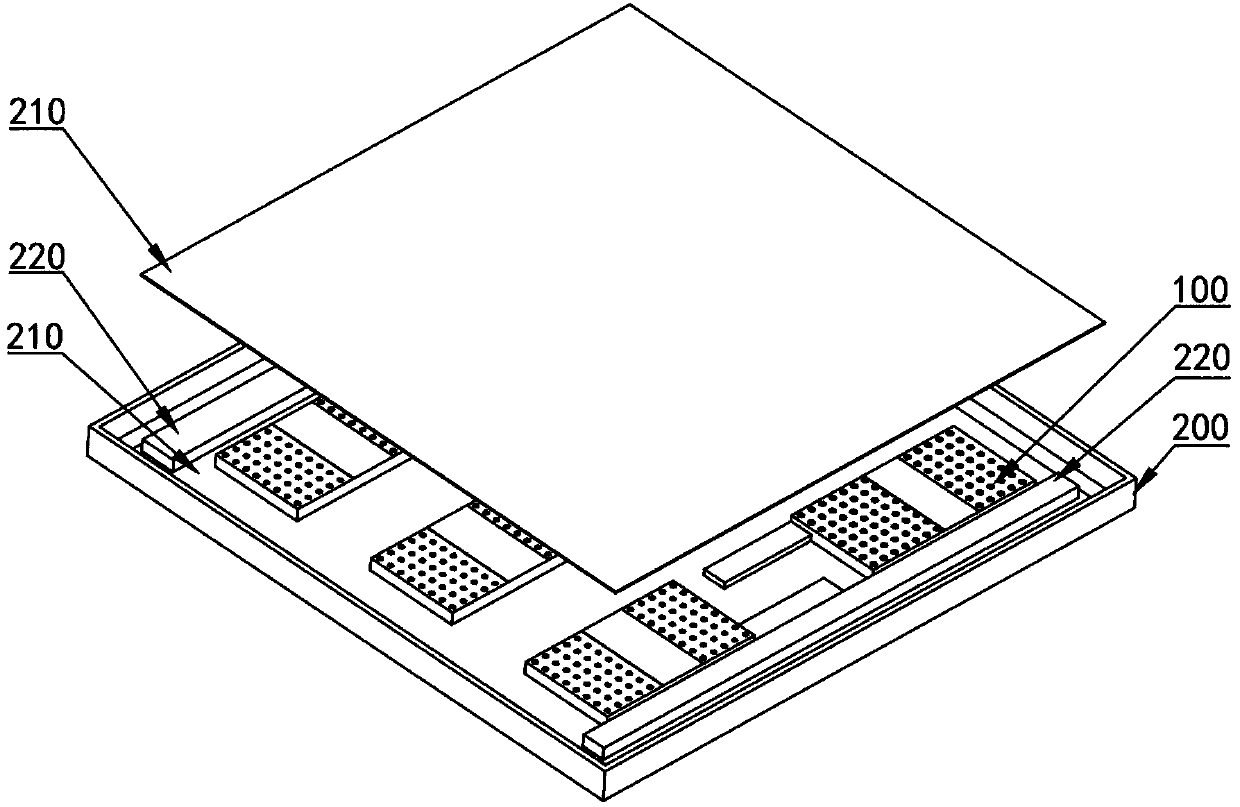

[0028] Such as figure 1 Shown is a schematic diagram of the flexible circuit board body of the present invention.

[0029] A high-strength soft-rigid flexible circuit board, including a flexible circuit board body 100, the flexible circuit board body 100 includes a reinforcement layer 110, an adhesive layer 120, a main base layer 130, and a printed circuit board arranged in sequence from top to bottom. Layer 140, anti-interference layer 150 and silica gel protective layer 160, the reinforcing layer 110 is pasted on the surface of the main base layer 130 through the adhesive layer 120, the printed circuit layer 140 is printed on the side of the main base layer away from the reinforcing layer 110, the The anti-interference layer 150 is coated on the printed circuit layer 140, and the silicone protective layer 160 is coated on the anti-interference layer 150; the reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com