Squeeze-type circulation flow reaction vessel

A circulating flow, extrusion technology, applied in chemical/physical/physical chemical fixed reactors, cleaning hollow objects, chemical/physical/physical chemical processes, etc., can solve the problem of affecting the production efficiency of chemical products, long time , slow processing speed and other problems, to achieve the effect of increasing the mixing reaction rate, ensuring the mixing of raw materials, and improving the mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

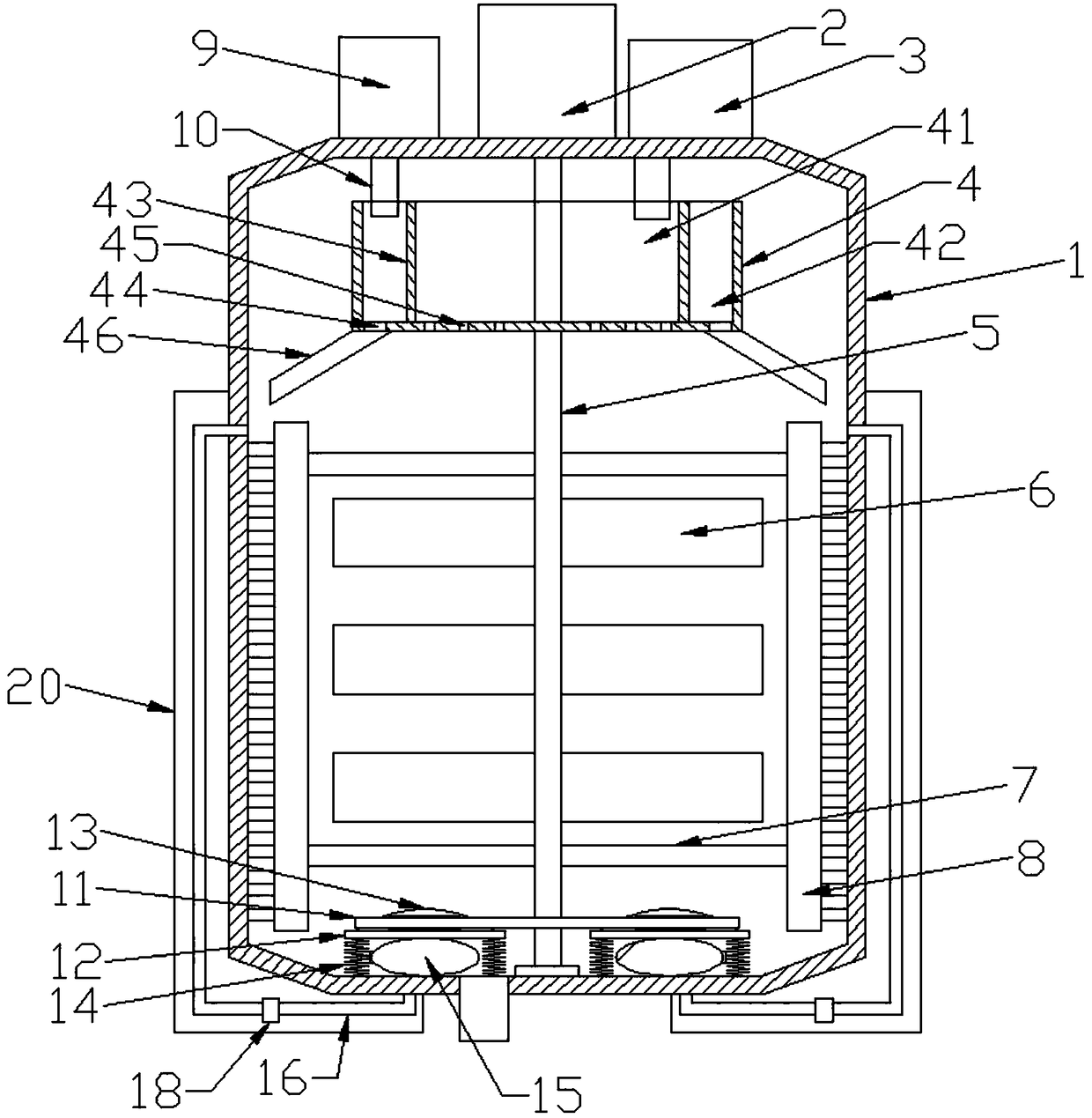

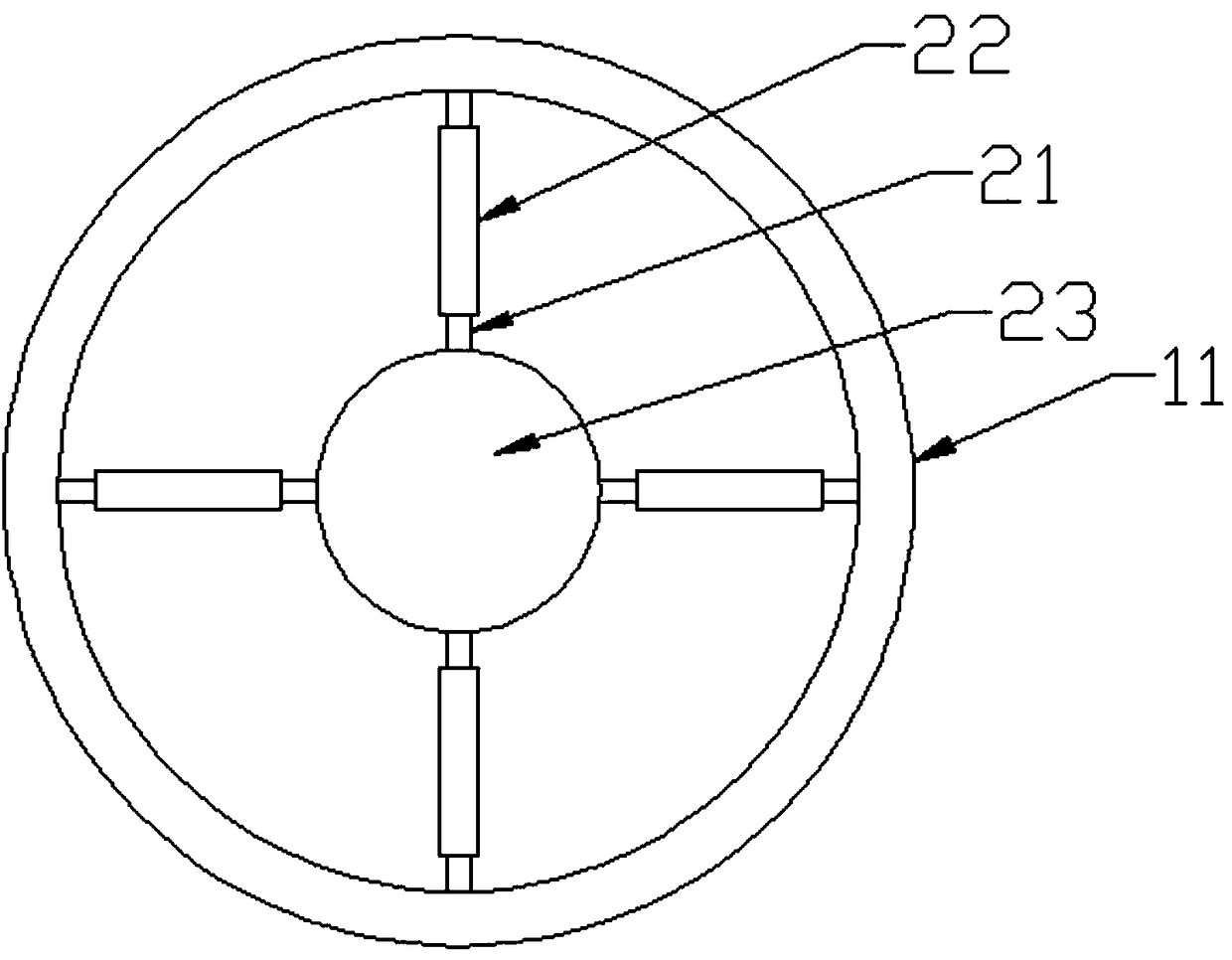

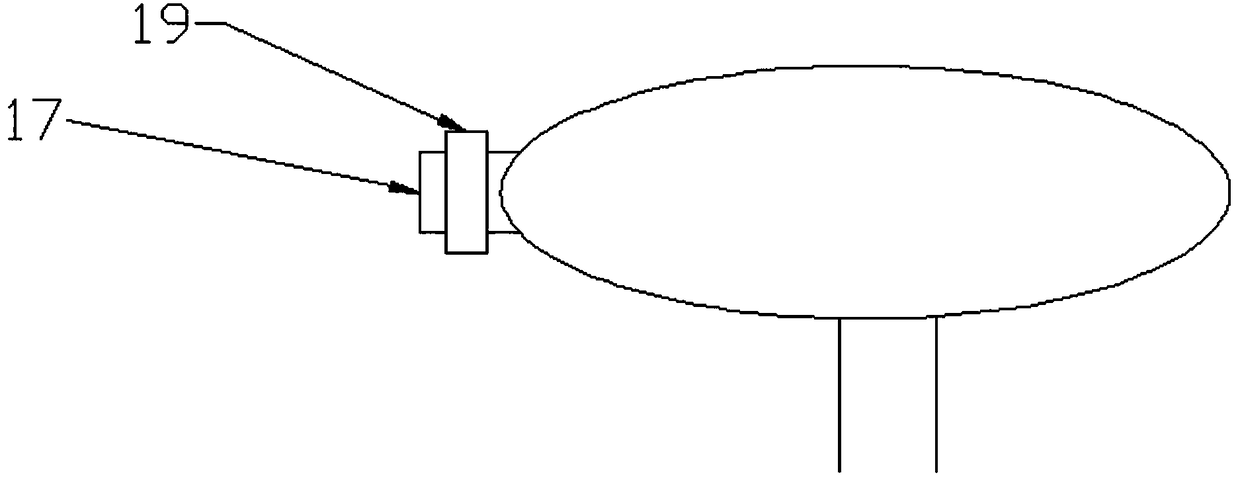

[0018] Please refer to the figure, in the embodiment of the present invention, a reaction kettle with extruding circulation flow includes a kettle body 1, a motor 2, a feed hopper 3, a stirring shaft 5 and a stirring blade 6; the motor 2 is fixedly installed in the kettle On the top of the body 1, the output shaft of the motor 2 extends vertically downward into the kettle body 1, and a vertical stirring shaft 5 is fixedly connected to the lower end of the output shaft of the motor 2, and the lower end of the stirring shaft 5 is connected to the kettle body through bearing rotation. At the bottom of the body 1, several stirring blades 6 are fixed on the stirring shaft 5, and the motor 2 drives the stirring shaft 5 to rotate, so that the stirring blades 6 can stir the inside of the kettle body 1; a horizontal rotating box is fixed on the stirring shaft 5 4. The central axis of the rotating box 4 coincides with the stirring shaft 5, and the rotating box 4 follows the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com