Bobbin thread winder of sewing machine and sewing machine

A technology of a winding device and a sewing machine, which is applied in the direction of bobbin winding in the sewing machine, sewing machine components, sewing equipment, etc., can solve the problem of not being able to accurately grasp the winding amount of the lower thread of the bobbin, and achieve the effect of reducing the workload of the work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] [Outline of Embodiments of the Invention]

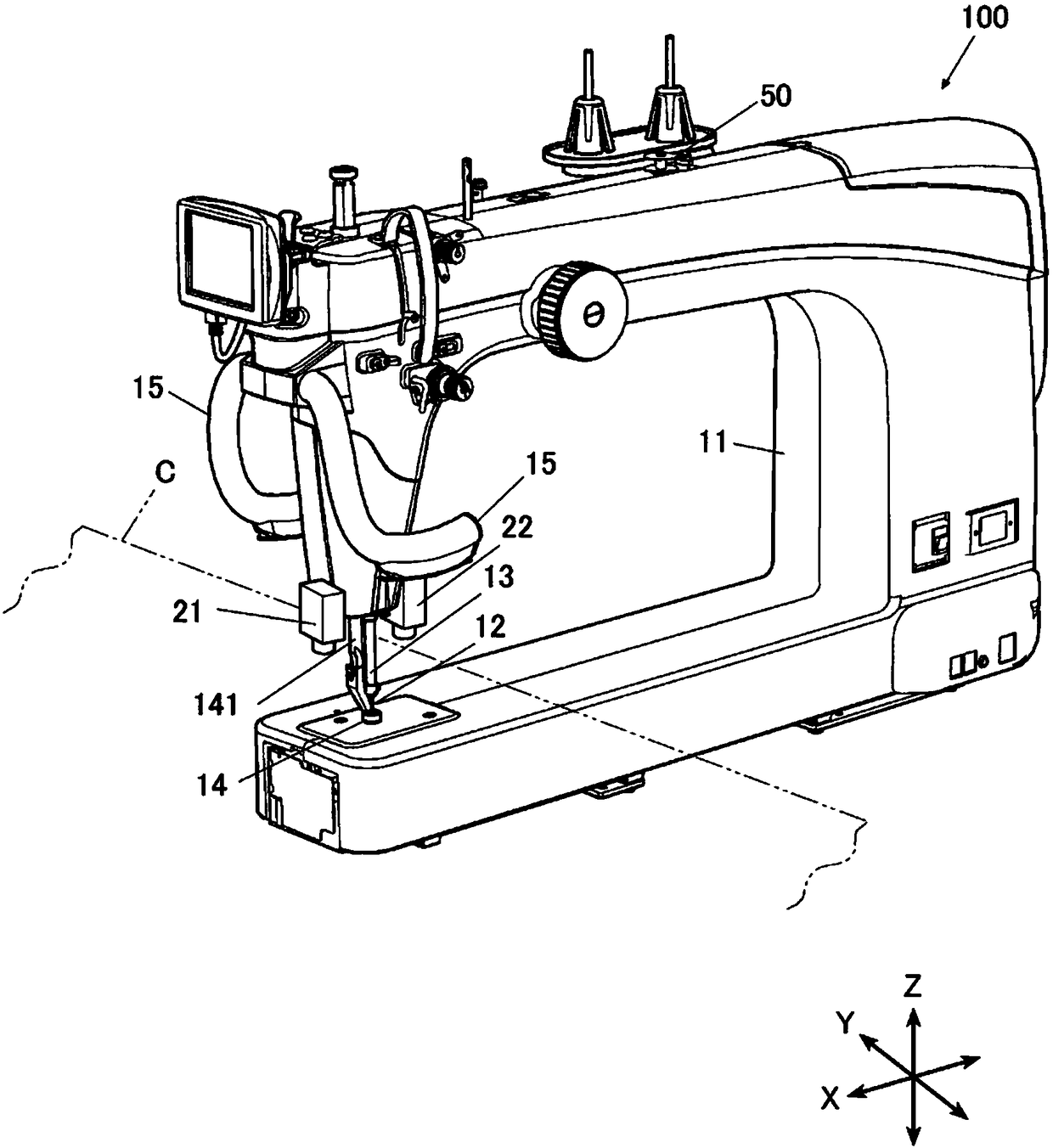

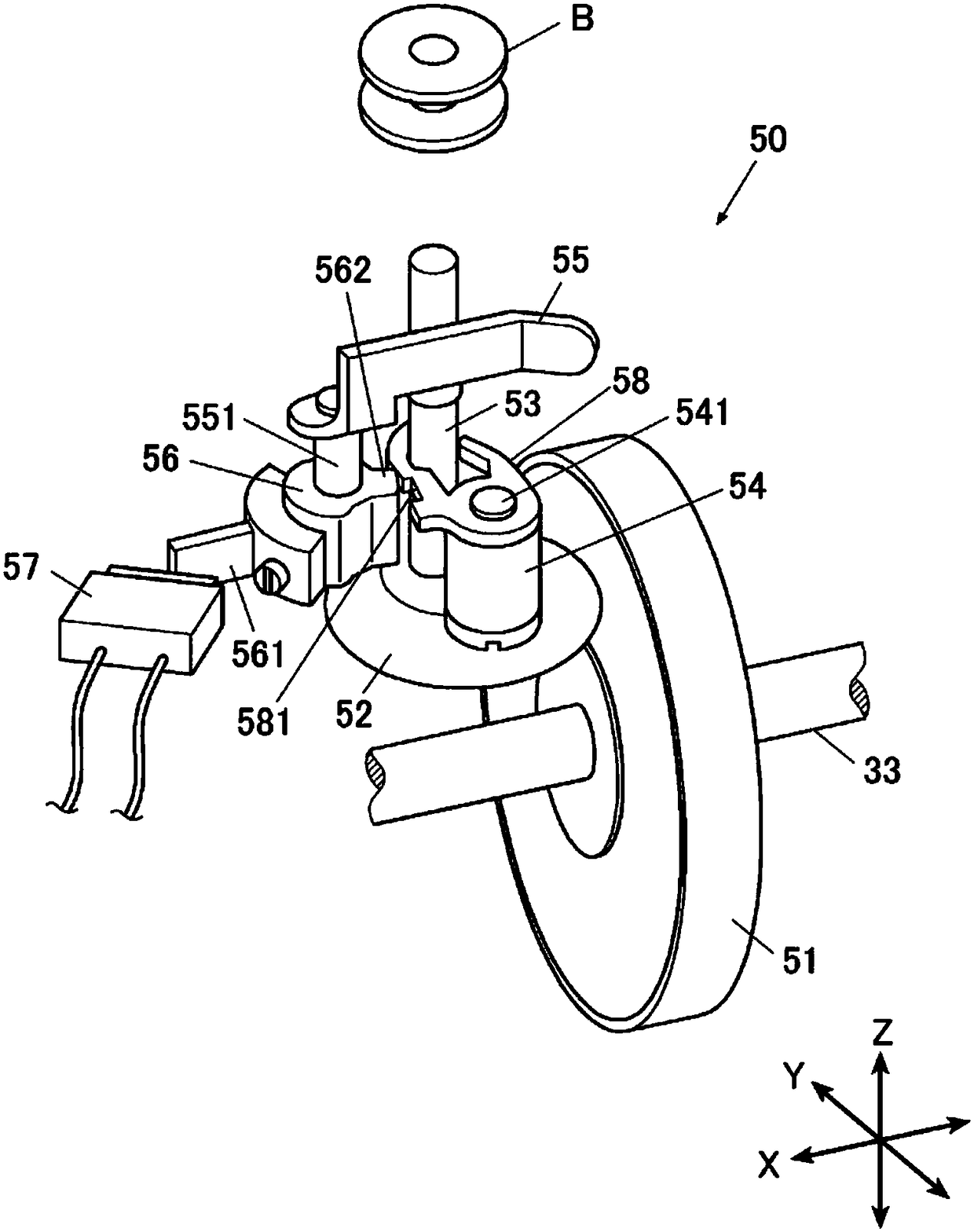

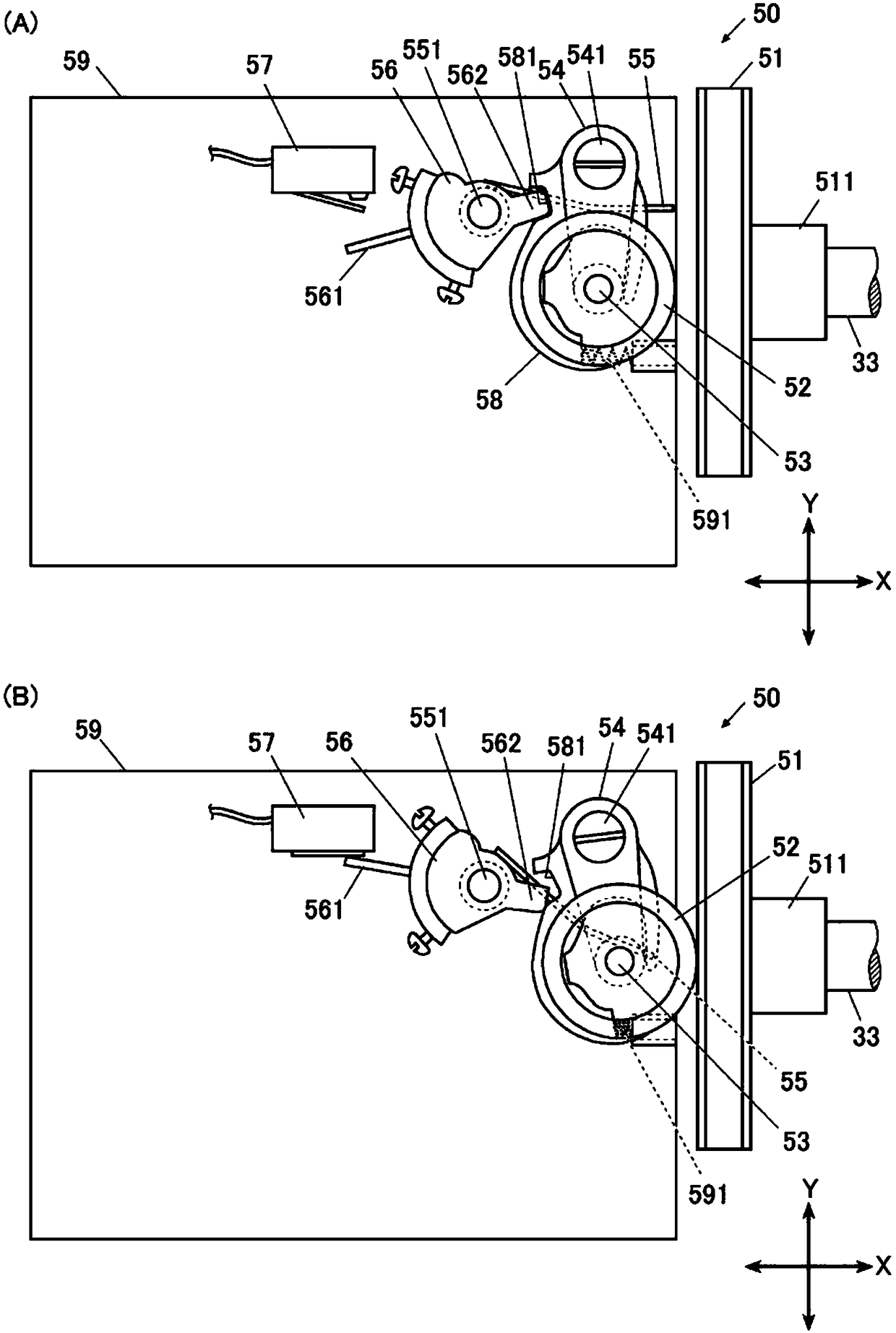

[0055] Next, a sewing machine according to the present invention will be described with reference to the drawings. figure 1 is a perspective view of the sewing machine 100.

[0056] In addition, the sewing machine 100 of this embodiment is capable of so-called free movement sewing, that is, the sewing machine 100 can be freely moved along a horizontal plane by a holding table that holds the clothing material of the sewing object in a horizontally stretched state. The sewing operator sews the clothing while moving the sewing machine 100 arbitrarily.

[0057] In addition, in this embodiment, illustration of a holding stand and description of a structure are the same as a well-known holding stand, and are abbreviate|omitted.

[0058] The sewing machine 100 has: a needle bar vertical movement mechanism that moves the needle bar 13 holding the sewing needle 12 at the lower end up and down; a kettle mechanism that catches the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com