a washing machine

A washing machine and cabinet technology, applied in the field of washing machines, can solve the problems of not being able to save labor costs, etc., and achieve the effects of convenient installation, improved maintenance efficiency, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

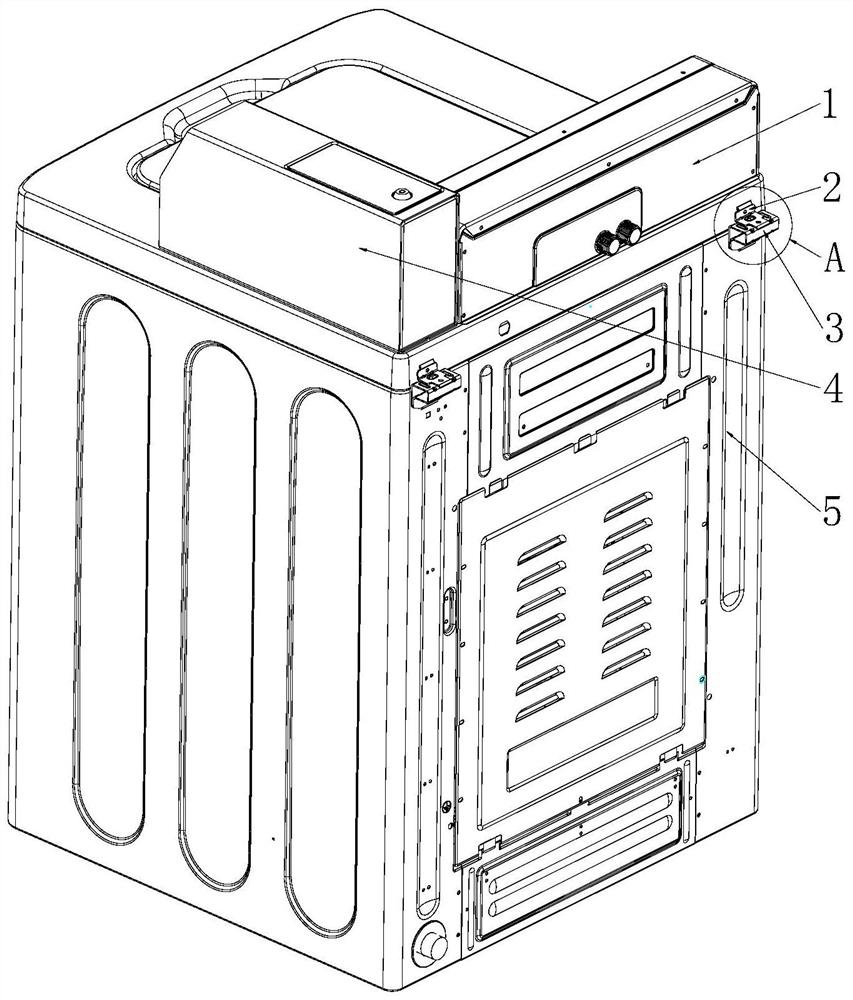

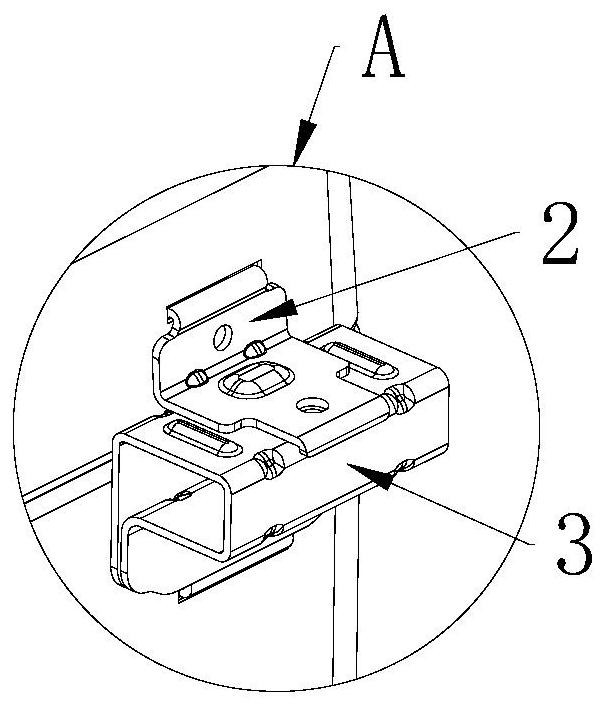

[0043] Such as Figure 1 to Figure 11 As shown, in the washing machine described in this embodiment, the conversion connecting device includes a first part 2 and a second part 3, the second part 3 is provided with a clamping part and a hinge part, the first part 2 is provided with a connecting part, and the connecting part is connected The switchable connection between the part and the clamping part and the hinge part. The box body 5 is provided with a clamping part, and the disk base 1 is provided with a fixing part 11 matched with the clamping part. The box body 5 is provided with a positioning unit 7 , and the disc base 1 is provided with a slide groove 10 cooperating with the positioning unit 7 .

[0044] Specifically, the rear side of the disk base 1 is connected with the first part 2, and the first part 2 is fixedly installed on the disk base 1 through clamping and screw connection, and the rear side plate of the box body 5 is connected with the second part 3, and the s...

Embodiment 2

[0051] Such as Figure 1 to Figure 11 As shown, in the washing machine described in this embodiment, the positioning unit 7 includes a mounting part 12, a guiding part 13 and a positioning part 14, the positioning unit 7 is connected to the box body 5 through the mounting part 12, and the guiding part 13 is used to guide the chute 10 is fitted in the positioning part 14, and the disk base 1 is slidably connected with the box body 5 through the cooperation of the sliding groove 10 and the positioning part 14. The chute 10 is provided with a profiling, and when the chute 10 slides until the profiling matches with the positioning unit 7 , the profiling part 9 cooperates with the guide part 13 .

[0052] Specifically, the mounting part 12 is a countersunk through hole that runs through the positioning unit 7. The positioning unit 7 is screwed through the mounting part 12 and the box body 5 through the screw. The chute 10 is cooperatingly installed on the positioning portion 14 , ...

Embodiment 3

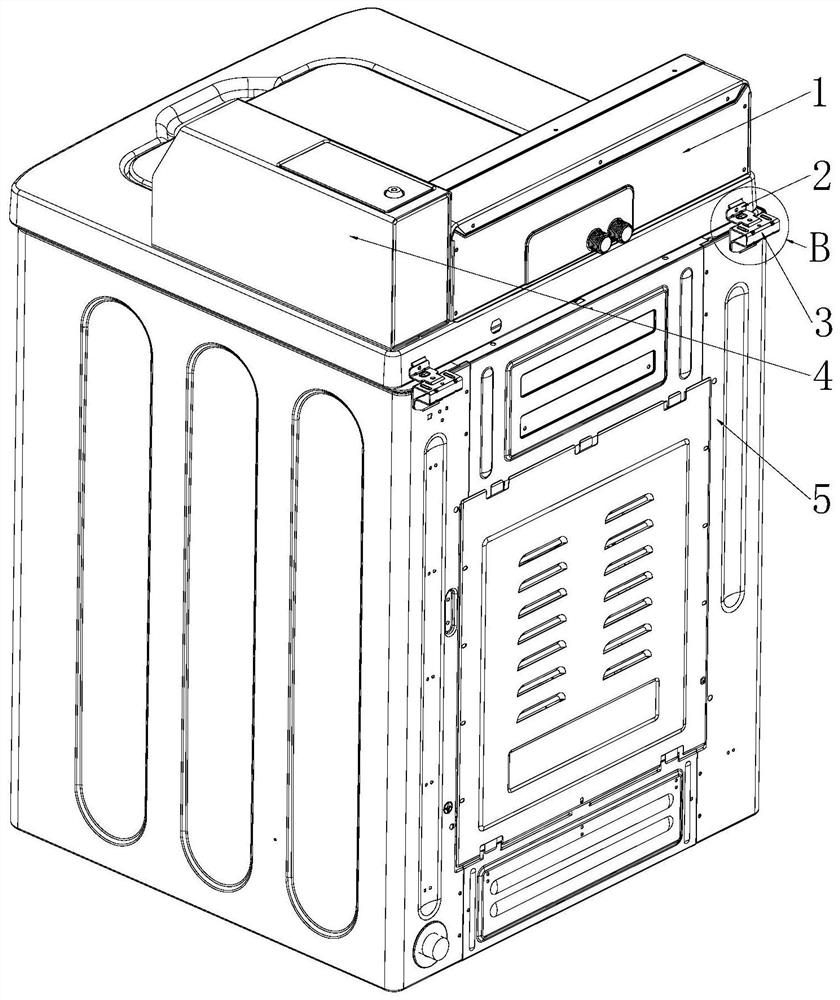

[0055] Such as Figure 1 to Figure 11 As shown, the washing machine described in this embodiment further includes a locking unit 8 for relatively fixing the locking disc base 1 and the box body 5 . It also includes a coin box 4 , one end of the locking unit 8 is connected to the box body 5 , and the other end is detachably connected to the disk base 1 , and the position connected to the disk base 1 is located in the coin box 4 .

[0056] Specifically, the washing machine also includes a coin box 4, the coin box 4 is arranged on the disk base 1, the corner of the box body 5 is provided with a corner plate, and one end of the locking unit 8 is connected to the corner plate screw by a screw, and the locking unit 8 The other end is screwed to the disk base 1 through screws, and the position connected to the disk base 1 is located in the coin box 4 . When the disk base 1 needs to be disassembled, the cover plate of the coin box 4 must be opened first, and after the locking unit 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com