Flow adjustable fluid injection device

A fluid injection and adjustable technology, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of difficult control of fluid flow and fluid speed, reduce the possibility of leakage, prolong service life, Reduce the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

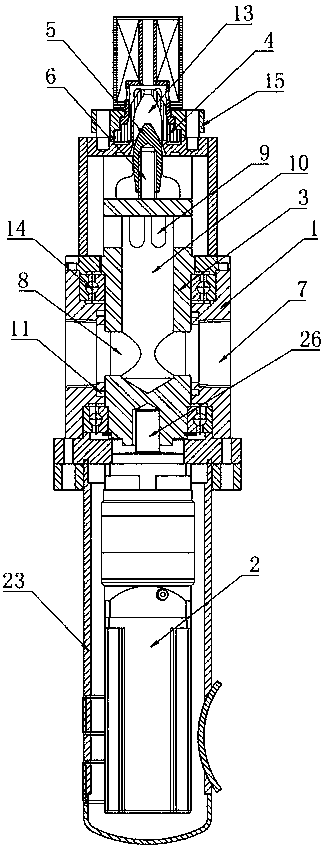

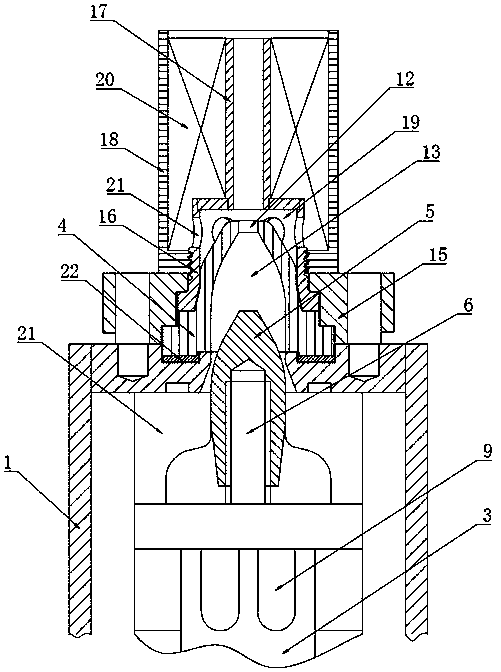

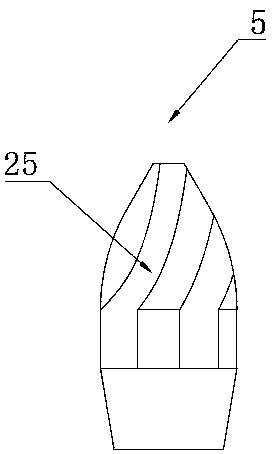

[0035] Example: such as Figure 1 to Figure 3 As shown, a flow-adjustable fluid injection device includes a sleeve 1, a rotary drive mechanism 2, a rotating main shaft 3, a spray head 4 and a piston rod 5, the rotating main shaft 3 is arranged inside the sleeve 1, and the spray head 4 is connected with the head end of the sleeve 1, and the rotary drive mechanism 2 is arranged at the tail of the sleeve 1 and connected with the tail of the rotating main shaft 3, and the head end of the rotating main shaft 3 is provided with a travel wire rail 6, and the piston The tail of the column 5 is provided with a threaded hole, and the travel wire rail 6 is passed through the threaded hole of the piston column 5 and is threadedly connected with the piston column 5, and the piston column 5 is slidably connected with the sleeve 1, and the sleeve 1 The side wall of the side wall is provided with a side wall water inlet 7, the middle part of the rotating main shaft 3 is provided with a main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com