Non-metal lamp arm and production method thereof and lamp with lamp arm

A non-metallic lamp arm technology, applied in lighting and heating equipment, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of simple shape, poor decoration, heavy weight of die-casting metal lamp arm, and difficulty in threading wires And other problems, to achieve the effect of low production process cost, light weight, complex and changeable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

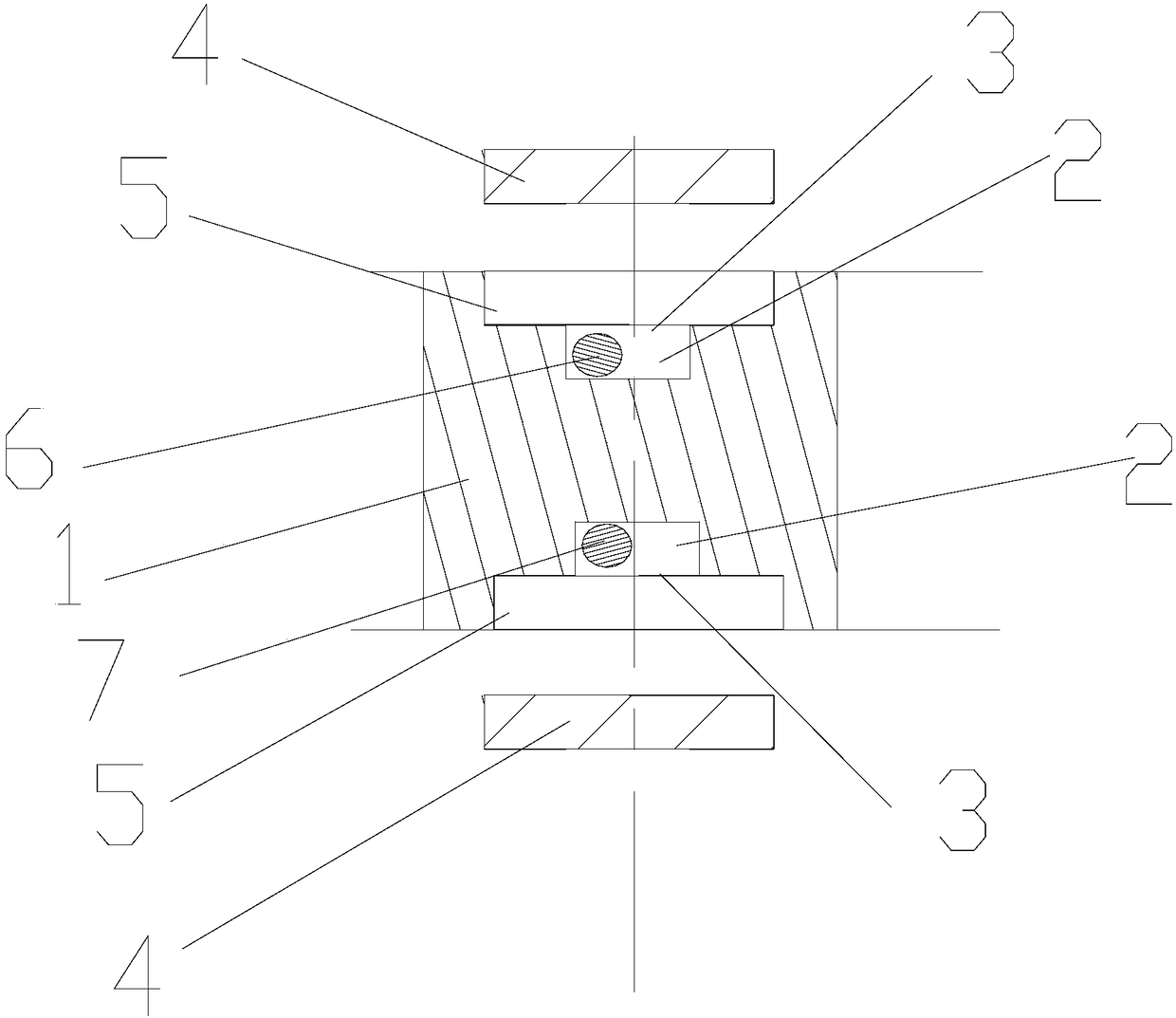

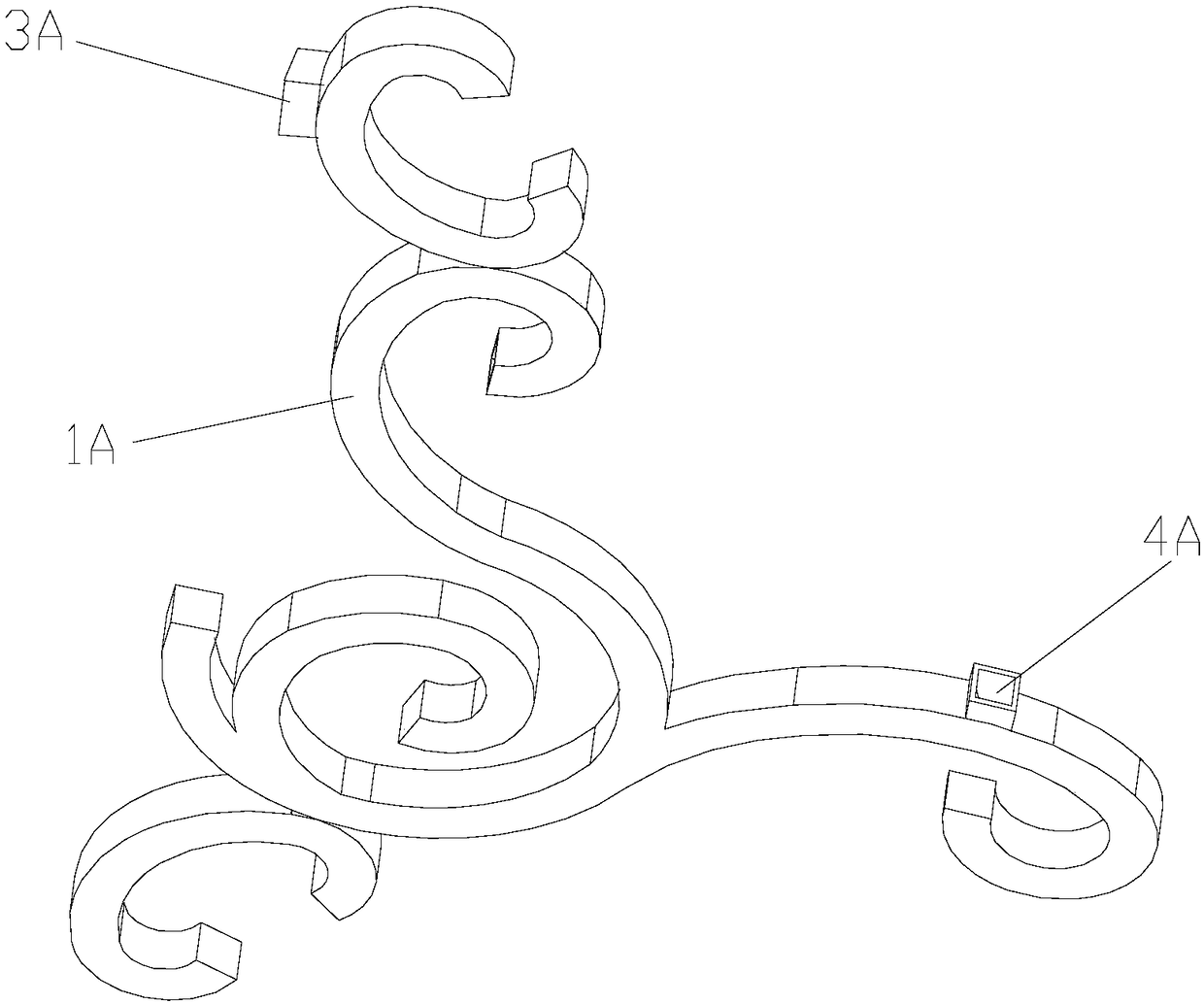

[0049] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a non-metallic lamp arm of the present invention includes a lamp arm body 1 made of bamboo or wood, spray paint and flocking on the outer surface of the lamp arm body 1 to cover the surface of the bamboo or wood raw material, and is characterized in that: The surface of the side wall of the arm body 1 is recessed with a wire groove 2, and the top of the wire groove 2 is provided with an opening 3 where the power supply line is embedded in the wire groove 2, and a decorative plate 4 is laid above the opening 3 to cover the wire groove 2, and the decorative plate 4 Attached to the lamp arm body 1 , the width of the decorative plate 4 is greater than the width of the opening 3 . The lamp arm body 1 is electrically insulated and opaque. A wire groove 2 is dug out on the surface of the side wall of the lamp arm body 1, the positive wire 6 and the negative wire 7 are laid...

Embodiment 2

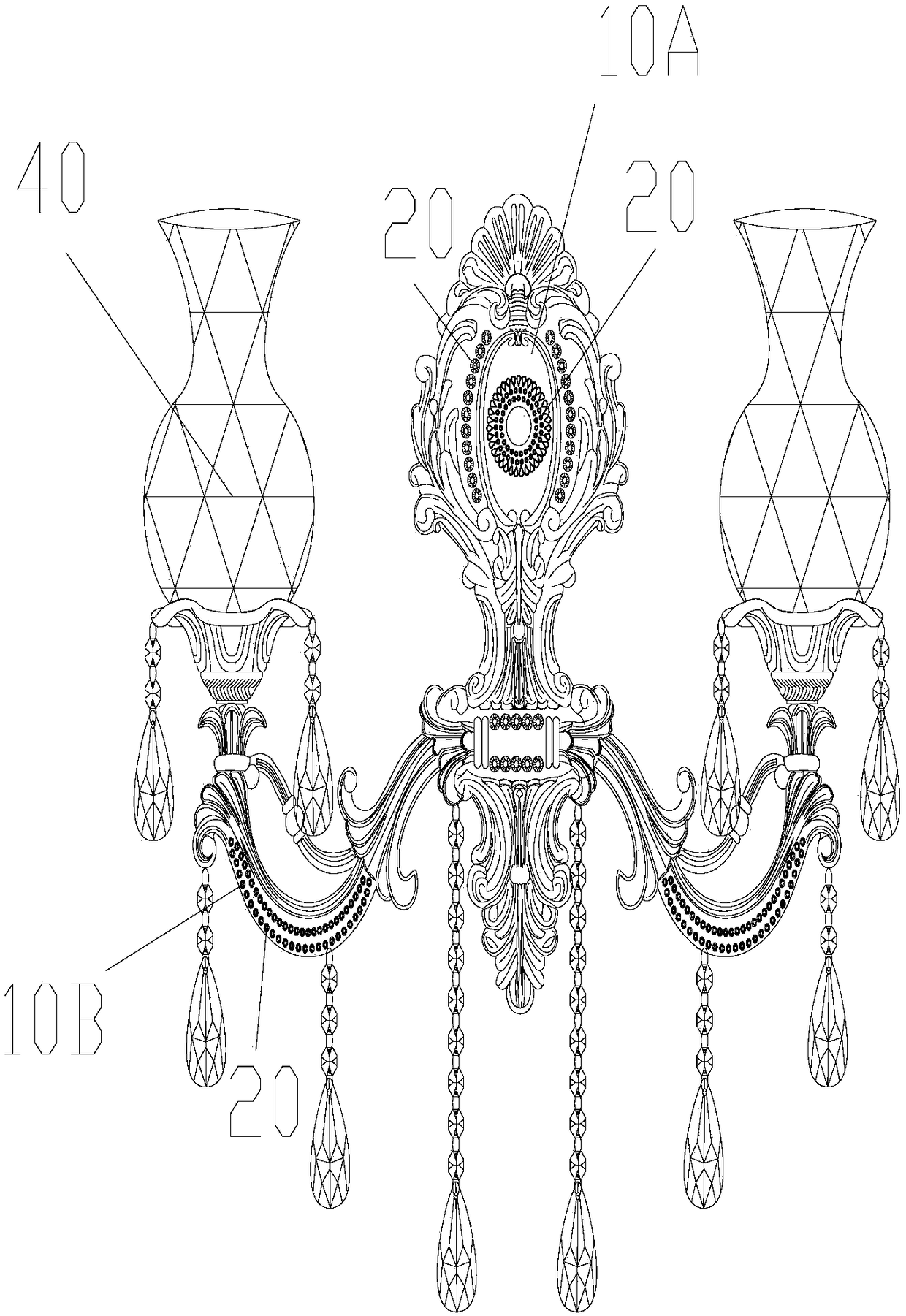

[0058] It includes a lamp drum, a lamp arm, a lamp holder and an LED light source installed on the lamp holder. The lamp arm is the lamp arm described in Embodiment 1, the wires are laid in the wire groove 2, and screws are installed at both ends of the lamp arm body 1 The metal parts are respectively connected with the lamp drum and the lamp holder. Two wire slots 2 are respectively recessed on the surfaces of two different side walls of the lamp arm body 1 , and these two wire slots 2 provide wire passages for the positive wire 6 and the negative wire 7 respectively. Lamp holders are installed at outlet 9 and inlet 8, and LED light sources installed on the lamp holders

Embodiment 3

[0060] A method for producing a non-metallic lamp arm. First, according to the shape of the lamp arm, the lamp arm body 1 is made of bamboo or wood non-metallic insulating material, and then a wire groove 2 is dug out on the surface of the side wall of the lamp arm body 1. The positive wire 6 and the negative wire 7 are laid in the wire groove 2 through the opening 3, and finally the decorative plate 4 is laid on the lamp arm body 1 to cover the wire groove 2.

[0061] It can be laid on the surface of the lamp arm body with any complex shape. The process is simple and fast. The wires are laid in parallel on the front and back of the lamp arm body. They are completely isolated from each other and there is no risk of damage or short circuit. , The wiring distance is short, saving raw materials and reducing costs.

[0062] Generally, bamboo or wood is cut through CNC engraving to obtain complex shapes or simple shapes of the lamp arm body 1. At the same time, the wire groove 2 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap