Magnesium oxide board thickness and roughness online measurement device and using method

A measuring device and glass magnesium plate technology, applied in measuring devices, instruments and other directions, can solve the problems of large size, loss, and error of glass magnesium plate, and achieve the effects of easy adjustment and improvement, improvement of production efficiency, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

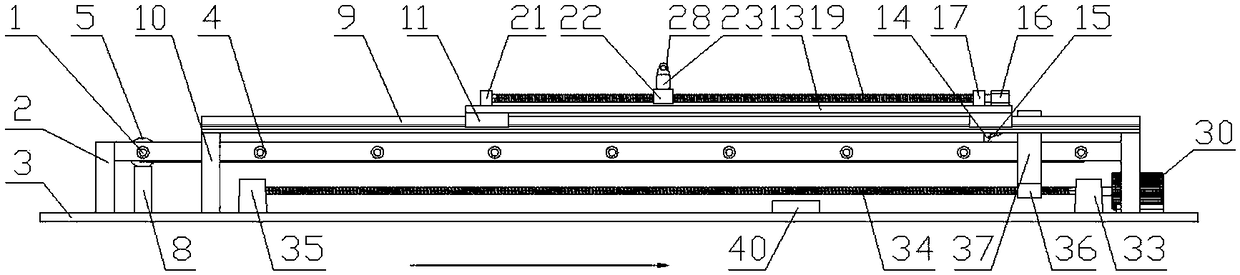

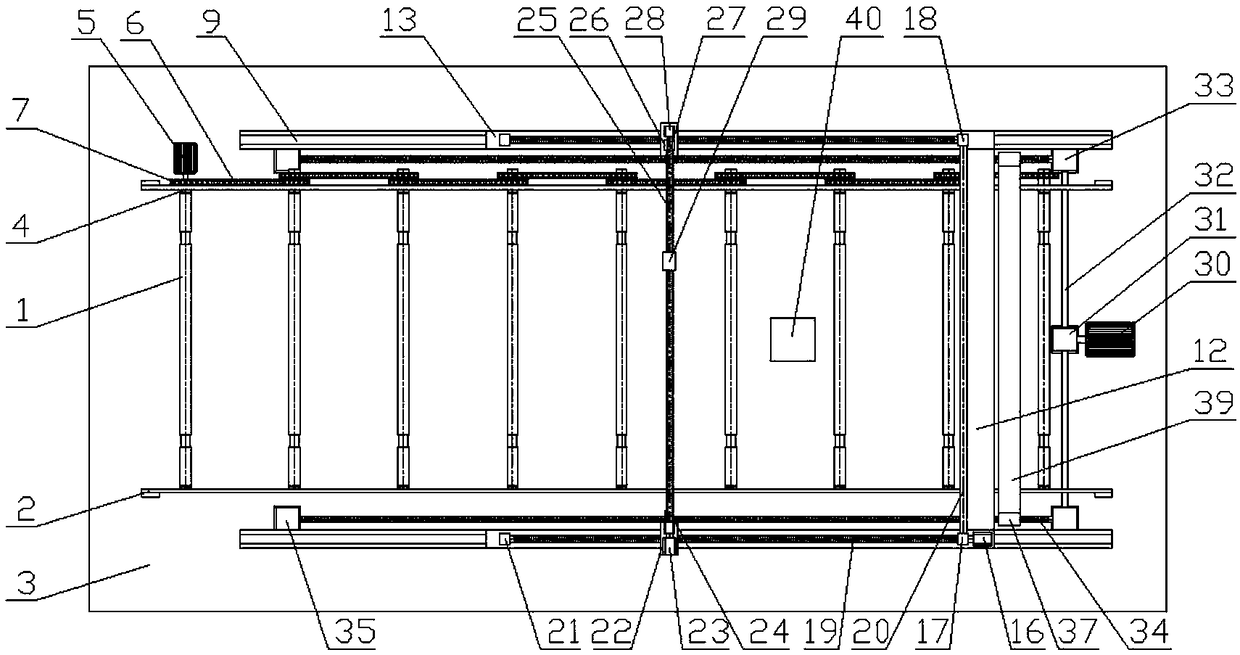

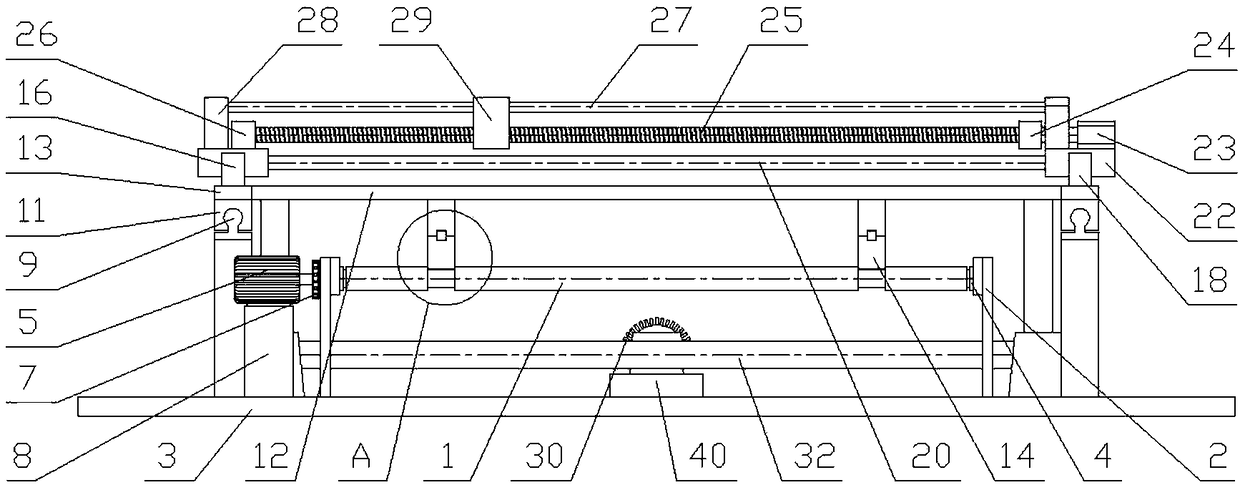

[0044] Such as Figures 1 to 3 An on-line measurement device for the thickness and unevenness of a glass magnesium board is shown, including a board conveying component, a follower component that can move with the glass magnesium board, a measuring component for measuring the distance between the upper surface of the glass magnesium board and the distance sensor, and the The above-mentioned follow-up component returns to the reset component to the initial position, and the scanning component scans and recognizes the barcode of the plate.

[0045] Such as Figures 4 to 5 As shown, the plate conveying assembly includes a roller 1, a bracket 2, a bottom plate 3, a rolling bearing with a seat 4, a conveying motor 5, a chain 6, a sprocket 7 and a conveying motor bracket 8, and the roller 1 is provided with grooves in the circumferential direction. The support 2 includes a pair of parallel beams and longitudinal beams connecting the beams and the bottom plate 3, a plurality of roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com