Method for extracting lithium from slag produced by fire recovery lithium battery

A technology for recovering and extracting lithium, applied in the field of lithium extraction, can solve the problems of high removal cost of aluminum ions, no recovery of lithium resources, and complex slag composition, so as to improve the comprehensive utilization value, save calcium removal reagents, and reduce alkali reagents. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

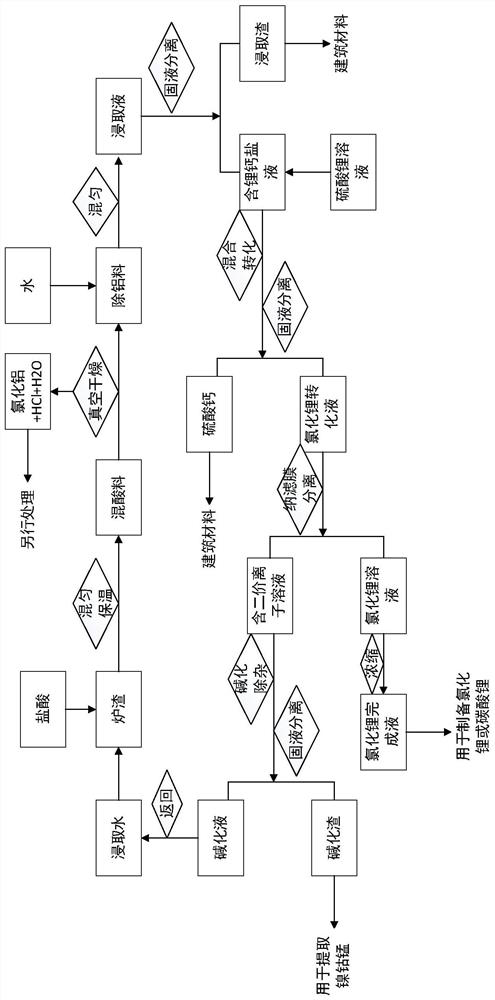

Method used

Image

Examples

Embodiment 1

[0073] Follow the steps below to extract lithium from the slag produced by pyro-recycling lithium batteries:

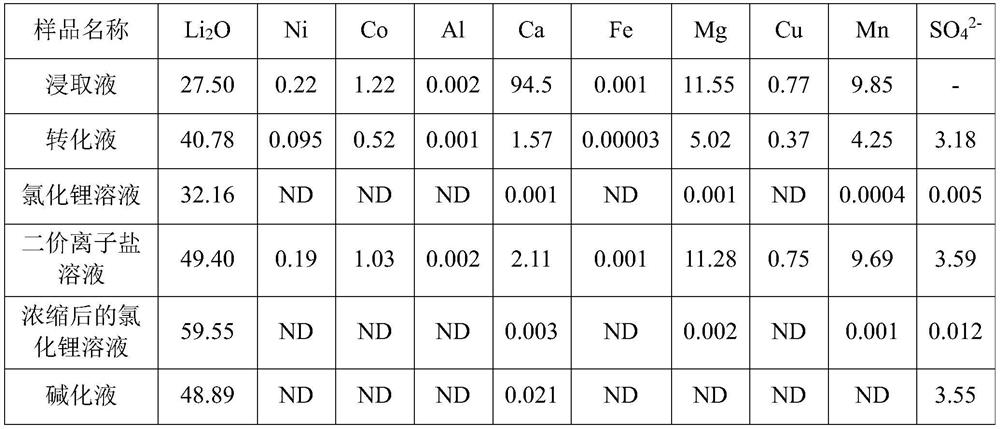

[0074] (1) Weigh 30g of slag, add 60mL of water, and stir evenly. The composition of the slag is shown in Table 1.

[0075] (2) Slowly add 55 g (about 48 mL) of industrial hydrochloric acid, stir to obtain a mixed acid material, add slag or hydrochloric acid, and control the final pH value after the reaction in step (3) to be 2-3.

[0076] (3) Keep the temperature at 85° C., and the reaction time is 4 hours.

[0077] (4) Vacuum-dry the mixed acid material at 190° C. for 2 hours, and carry out tail gas recovery treatment. The material is cooled to room temperature to obtain aluminum removal material.

[0078] (5) Mix the aluminum-removing material with 60 mL of water evenly, and stir for 1 hour to obtain a leaching slurry.

[0079] (6) Filtrate the leaching slurry to obtain filter residue and leaching solution, the ingredients of the leaching solution are shown in ...

Embodiment 2

[0092] Follow the steps below to extract lithium from the slag produced by pyro-recycling lithium batteries:

[0093] (1) Weigh 50 g of slag (see Table 1 for the composition of the slag), slowly add 150 g of industrial hydrochloric acid (about 130 mL), and stir to obtain a mixed acid material. Add slag or hydrochloric acid to control the final pH value to 2-3.

[0094] (2) The system naturally releases heat to 70° C., then slowly releases heat, and stirs the material for 2 hours without heating during the process to obtain a mixed acid material after the reaction.

[0095] (3) Vacuum-dry the reacted mixed acid material at 300° C. for 1 hour, and carry out tail gas recovery treatment. The material is cooled to room temperature to obtain aluminum removal material.

[0096] (4) Mix the aluminum-removing material with 150mL of water evenly, and stir for 2 hours to obtain a leaching slurry.

[0097] (5) Filtrating the leaching slurry to obtain a filter residue and a leaching solut...

Embodiment 3

[0106] Follow the steps below to extract lithium from the slag produced by pyro-recycling lithium batteries:

[0107] (1) Weigh 2000g of slag, add 2000mL of water, and mix well.

[0108] (2) Slowly add 6000g (about 5220mL) of industrial hydrochloric acid and stir to obtain a mixed acid material. Add slag or hydrochloric acid to control the final pH value to 2-3.

[0109] (2) The system is naturally exothermic to 75°C, then slowly cooled, and the material is stirred for 2 hours without heating during the process to obtain a mixed acid material after the reaction.

[0110] (3) Vacuum-dry the reacted mixed acid material at 250° C. for 1.5 h, and carry out tail gas recovery treatment. The material is cooled to room temperature to obtain aluminum removal material.

[0111] (4) Mix the aluminum-removing material with 2000 mL of water evenly, and stir for 3 hours to obtain a leaching slurry.

[0112] (5) Filtrating the leaching slurry to obtain a filter residue and a leaching sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com