The control system of the ejector device of the ultra-long stroke gantry mobile hydraulic press

A technology of ejection device and control system, which is applied in the field of hydraulic presses, can solve the problems of time wasting and the inability to realize automatic ejection of workpieces, etc., and achieve the effects of improving production efficiency and labor costs, solving high-intensity labor, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

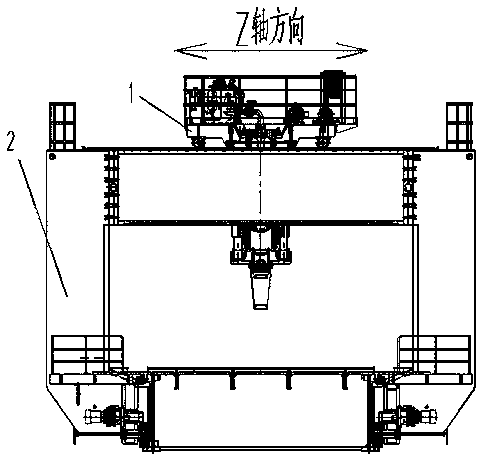

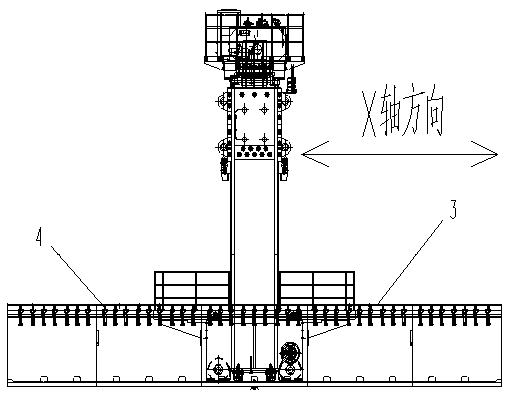

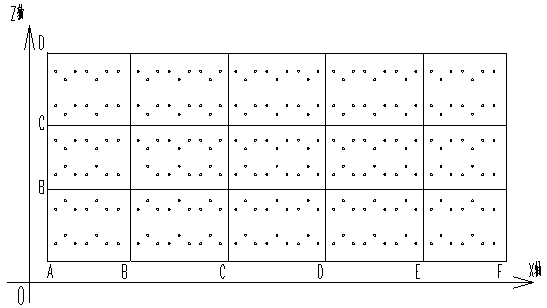

[0023] Such as Figure 4 Shown is a control system for the ejection device of a super-long-stroke gantry mobile hydraulic press, the control system is suitable for super-long-stroke gantry mobile hydraulic presses, and it includes the following steps:

[0024] Step 1. Confirmation of the X-axis coordinate information of cart 2

[0025] The cart operation switch 120 inputs a cart 2 running operation instruction to the editable logic controller 102 through the I / O quantity input module 103, and the editable logic controller 102 sends the instruction to the cart moving inverter 107, and the cart moving inverter 107 drives the cart right moving motor 112 attached to cart 2 and the cart left moving motor 113 to rotate, and drives cart 2 to move toward the cart reference point switch 119. When cart 2 touches the cart reference point After the switch 119, the cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com