Soil pressure testing device and method for anchor-plate-like retaining wall in different displacement modes

A test device and retaining wall technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. The effect of perfect monitoring system and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

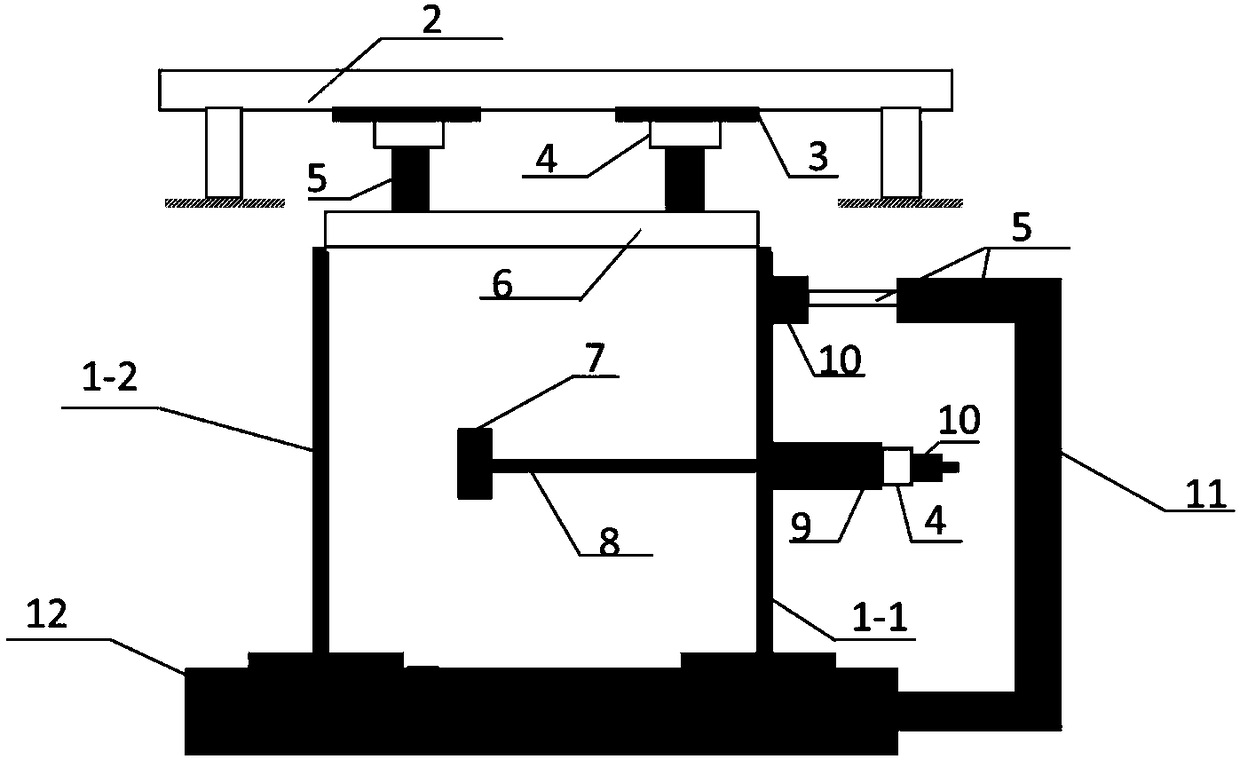

Embodiment 1

[0081] Sand can be used as the filling material for the back of the wall.

[0082] Assemble the base of the model tank of the test device, the soil retaining board, the slideway, the cantilever retaining wall and connect the hydraulic jack to apply lateral displacement through the wall connection, embed the earth pressure gauge on the cantilever retaining wall and install The electronic dial indicator and the earth pressure gauge are connected to the data acquisition box through the data line, and the data is recorded through the dynamic signal acquisition and analysis system, and then the sand is filled in layers. It is divided into three layers, each layer thickness is 20cm, 30cm, 30cm, after each layer of filling is completed, it will be compacted and leveled. Within 30cm of the side close to the buried instrument, it will be compacted with a rammer, and the other parts will be compacted manually with a ramming plate. After each layer is compacted, it will be measured by irr...

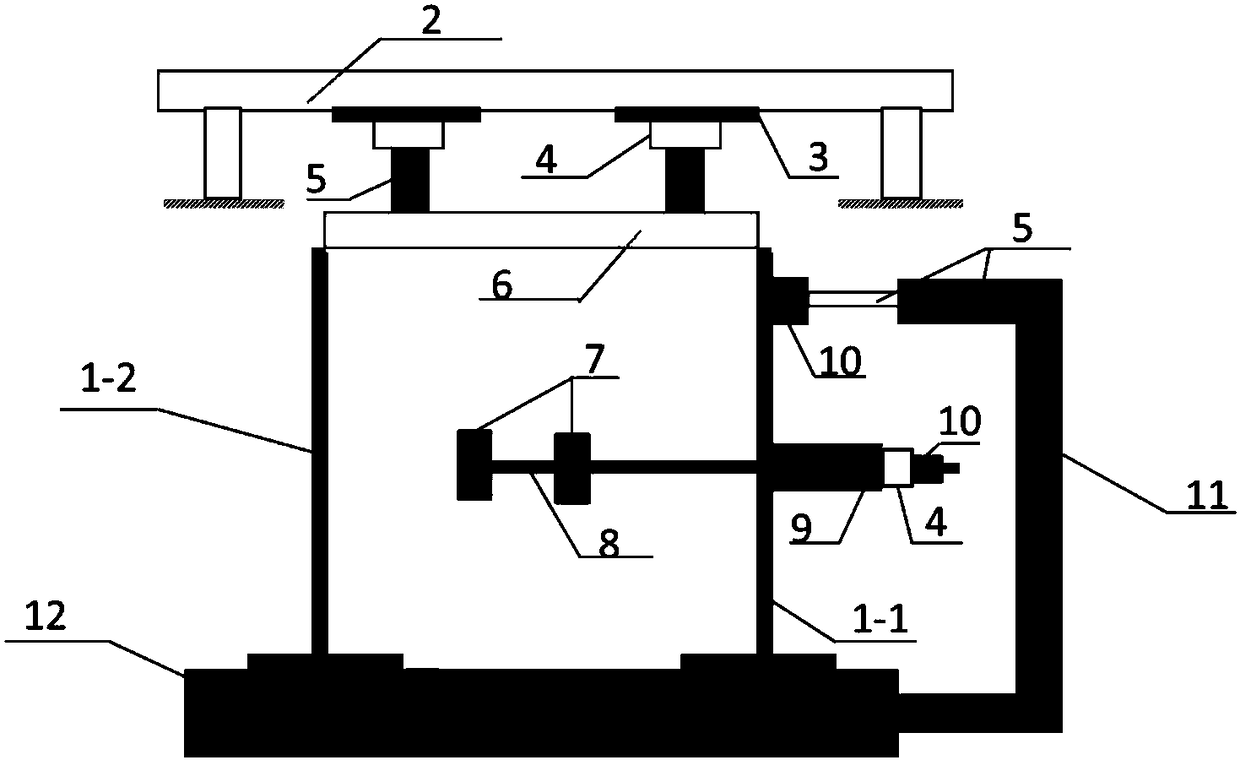

Embodiment 2

[0084] Sand can be used as the filling material for the back of the wall.

[0085] Assemble the base of the model tank, the retaining board, the slideway, the cantilever retaining wall and connect the hydraulic jack to apply lateral displacement through the wall connection, embed the earth pressure gauge on the cantilever retaining wall and install the electronic The dial indicator and the earth pressure gauge are connected to the data acquisition box through the data line, and the data is recorded through the dynamic signal acquisition and analysis system, and then the sand is filled in layers. It is divided into three layers, each layer thickness is 20cm, 30cm, After the completion of each layer of filling, tamping and leveling shall be carried out. Within 30 cm of the side close to the buried instrument, a rammer shall be used for tamping, and other parts shall be manually tamped with a tamping plate. After each layer is tamped, water irrigation shall be used to measure the ...

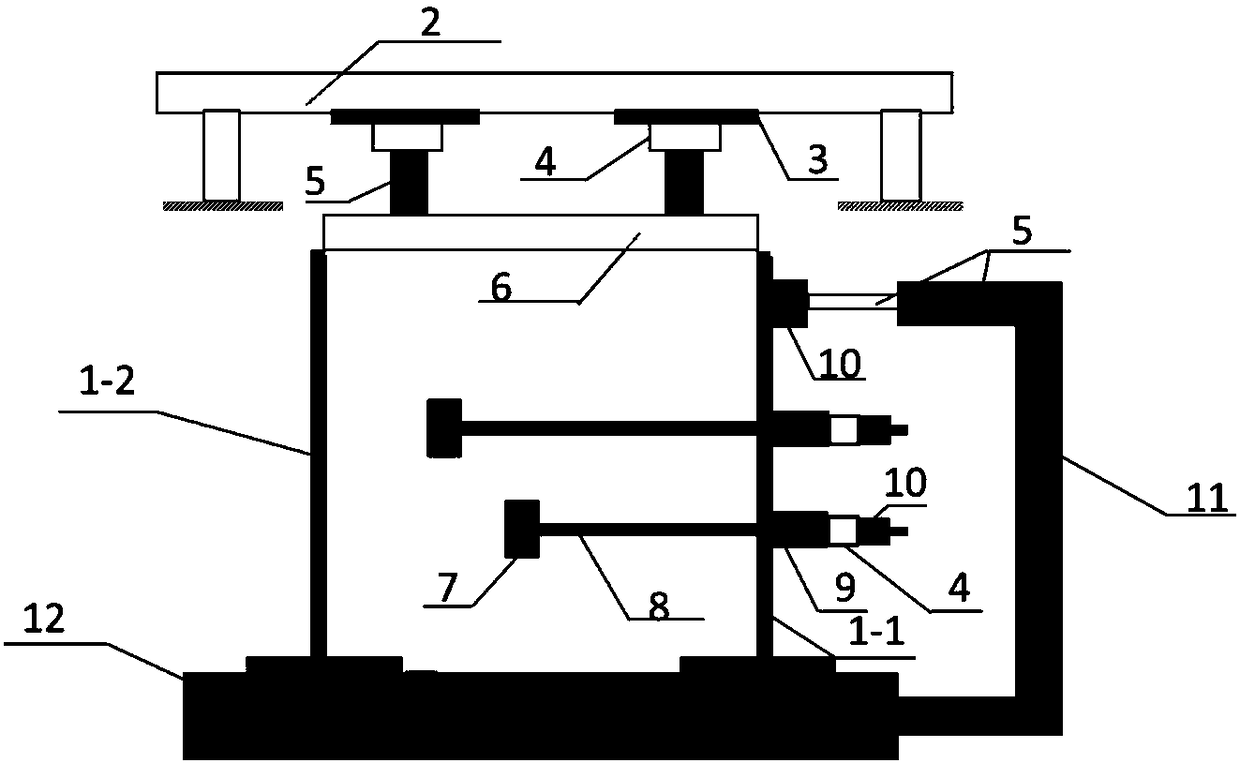

Embodiment 3

[0087] Sand can be used as the filling material for the back of the wall.

[0088] Assemble the base of the model tank, the retaining board, the slideway, the cantilever retaining wall and connect the hydraulic jack to apply lateral displacement through the wall connection, embed the earth pressure gauge on the cantilever retaining wall and install the electronic The dial indicator and the earth pressure gauge are connected to the data acquisition box through the data line, and the data is recorded through the dynamic signal acquisition and analysis system, and then the sand is filled in layers. It is divided into three layers, each layer thickness is 20cm, 30cm, After the completion of each layer of filling, tamping and leveling shall be carried out. Within 30 cm of the side close to the buried instrument, a rammer shall be used for tamping, and other parts shall be manually tamped with a tamping plate. After each layer is tamped, water irrigation shall be used to measure the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com