Commodity storage mechanism of vending machine and vending machine

A vending machine and commodity technology, applied in the direction of coinless or similar appliances, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve poor consumption experience, storage mechanism Large size, low space utilization, etc., to achieve the effect of easy application, improved stability, and improved space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

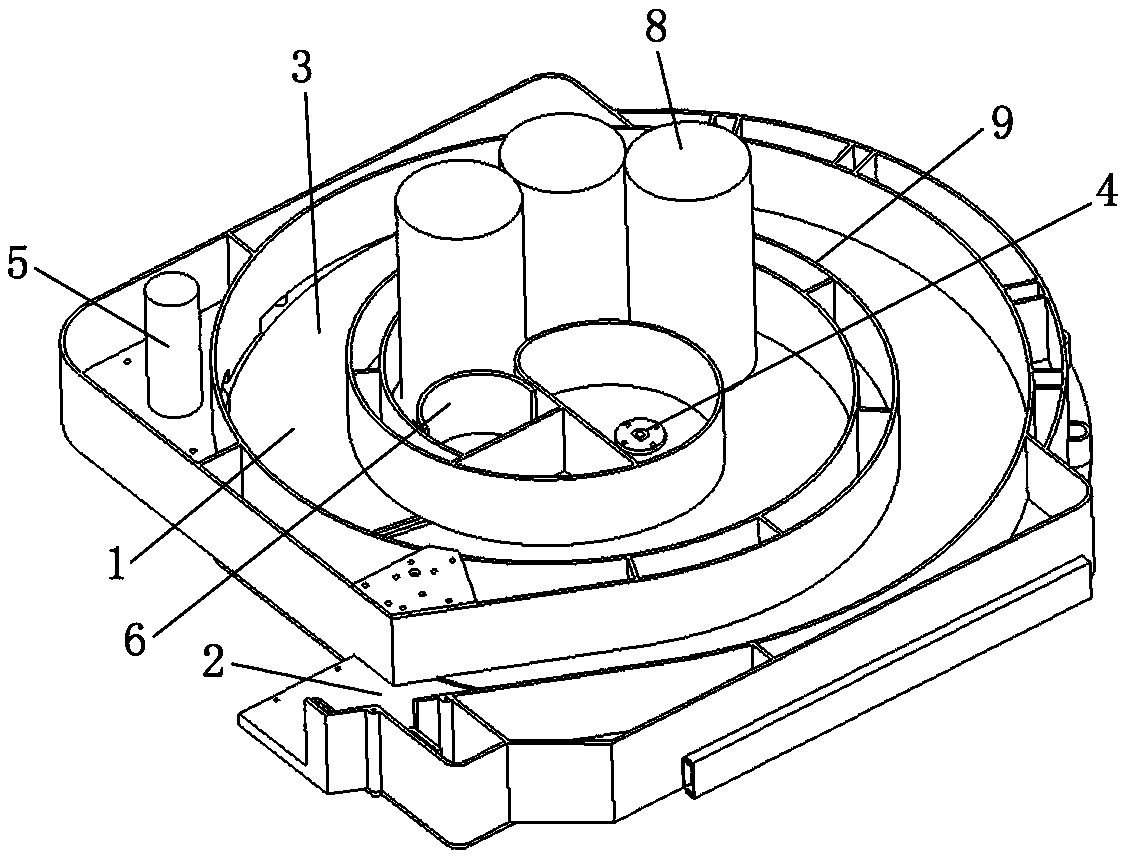

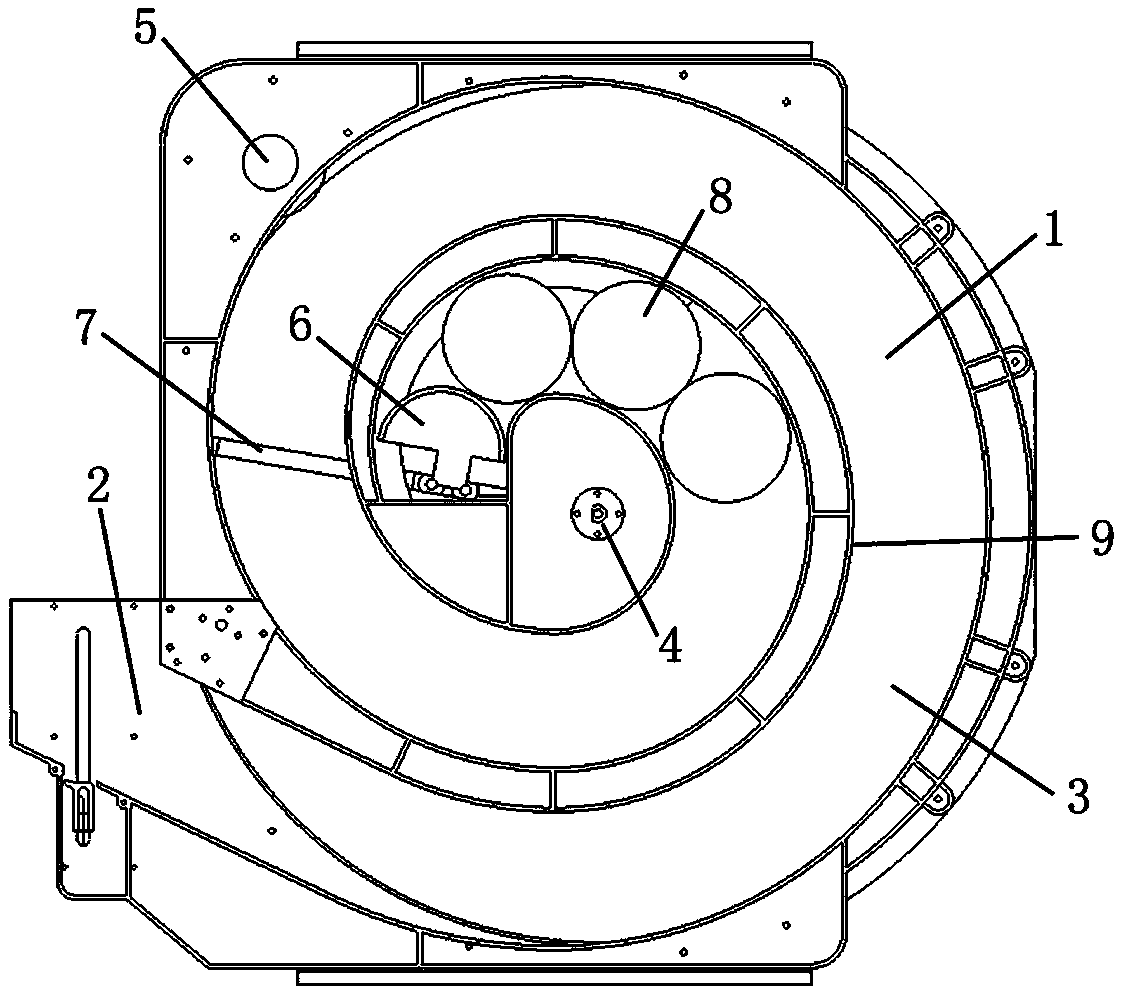

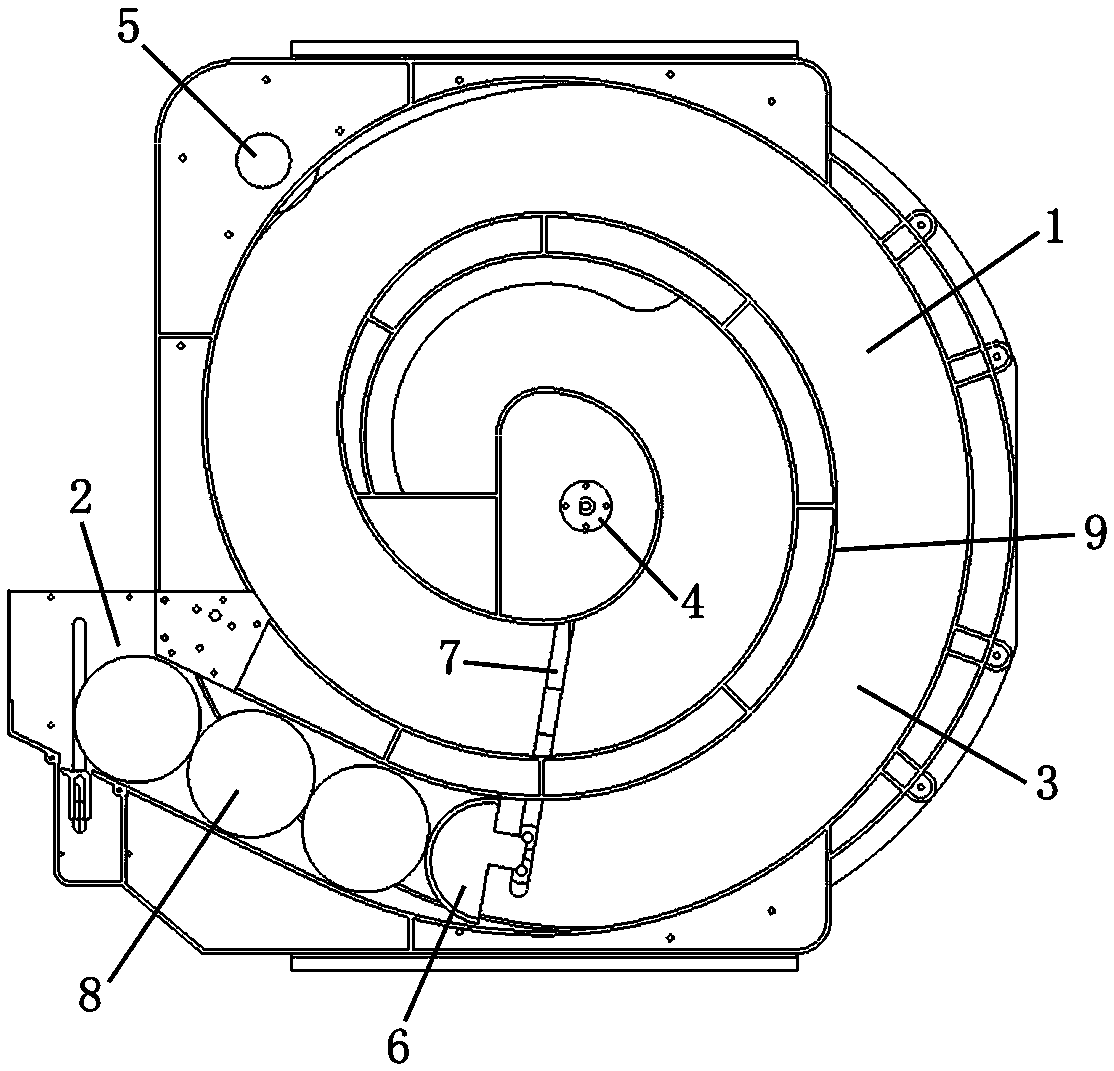

[0032] see Figure 1-Figure 6 As shown, the product storage mechanism of the automatic vending machine in this embodiment includes a storage tank 1 , a product outlet 2 , a carrying tray 3 and a product pushing device 6 .

[0033] Wherein, the storage tank 1 is arranged in a spiral shape on a plane, and the spiral storage tank 1 is divided into multiple layers by a partition 9 (all layers are on the same plane). The cargo outlet 2 communicates with the storage tank 1. In this embodiment, the cargo outlet 2 is located at the end of the spiral storage tank 1. Of course, the cargo outlet 2 can also be located on the side of the storage tank 1. And be communicated with storage tank 1, can export the goods 8 that move in place and get final product. The carrier plate 3 is located below the storage tank 1, that is, the carrier plate 3 is the bottom plate of the storage tank 1 for carrying the goods 8 in the storage tank 1, and the carrier plate 3 can be driven by a driving device ...

Embodiment 2

[0046] An automatic vending machine, including at least two layers of commodity storage mechanisms described in Embodiment 1 in the height direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com