Feeding system of wood board cutting machine

A technology of feeding system and cutting machine, which is applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems affecting the quality of bamboo and wood flooring, affecting the uniformity of product size, and affecting the quality of bamboo wood boards, etc., to achieve reduction Interference from external factors, high operational stability, and good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

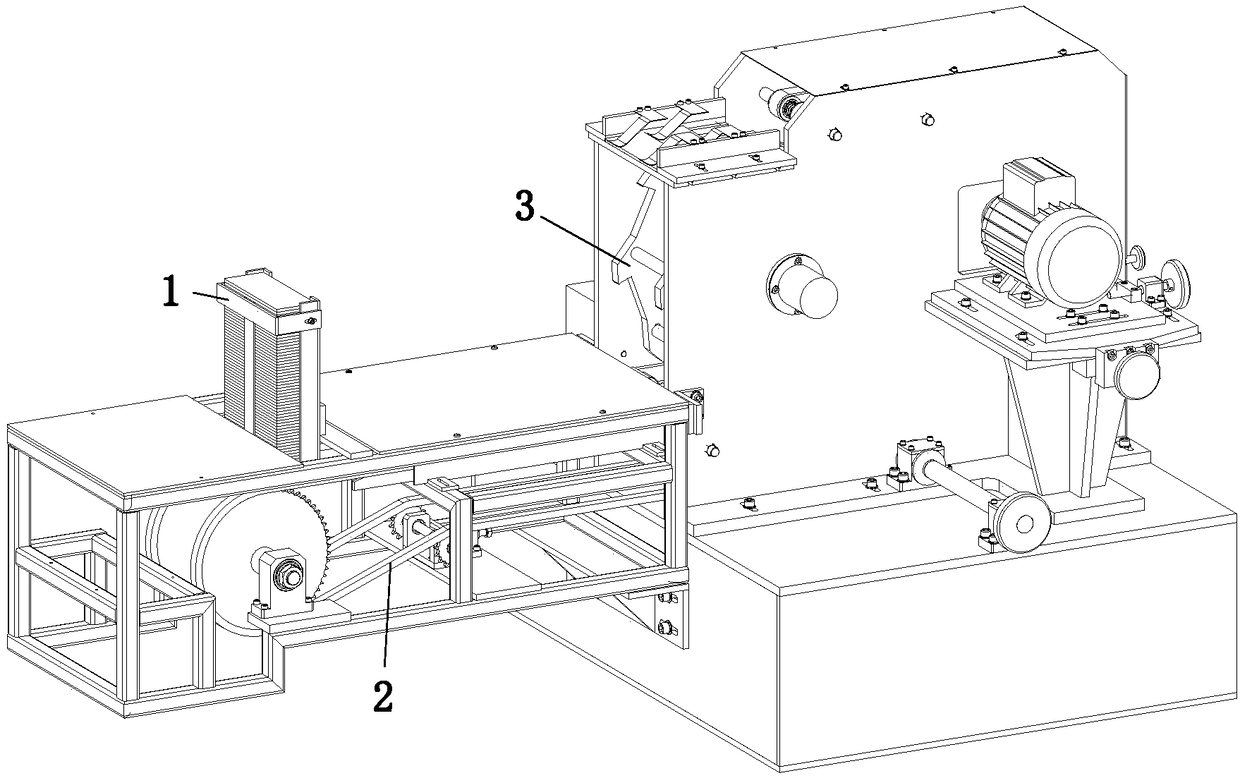

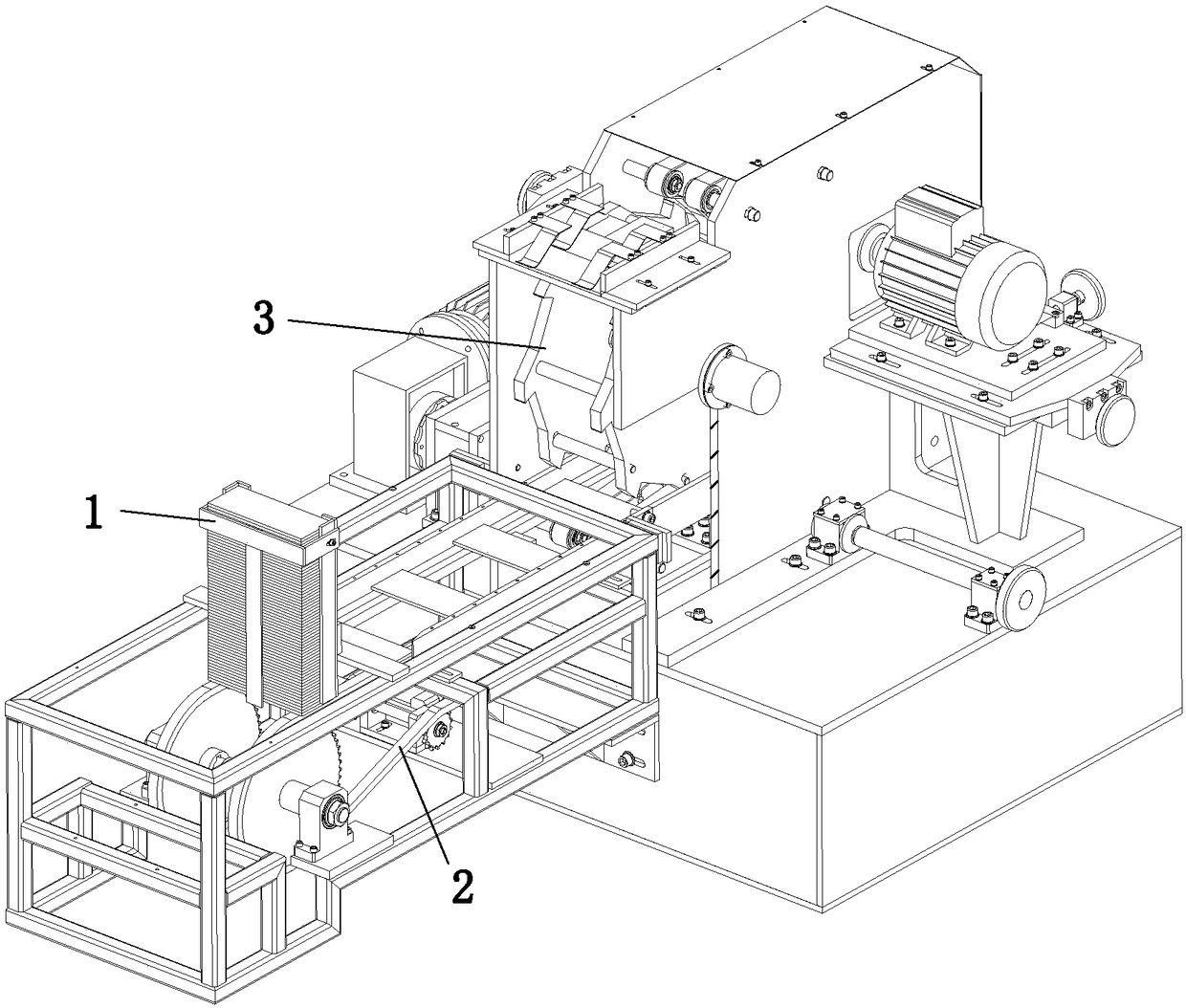

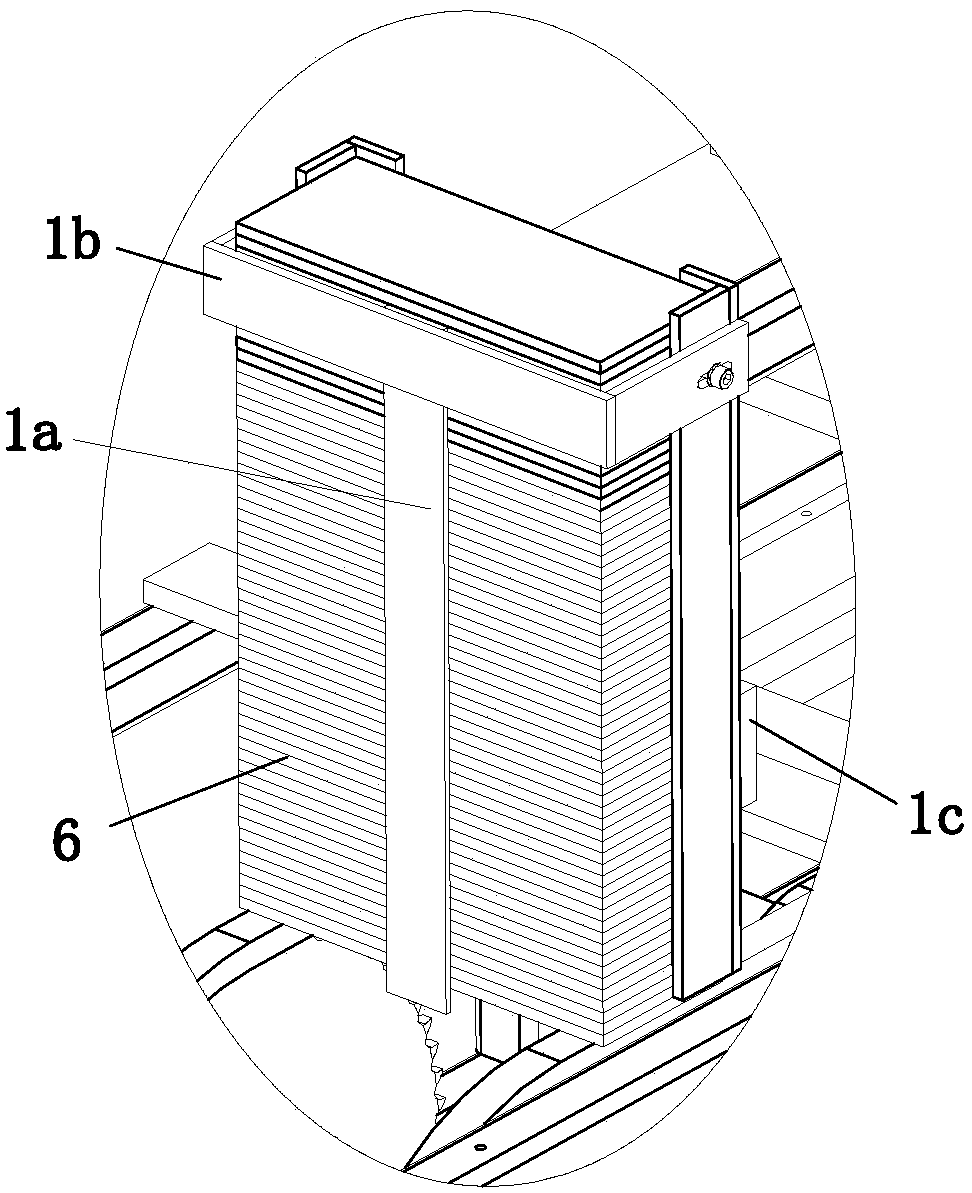

[0022] refer to Figure 1 to Figure 6 The wood cutting machine shown includes a feeding system and a cutting system that cooperate with each other. The feeding system includes a hopper 1 and a conveying device 2. The hopper 1 is erected on the conveying device 2. A wooden board 6 is provided under the hopper 1 for internal placement. Can fall on the first opening on the conveying device 2, the hopper 1 is provided with a second opening on the side corresponding to the conveying direction forward of the conveying device 2, the height of the second opening is the same as the thickness of a single plank 6, the cutting system includes a rotating device 3. The pressing device 4 and the cutting device 5, the rotating device 3 is arranged at the end prescription of the conveying device 2, the pressing device 4 is arranged ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap