Copper-carved enamel glassware and manufacturing method

A technology of glassware and enamel, applied in the field of handicrafts, can solve problems such as high cost, long construction period, and complicated firing process, achieve high market potential and economic value, and reduce the use of copper materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

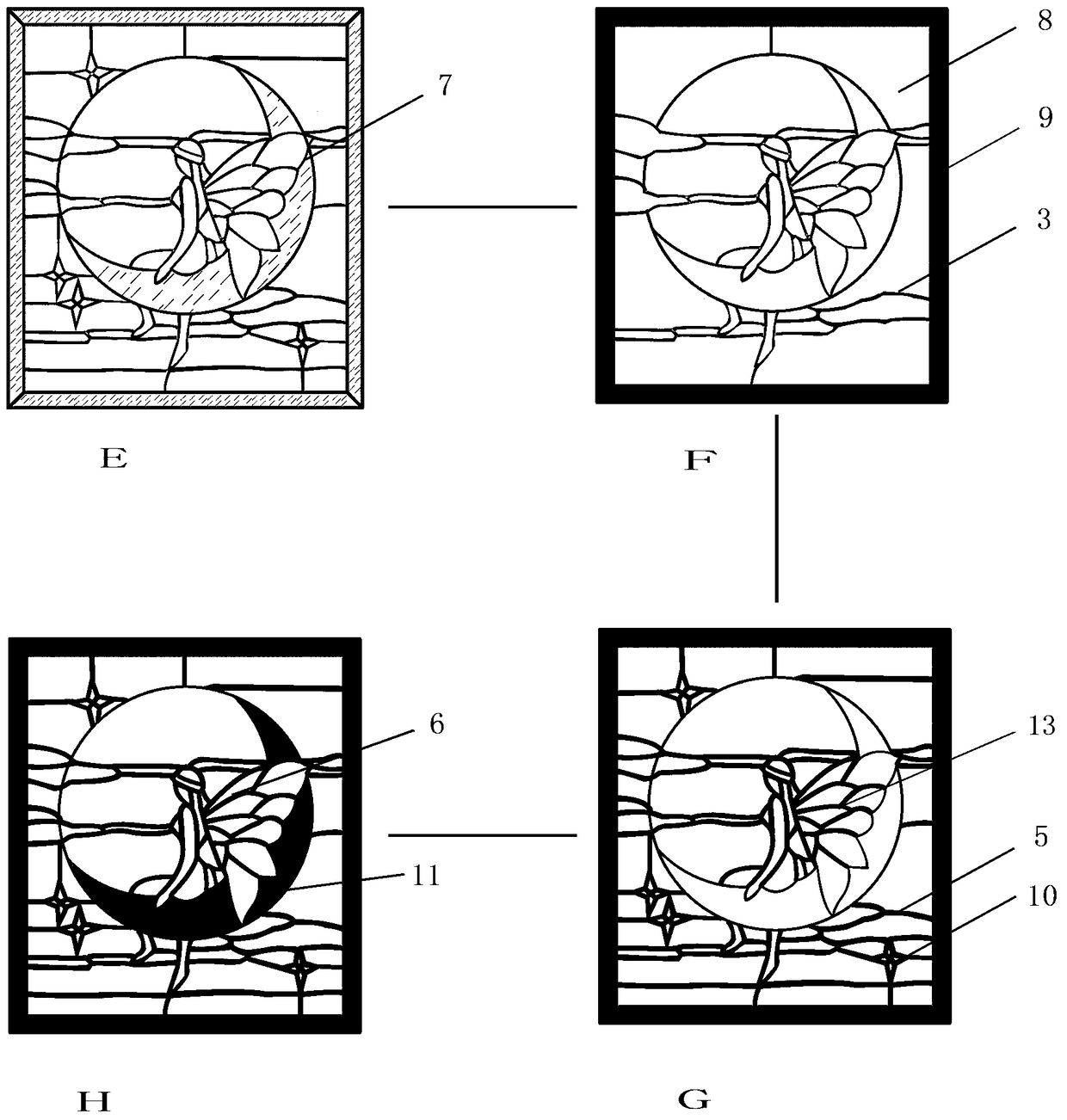

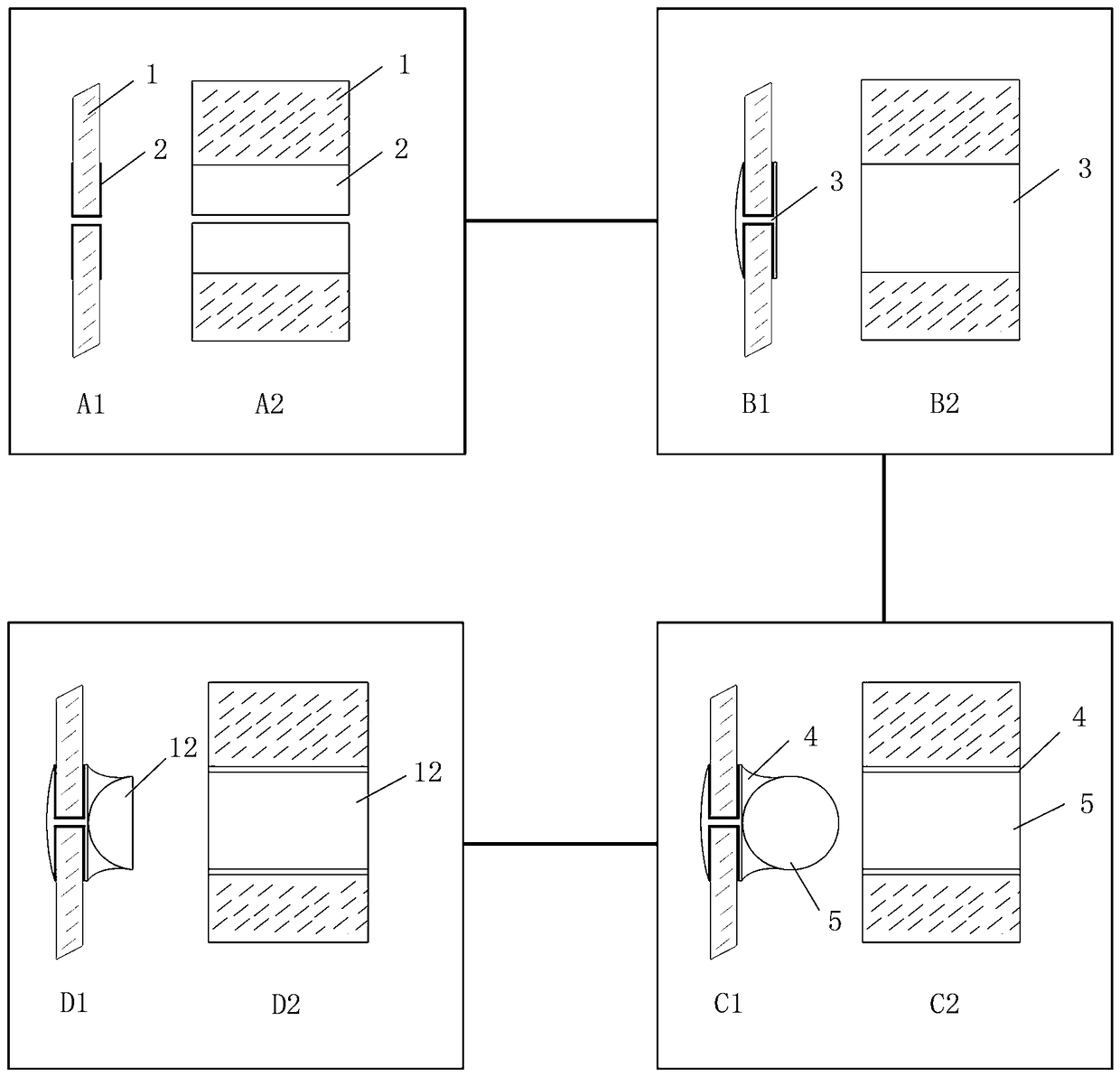

[0024] Implementation example 1 such as figure 1 Shown is the process flow of the present invention when it is used to make copper engraved and enamel glass decorative paintings, including: plane design figure 7, glass tire 8, copper frame 9, lead tin base line 3, main copper base line 5, auxiliary copper base line 10. Bronze carving pattern 6, copper carving member 11, copper baseline plane body 12, copper filigree pattern 13; first make a plan design figure 7, as shown in figure E; then make an enamel glass body 8 by the encasement process to form lead The tin base line 3, and the copper frame 9 is welded to the edge of the enamel glass substrate 8, as shown in Figure F; then the main copper base line 5 is welded to the lead-tin base line 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com