A carbonization reactor and a method for preparing nano-calcium carbonate with small particle size, high dispersion and low oil absorption value

A nano calcium carbonate, high dispersibility technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of poor nano calcium carbonate dispersibility, high oil absorption value, low oil absorption value, etc., to achieve good dispersion, uniform and stable crystal nucleus , to ensure the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

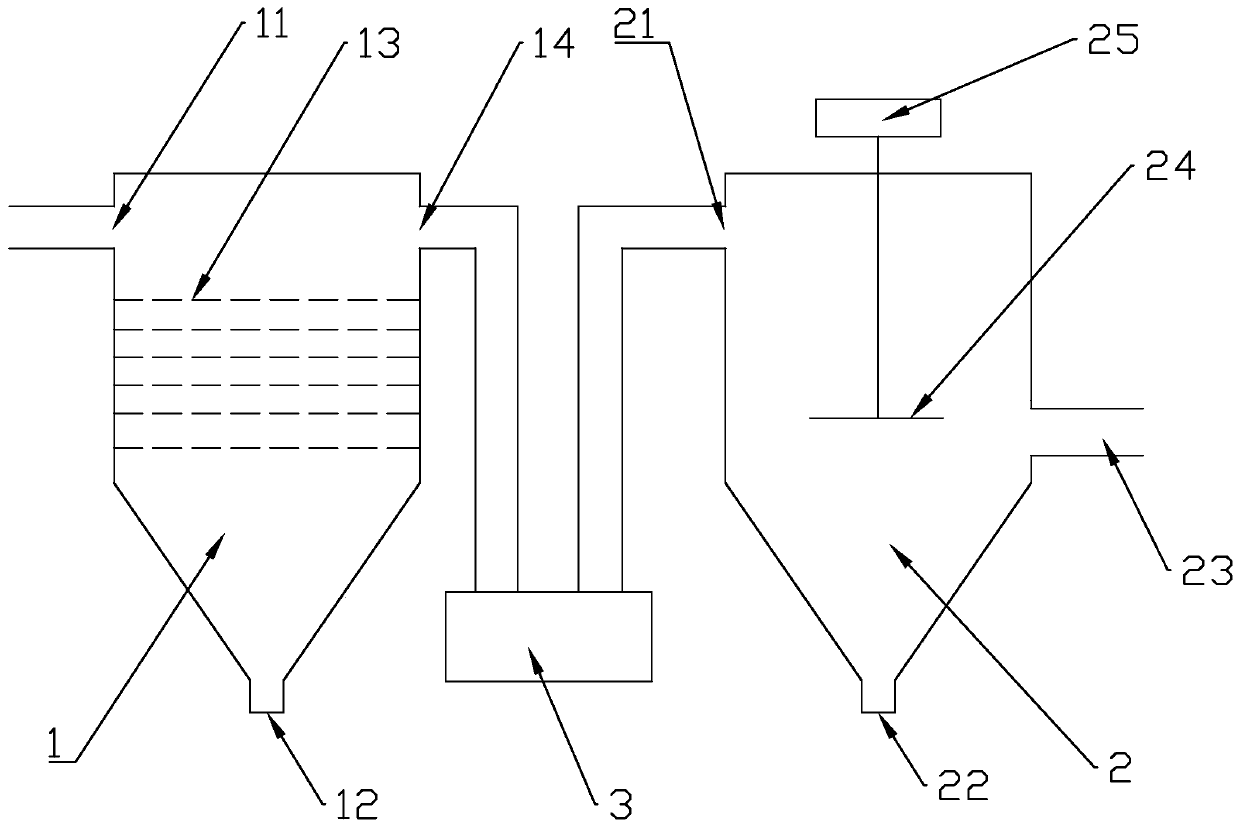

[0039] Such as figure 1 The shown carbonization reactor of the present invention comprises a liquid film nucleator 1 and a crystal grower 2, the upper end of the liquid film nucleator 1 is provided with a slurry inlet-11 and a slurry outlet-14, and the lower end is provided with The gas inlet one 12, the slurry inlet one 11 and the slurry outlet one 14 are respectively located on both sides of the liquid film nucleator 1, and the liquid film nucleator 1 is also provided with a gas distributor 13; the crystal grower 2 The upper end is provided with a slurry inlet 2 21, the lower end is provided with a gas inlet 22 and a slurry outlet 2 23, the crystal grower 2 is also provided with a stirrer 24, and the crystal grower 2 is provided with a motor 25 connected with the stirrer 24 , the first slurry outlet 14 and the second slurry inlet 21 are communicated through the pump 3, and the first slurry inlet, the second slurry inlet, the first gas inlet and the second gas inlet are all e...

Embodiment 2

[0056] The method for preparing nano-calcium carbonate with small particle size, high dispersion and low oil absorption value by using the carbonization reactor comprises the following steps:

[0057] 1. The lime is calcined, and the lime should be partially burned during the calcination process, so that the whiteness of the calcined lime is above 95%;

[0058] 2. Select lime particles with a whiteness of more than 95% through the color sorter and add them to the digester, add water to carry out the digestion reaction to obtain calcium hydroxide coarse slurry, and pass the calcium hydroxide coarse slurry through 100 mesh, 200 mesh, and 325 mesh in sequence , 500 mesh sieves to obtain calcium hydroxide essence;

[0059] 3. Add water to the calcium hydroxide refined slurry to adjust the mass percentage concentration to 7%, and exchange heat with cooling water below 7°C through a plate heat exchanger, so that the temperature of the calcium hydroxide refined slurry is reduced to 8...

Embodiment 3

[0071] The method for preparing nano-calcium carbonate with small particle size, high dispersion and low oil absorption value by using the carbonization reactor comprises the following steps:

[0072] 1. The lime is calcined, and the lime should be partially burned during the calcination process, so that the whiteness of the calcined lime is above 95%;

[0073] 2. Select lime particles with a whiteness of more than 95% through the color sorter and add them to the digester, add water to carry out the digestion reaction to obtain calcium hydroxide coarse slurry, and pass the calcium hydroxide coarse slurry through 100 mesh, 200 mesh, and 325 mesh in sequence , 500 mesh sieves to obtain calcium hydroxide essence;

[0074] 3. Add water to the calcium hydroxide refined slurry to adjust the mass percentage concentration to 8%, and exchange heat with cooling water below 7°C through a plate heat exchanger, so that the temperature of the calcium hydroxide refined slurry is reduced to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com