A kind of emulsion for coating water treatment filler based on microbial fermentation broth and its preparation and use method

A microbial fermentation liquid and water treatment technology, applied in the field of water treatment, can solve the problems of poor biological affinity, great impact on water quality, and high production costs, and achieve the effects of avoiding organic pollution, high production operability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

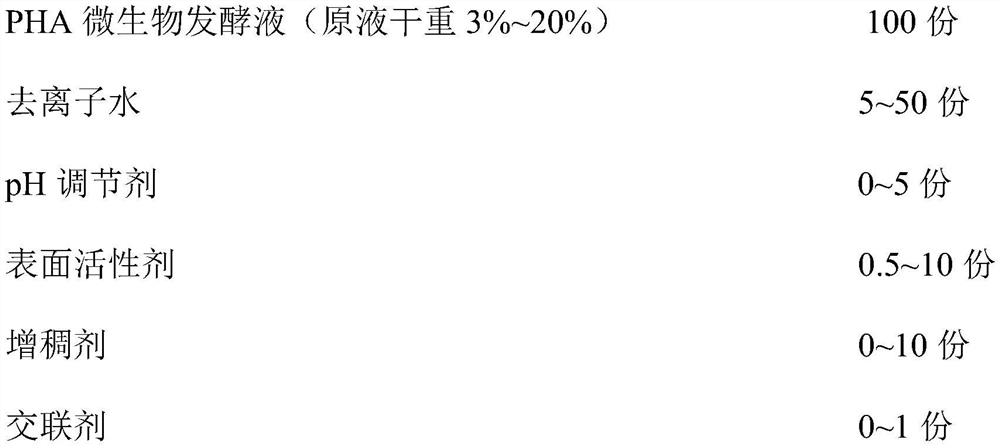

Method used

Image

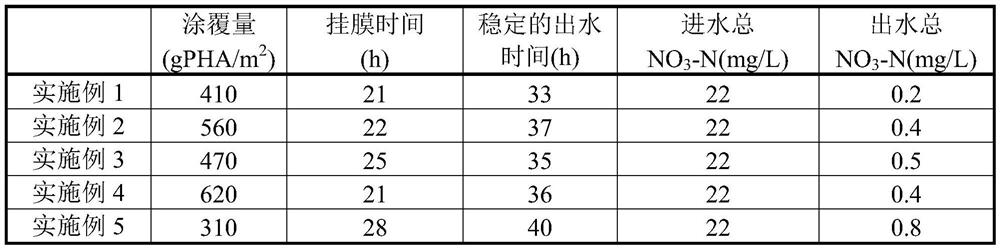

Examples

Embodiment 1

[0039] Add 1 L of poly-3-hydroxybutyrate microbial fermentation broth (stock solution dry weight 10%), add an equal volume of 1 L deionized water to wash, and stir at 25° C. for 0.5 h. After the stirring, the mixture was centrifuged in a centrifuge at a speed of 3000r / min for 5min at a centrifugation temperature of 25°C, and the supernatant was removed to obtain a centrifuged solid phase with a dry weight of 31%.

[0040] Add 100ml of deionized water to the centrifuged solid phase, stir at 25°C for 0.5h, heat to 40°C, add sodium hydroxide solution and sodium phosphate to adjust the pH to 9-10, add 0.4g of sodium lauryl sulfate , 1g calcium carbonate, add 1ml soybean oil to defoam when bubbles appear. Stir at a constant temperature of 40° C. for 1 h, and add sulfuric acid solution to adjust the pH=7. Add 0.05 g of thickener methyl cellulose to adjust the viscosity of the biological fermentation emulsion, and control the viscosity to 15-30 Pa·s. Add 1 g of preservative formald...

Embodiment 2

[0043] Add 1 L of poly-3-hydroxybutyrate-3-hydroxyvalerate microbial fermentation broth (stock solution dry weight 12%), add an equal volume of 1 L deionized water, and stir at 30° C. for 0.5 h. After the stirring, the mixed liquid was centrifuged in a centrifuge at a speed of 3000 r / min for 8 min, and the supernatant was removed to obtain a centrifuged solid phase with a dry weight of 38%.

[0044] Add 150ml of deionized water to the centrifuged solid phase, stir at 30°C for 0.5h, and heat to 45°C. Add sodium hydroxide and sodium phosphate to adjust pH=9 to 10, add 1g sodium dodecylsulfonate, 0.5g talcum powder, 0.1g borax, and add 1ml soybean oil to defoam when bubbles appear. Stir at a constant temperature of 45°C for 1 h, and add sulfuric acid to adjust the pH to 7. Adding 0.2 g thickener starch to adjust the viscosity of the biological fermentation emulsion to 15-30 Pa·s. Add 1.5 g of preservative formaldehyde, and stir at 45° C. for 0.5 h to prepare poly-3-hydroxybutyr...

Embodiment 3

[0047] Add 1 L of poly-3-hydroxybutyrate-4-hydroxybutyrate microbial fermentation broth (stock liquid dry weight 8%), add an equal volume of 1 L deionized water, and stir at 30° C. for 0.5 h. After the stirring, the mixture was centrifuged in a centrifuge at a speed of 3500 r / min for 8 min, and the supernatant was removed by centrifugation to obtain a centrifuged solid phase with a dry weight of 30%.

[0048] Add 80ml of deionized water to the centrifuged solid phase, stir at 30°C for 0.5h, and heat to 50°C. Ammonia water and sodium phosphate were added to adjust the pH=8 to 9, and 5 g of sodium stearate and 2 g of talcum powder were added. When bubbles appear in the emulsion, add 0.1 g of silicone defoaming liquid to defoam. Stir at a constant temperature of 50° C. for 2 h, and add sulfuric acid to adjust the pH to 7. Add 0.02g of viscosifier hydroxyethyl cellulose to control the viscosity to 2.5-5Pa·s. Add 0.5 g of preservative sodium acetate, and continue to stir at 50° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com