Distribution matrix designing method for increasing utilizing rate of large blast furnace gas

A technology of distributing matrix and blast furnace gas, which is applied in the field of blast furnace, can solve the problems of difficult blast furnace, high fuel consumption cost of blast furnace, high carbon monoxide utilization rate, etc., and achieve the reduction of production cost, improvement of blast furnace carbon monoxide utilization rate, and reduction of fuel ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the specific implementation process, a kind of distribution matrix design method of the present invention improves the utilization rate of large-scale blast furnace gas, and the specific design is as follows:

[0037] (1) Cloth matrix:

[0038] Table 1 Cloth matrix parameter table

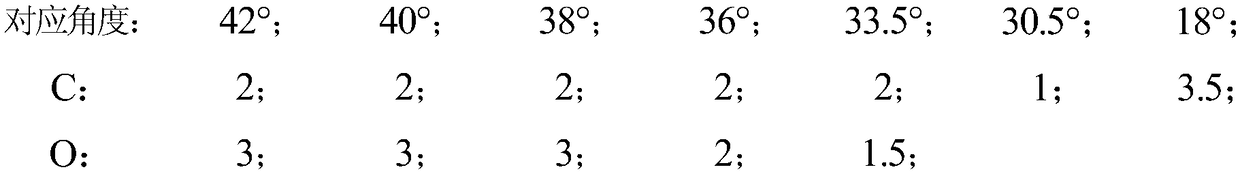

[0039]

42°

40°

38°

36°

33.5°

30.5°

18°

C

2

2

2

2

2

1

3.5

O

3

3

3

2

1.5

[0040] Material line: C: 1.3 meters; O: 1.5 meters;

[0041] (2) Mineral batch: 88 tons, coke batch 18 tons;

[0042] (3) Cross temperature measurement temperature: edge 80℃~120℃, center 450℃~550℃;

[0043] (4) Gas composition: the main components are: CO, CO 2 , N 2 、H 2 、CH 4 etc., of which CO 24.11%, CO 2 23.40%, gas utilization rate 49.25%.

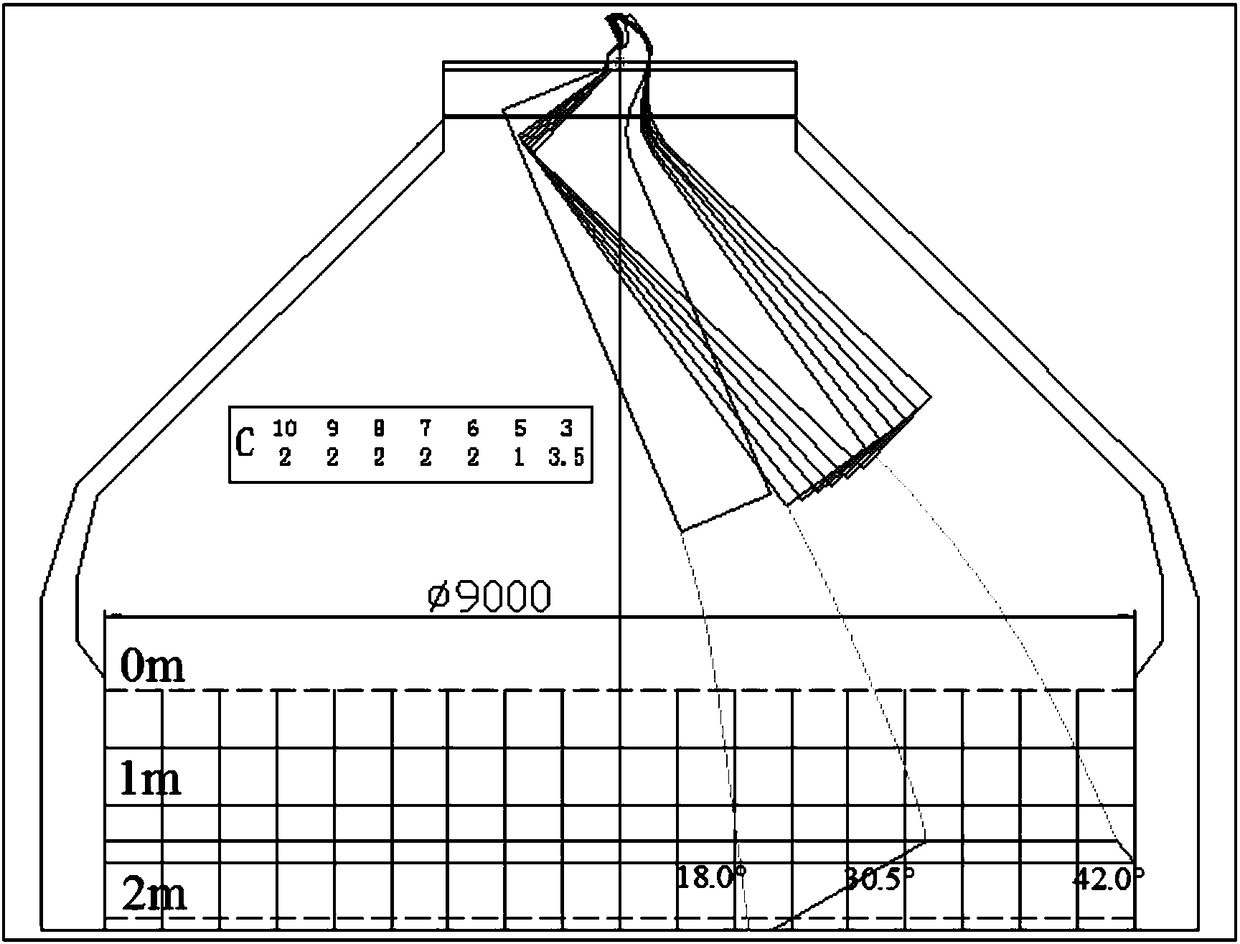

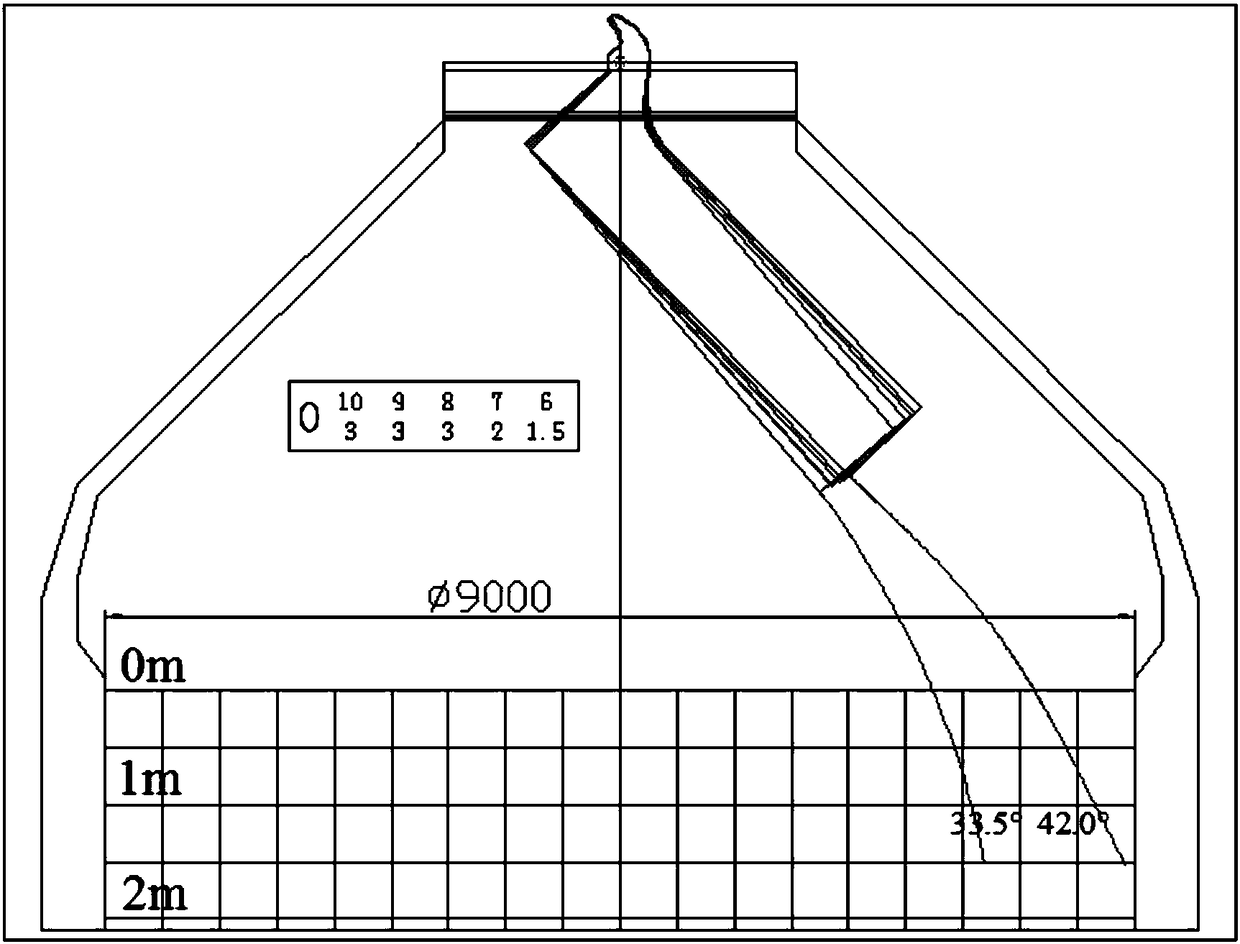

[0044] (1) if figure 1 Shown, control the falling point position of coke, specifically as follows:

[0045] Table 2 Partial parameter list of coke distribution matrix

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com