Method for improving screw drilling tool use performance and super screw drilling tool

A screw drilling tool and performance technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reduced service life of screw drilling tools and drill bits, axial pressure and vibration damage of screw drilling tools, and improve drilling efficiency , improve the ability to resist axial pressure and anti-rotational centrifugal force, and improve the effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

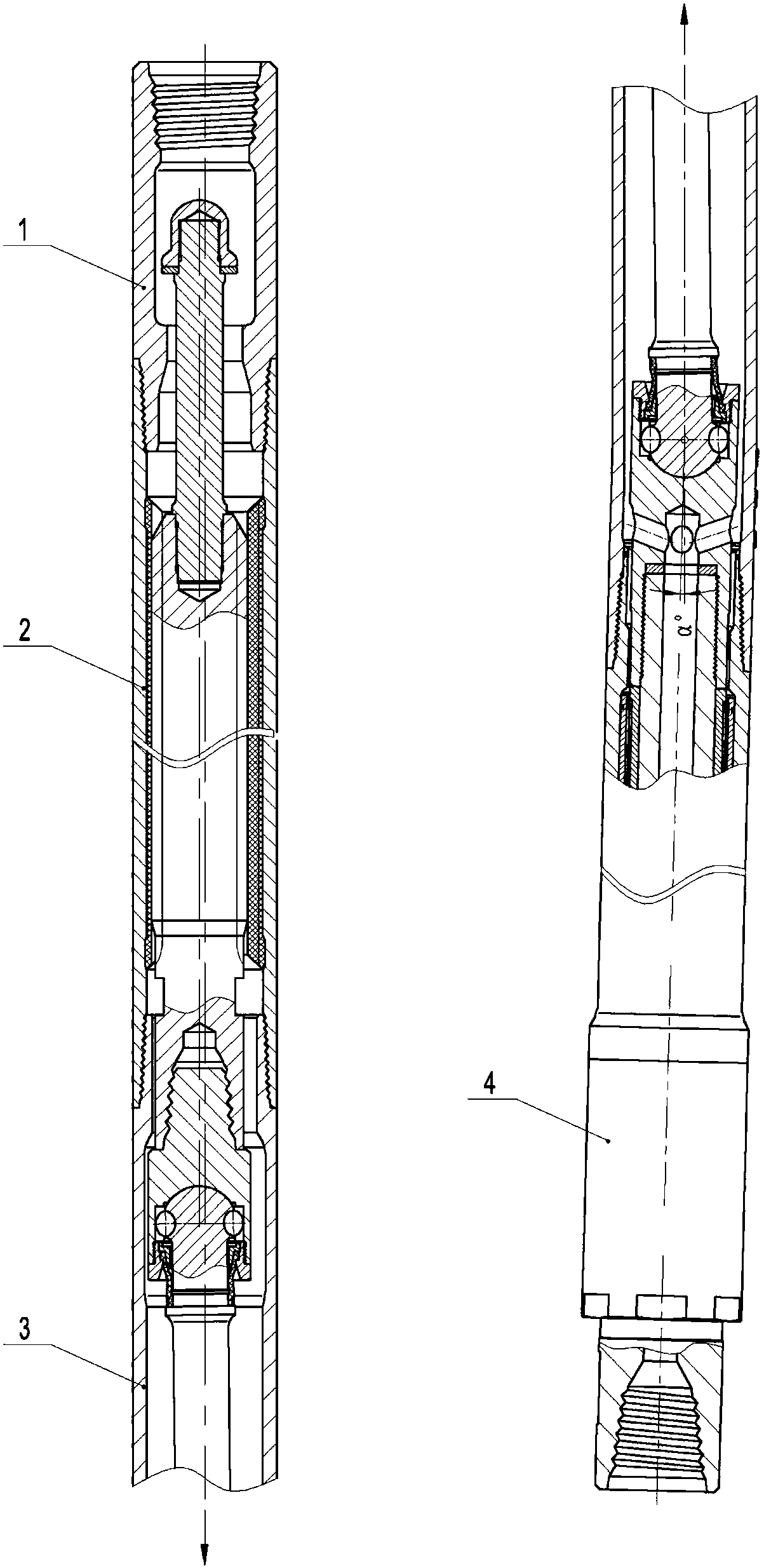

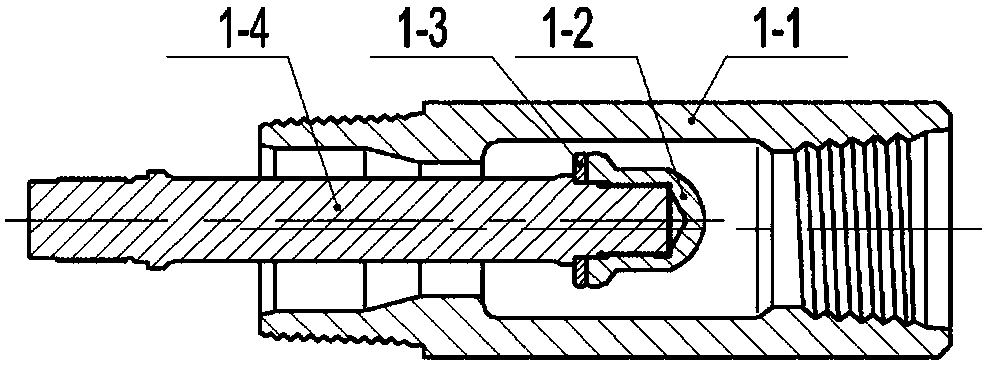

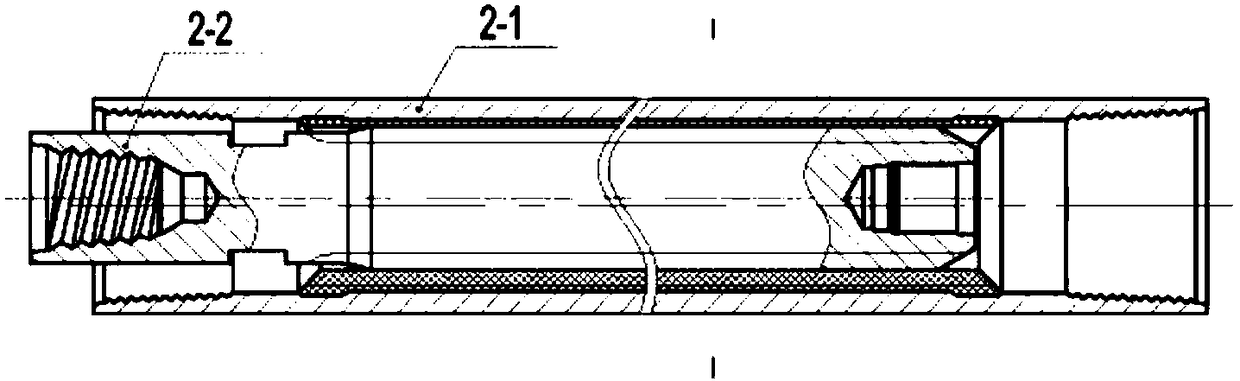

[0032]Embodiments of the present invention: a method for improving the performance of a screw drilling tool, the method improves the performance of the screw drilling tool by improving the motor assembly 2 and the cardan shaft assembly 3 in the screw drilling tool; wherein the motor assembly The stator 2-1 and the rotor 2-2 are combined in a spiral structure, thereby prolonging the lead of the motor assembly 2, increasing the number of stages of the motor assembly and the number of heads of the stator and rotor, and improving the efficiency of the mud pump system. Displacement, so that the output torque and speed of the motor assembly 2 can be increased; at the same time, a certain curvature is set at the lower end of the cardan shaft outer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com