A flexible connection device at the tail end of a pressurized oil cylinder and a rotary drilling rig

A pressurized oil cylinder, flexible connection technology, applied in drill pipe, drill pipe, earthwork drilling and other directions, can solve problems such as deviation, pressurized oil cylinder barrel, long piston rod, etc., to improve service life, improve working conditions, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

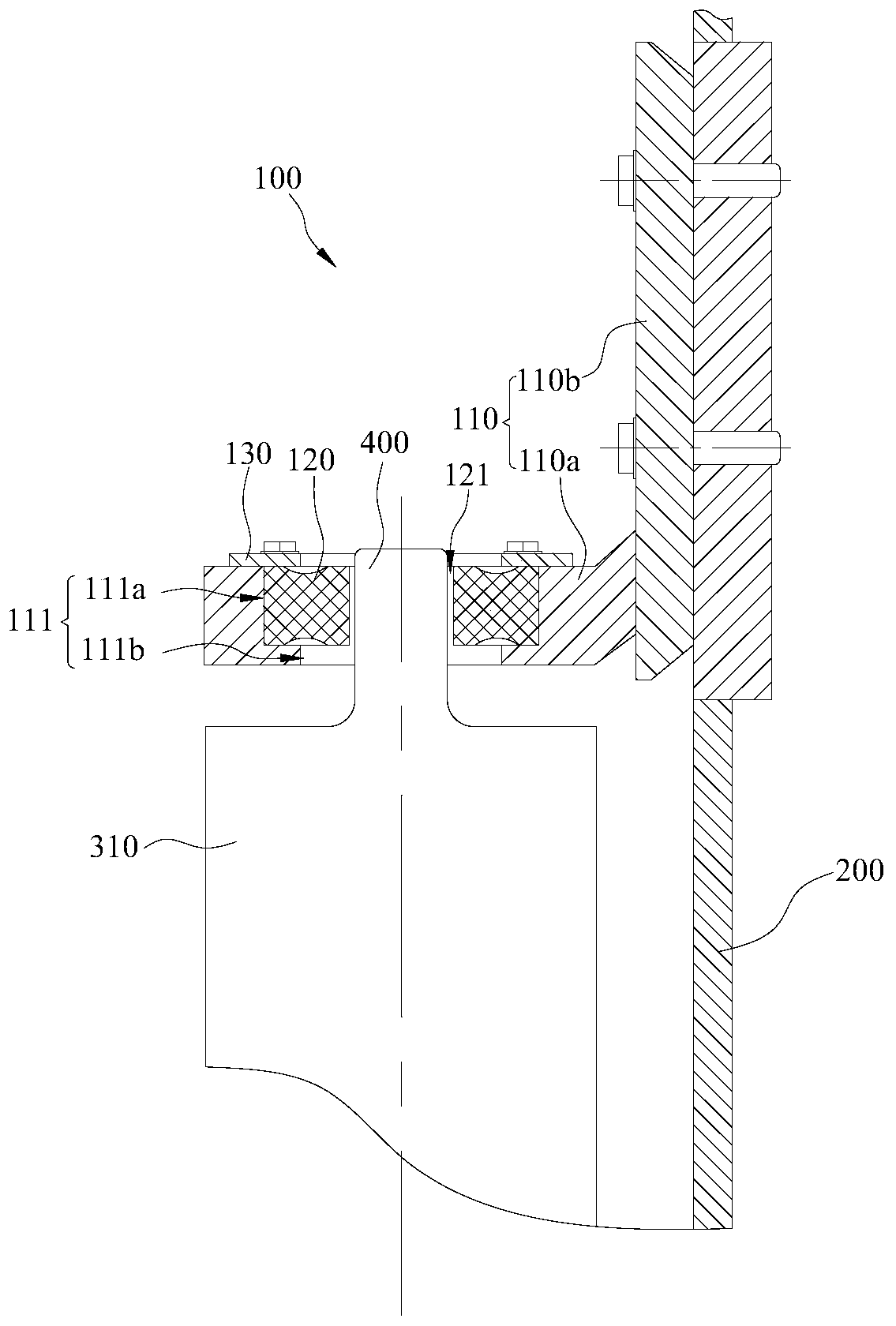

[0030] Embodiment 1, with reference to figure 1 and figure 2 as shown,

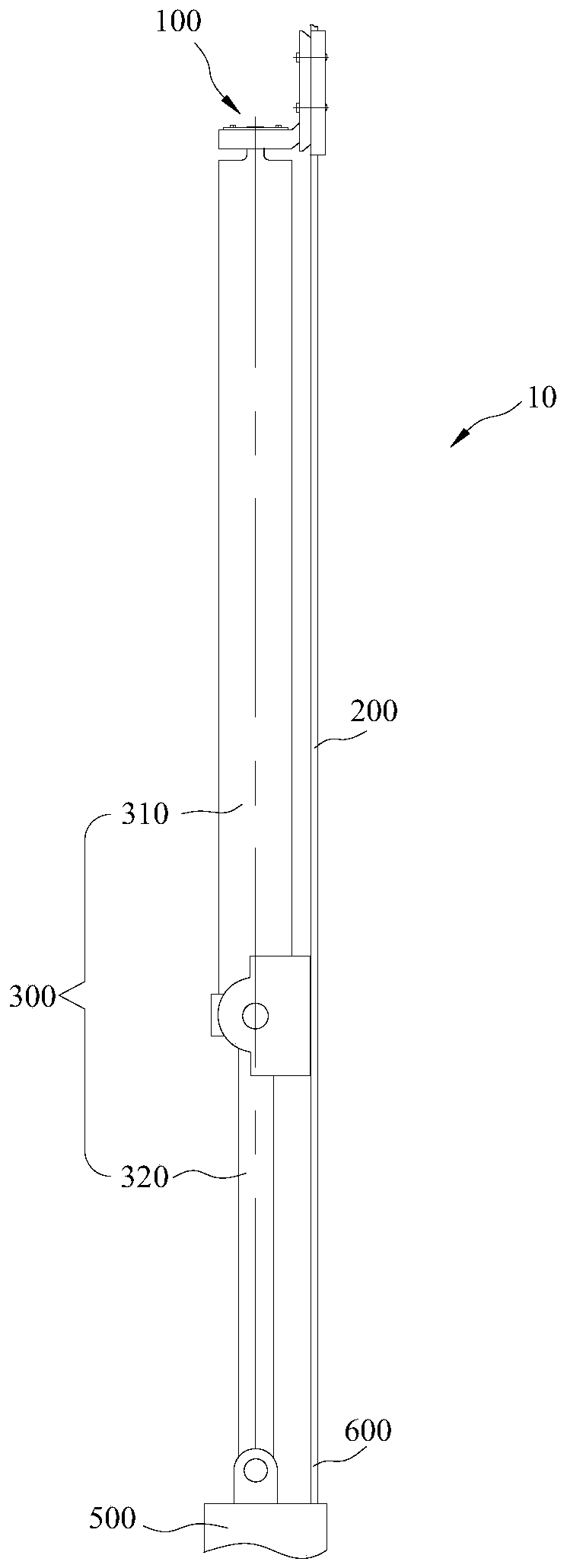

[0031] see figure 1 , figure 1 Shown is a partial schematic view of the rotary drilling rig 10 provided in this embodiment. This type of rotary drilling rig 10 belongs to the cylinder pressurization method, which includes a flexible connection device 100 at the tail end of the pressurized cylinder, a mast 200 , a pressurized cylinder 300 , a power head carriage 500 and a guide rail 600 .

[0032] The guide rail 600 is fixed on the mast 200 , and the length direction of the guide rail 600 is the same as the length direction of the mast 200 . The power head carriage 500 is slidably connected to the guide rail 600 . The pressurized oil cylinder 300 includes a cylinder barrel 310 and a piston rod 320 , and the piston rod 320 is connected with the power head carriage 500 . The piston rod 320 protrudes from the head of the cylinder 310 and can move telescopically relative to the cylinder 310 under the act...

Embodiment 2

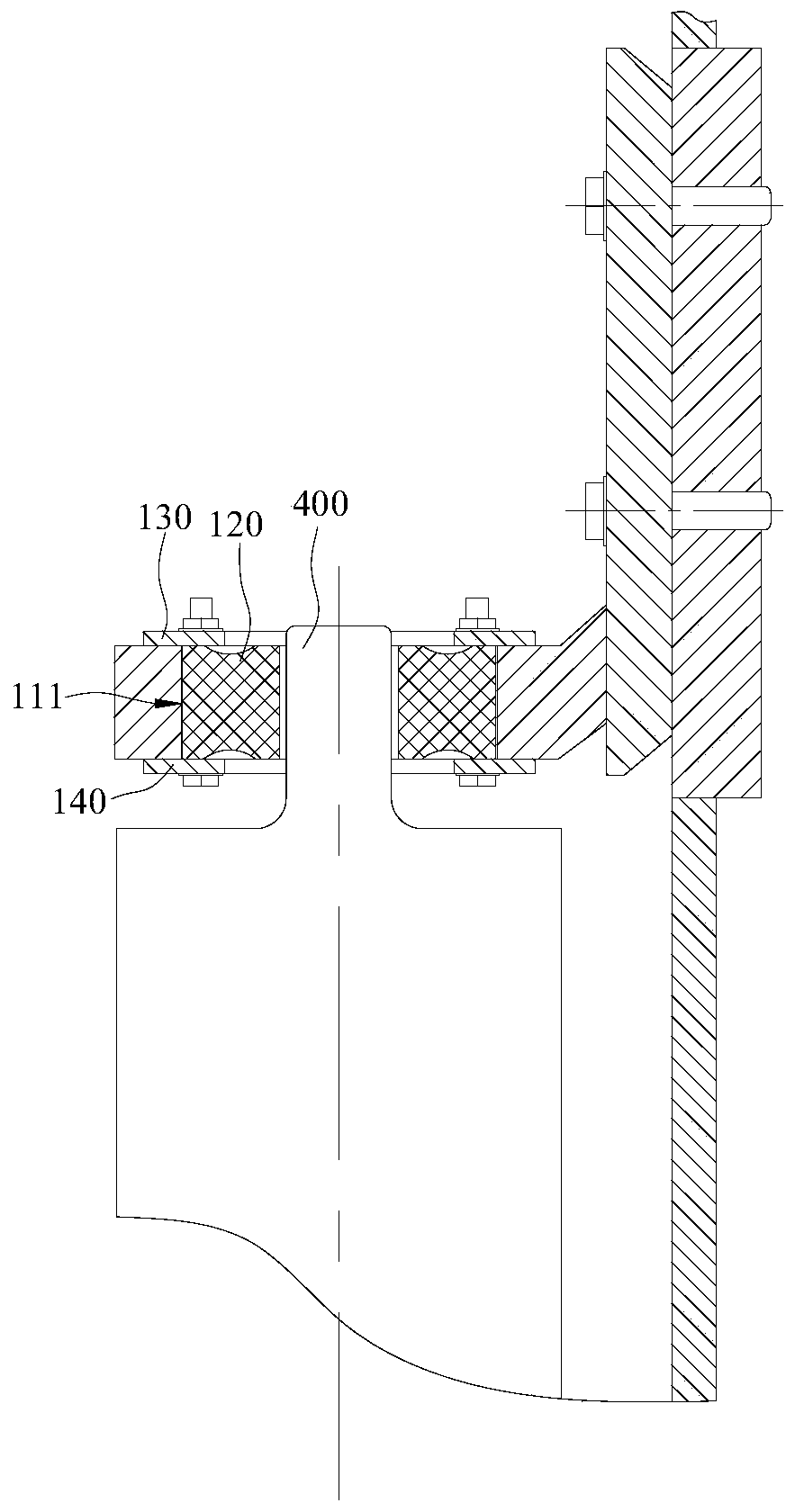

[0056] Embodiment 2 refers to image 3 as shown,

[0057] The implementation principle and technical effect of the flexible connection device at the tail end of the pressurized oil cylinder provided by the embodiment of the present invention are basically the same as those of Embodiment 1. For a brief description, reference can be made to Embodiment 1 for what is not mentioned in this embodiment. Corresponding content.

[0058] This embodiment provides a flexible connection device at the tail end of the pressurized oil cylinder, and the difference from Embodiment 1 is that the flexible connection device at the tail end of the pressurized oil cylinder not only includes the first limiting member 130 but also the second limiting member 140 . The structure of the second limiting member 140 is the same as that of the first limiting member 130 , and the second limiting member 140 also has a through hole whose diameter is larger than the outer diameter of the connecting rod 400 and ...

Embodiment 3

[0059] Embodiment 3 refers to Figure 4 as shown,

[0060] The implementation principle and technical effect of the flexible connection device at the tail end of the pressurized cylinder provided by the embodiment of the present invention are basically the same as those of Embodiment 1. For a brief description, reference can be made to Embodiment 1 for the parts not mentioned in this embodiment. Corresponding content.

[0061]This embodiment provides a flexible connection device at the tail end of a pressurized oil cylinder. The difference from Embodiment 1 is that the first stopper 130 is omitted, and the first hole segment 111a and the second hole segment 111b of the installation hole 111 are In exchange, the first hole segment 111 a with a larger hole diameter is closer to the pressurized oil cylinder 300 . In this embodiment, the shape of the shock-absorbing elastic member 120 is also different from that of Embodiment 1. In this embodiment, the shape of the shock-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com