Rice husking device

A technology for rice husk and rice, which is applied in the direction of grain husking, grain processing, and grain pod removal, etc. It can solve the problems of low processing efficiency, paddy blockage, complex structure, etc., and achieve the effects of reasonable design, improved service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

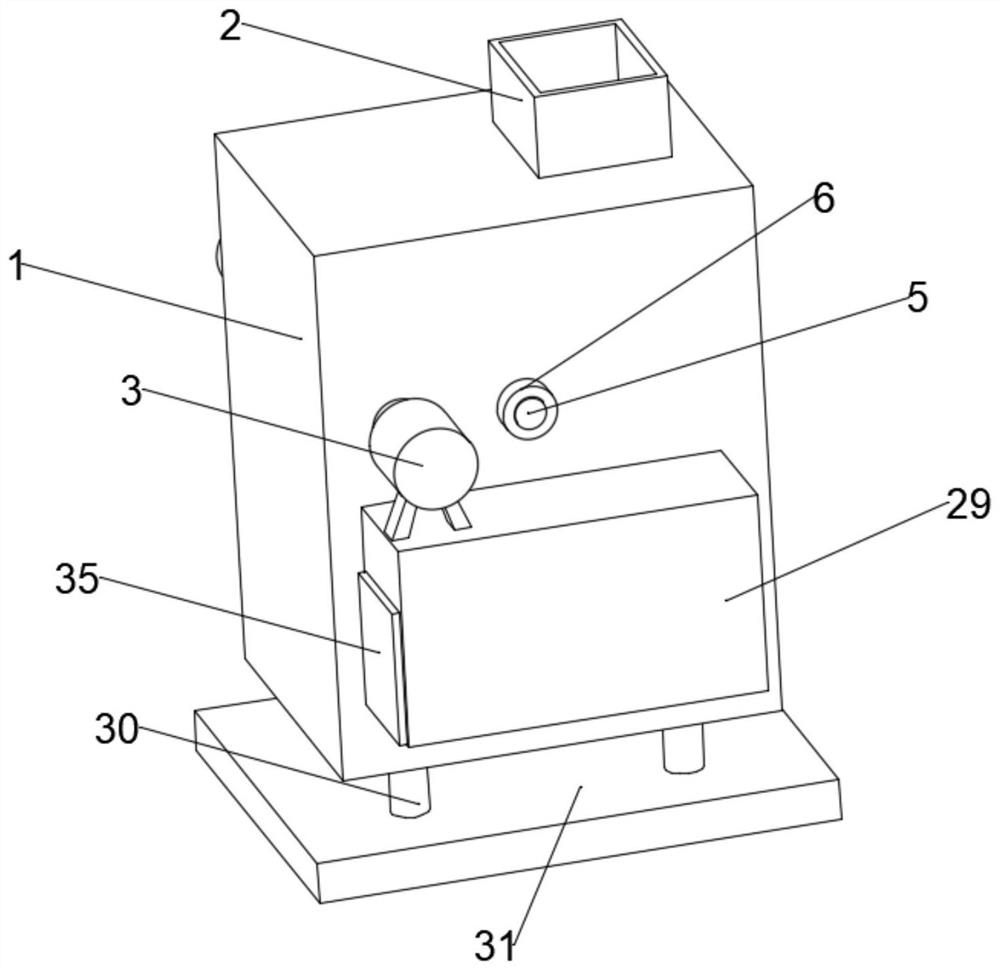

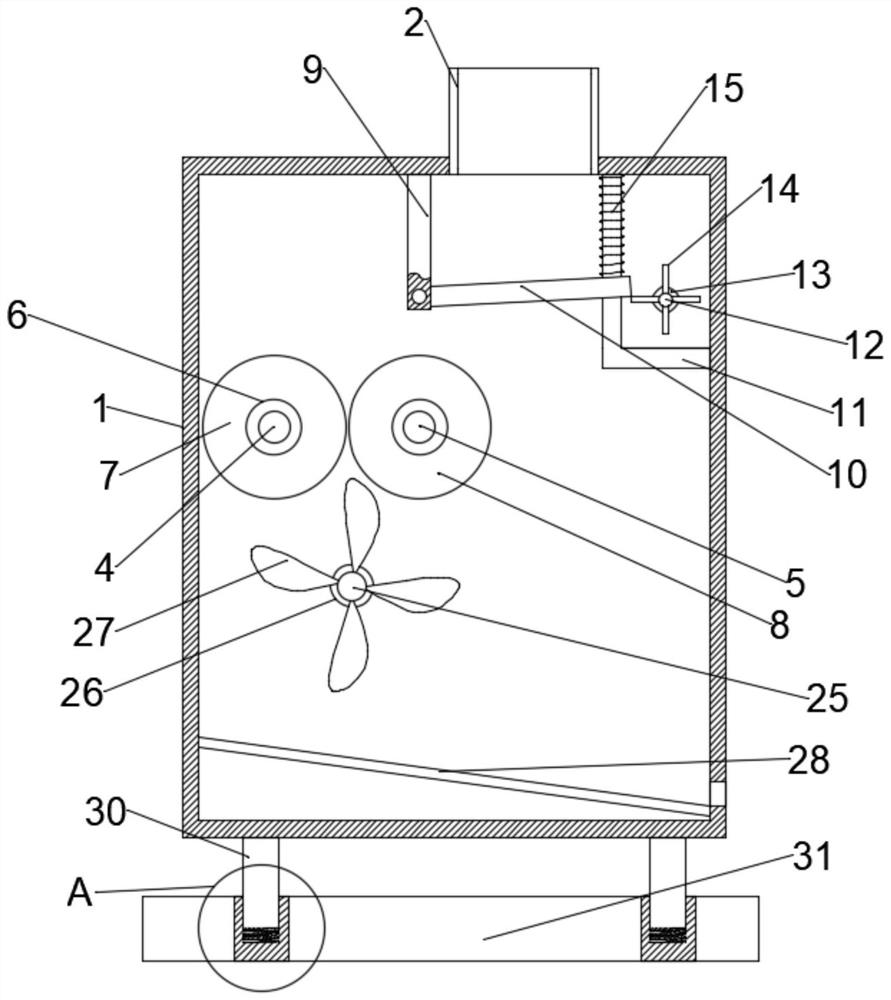

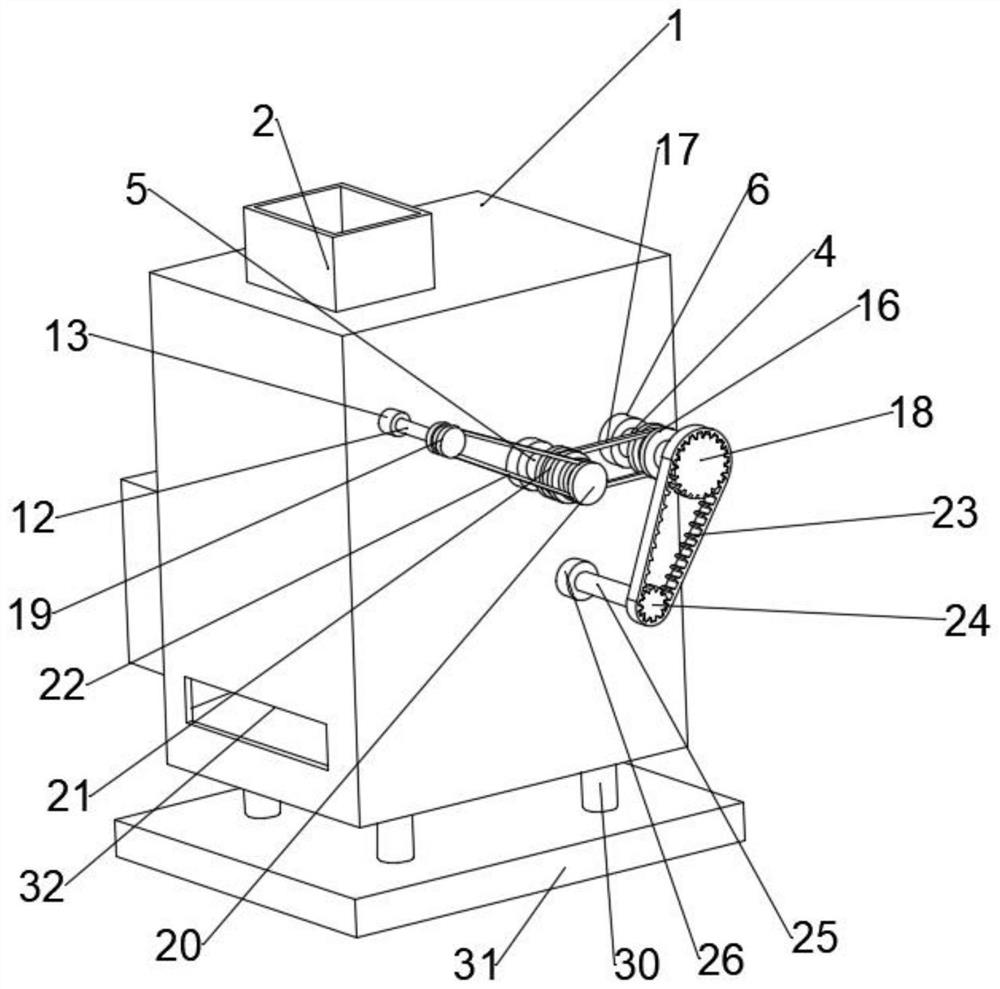

[0025] combine Figure 1-3 , a paddy shelling device, comprising a base 31, a support column 30 and a housing 1, the housing 1 is fixed above the base 31 through the support column 30, and the inside of the housing 1 is provided with a first guide plate 10, so The left end of the first guide plate 10 is rotatably connected to the vertical plate 9 fixed above the inside of the housing 1, and the right end of the first guide plate 10 passes through the L-shaped connecting plate 11 fixed above the inside of the housing 1 and the first spring 15. Fixedly connected, the first rubber roller 7 and the second rubber roller 8 are arranged on the lower left side of the first guide plate 10, and the first rotating shaft 4 is arranged at both ends of the first rubber roller 7, and the first rotating shaft 4 The first bearing seat 6 is rotatably connected with the housing 1, the two ends of the second rubber roller 8 are provided with a second rotating shaft 5, and the second rotating shaf...

Embodiment 2

[0035] combine figure 2 with Figure 4 , a paddy hulling device, this embodiment further limits the present invention on the basis of embodiment 1.

[0036] The upper part of the base 31 is provided with a plurality of circular slots 33 , the second springs 34 are fixed in the circular slots 33 , and the upper ends of the second springs 34 are connected to the lower ends of the support columns 30 .

[0037] Specifically, by disposing the second spring 34 between the support column 30 and the base 31, the vibration generated by the casing 1 can be effectively absorbed and the service life of the device can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com