Rotary locking type hydraulic damping sucking disk device

A hydraulic shock absorption and locking technology, which is applied in the direction of spring/shock absorber, non-rotational vibration suppression, suction cup, etc., can solve the problems of low suction cup adsorption capacity, laborious operation of suction cup, uneven force, etc., to achieve simple operation, The effect of reducing the operation process and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

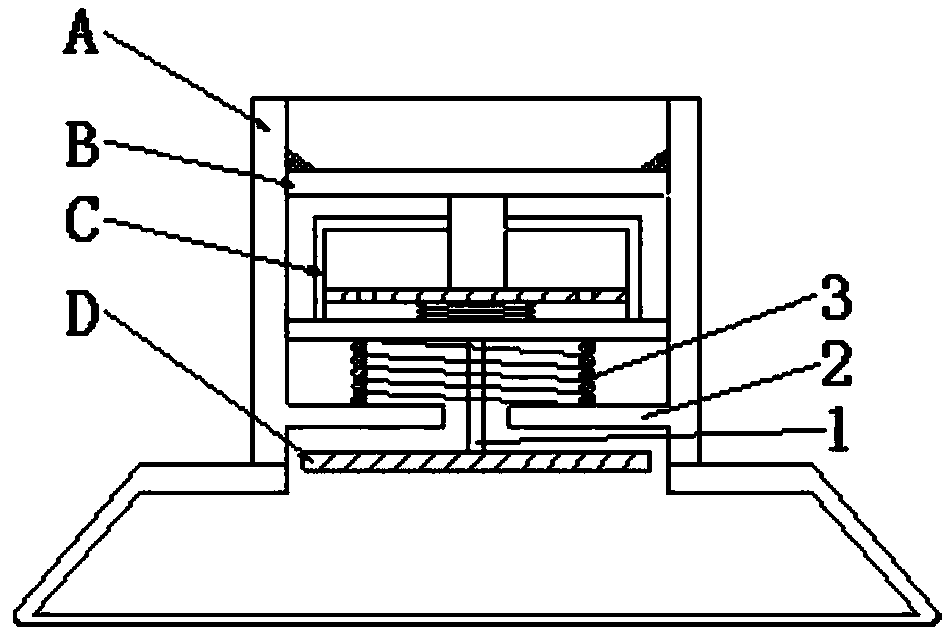

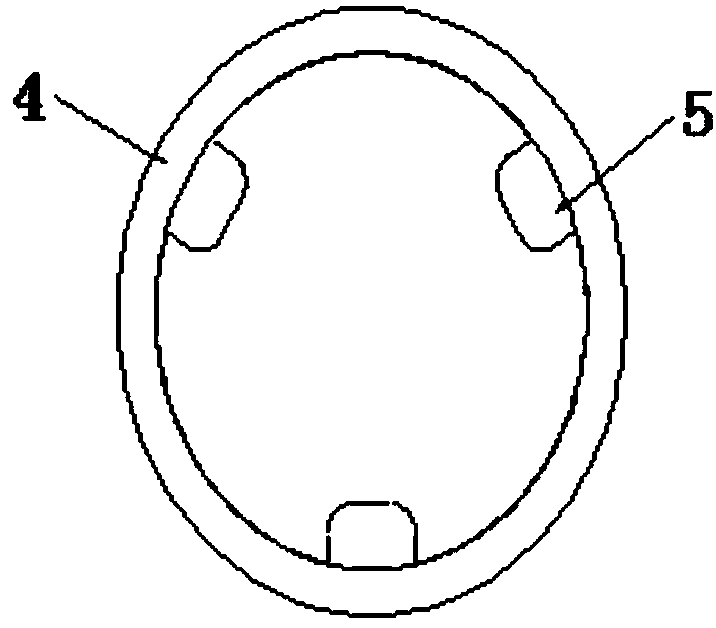

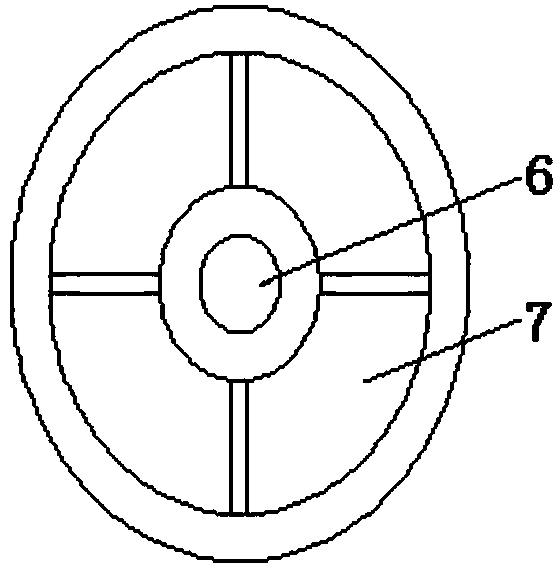

[0041] Such as figure 1 As shown, the present invention is composed of a suction cup assembly A, a push knob B, a hydraulic assembly C, a sealing assembly D and a spring I3, wherein the pressing knob B, the hydraulic assembly C, the spring I3 and the sealing assembly D are in the hollow cylinder 4 of the suction cup assembly A Arranged from top to bottom, press the cylindrical surface of the tappet 17 in the knob B to slide and connect with the center hole II18 on the cover of the cylinder body 16 in the hydraulic assembly C and slide and seal with the center hole II18, the lower end of the tappet 17 is connected to the hydraulic assembly C The center above the buffer plate 13 is affixed.

[0042] The outer edge of the three flanges 10 of the pressure plate 9 in the press knob B is slidingly connected with the inner wall of the hollow cylinder 4 of the suction cup assembly A, and the three flanges 10 of the pressure plate 9 in the press knob B are covered by the hollow cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com