Oral liquid bottle drying method and drying machine

A drying method and technology of oral liquid, applied in the direction of drying machine, drying solid material, drying gas arrangement, etc., can solve the problems of increased production cost and uncontinuous production, and achieve saving of construction cost, low cost and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

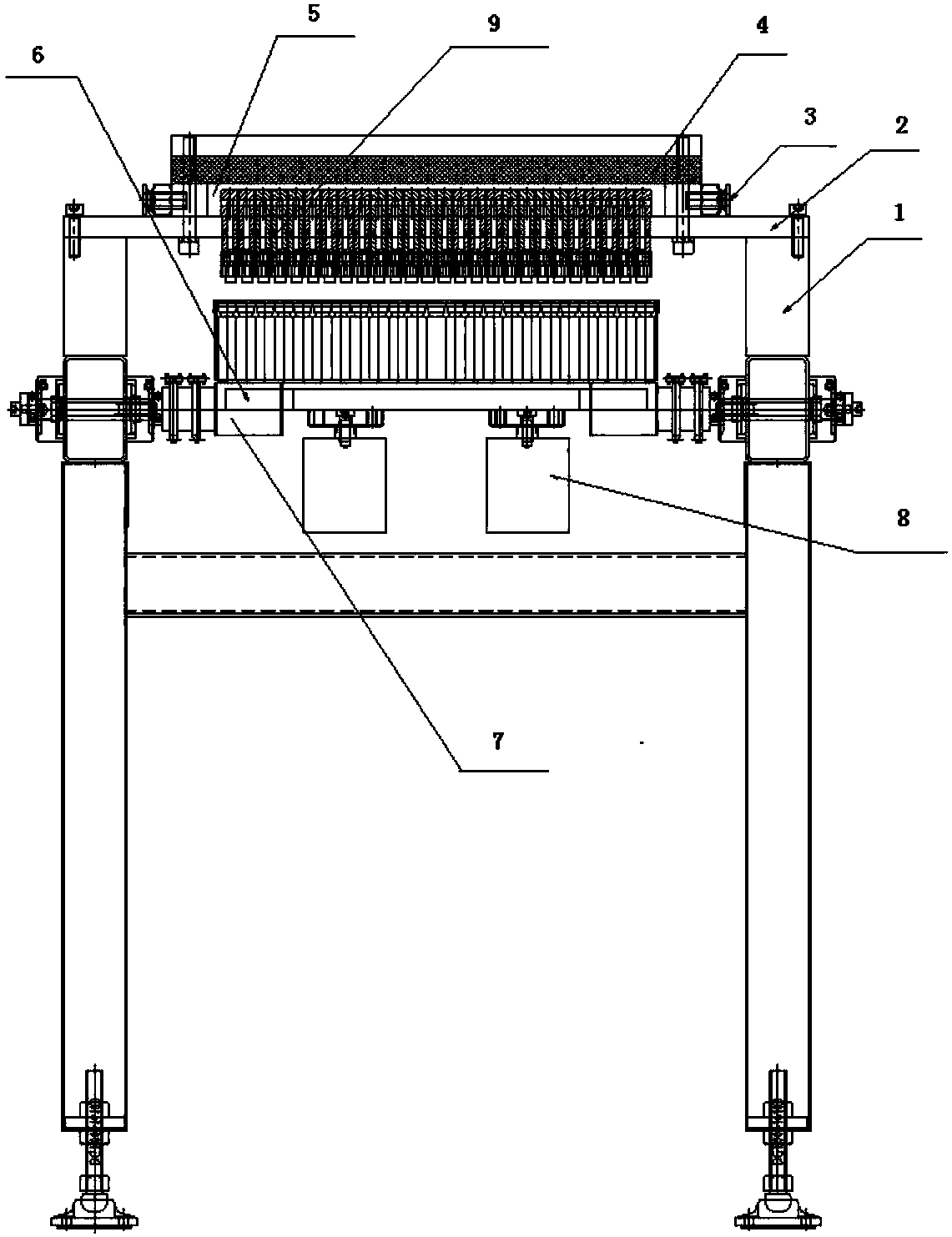

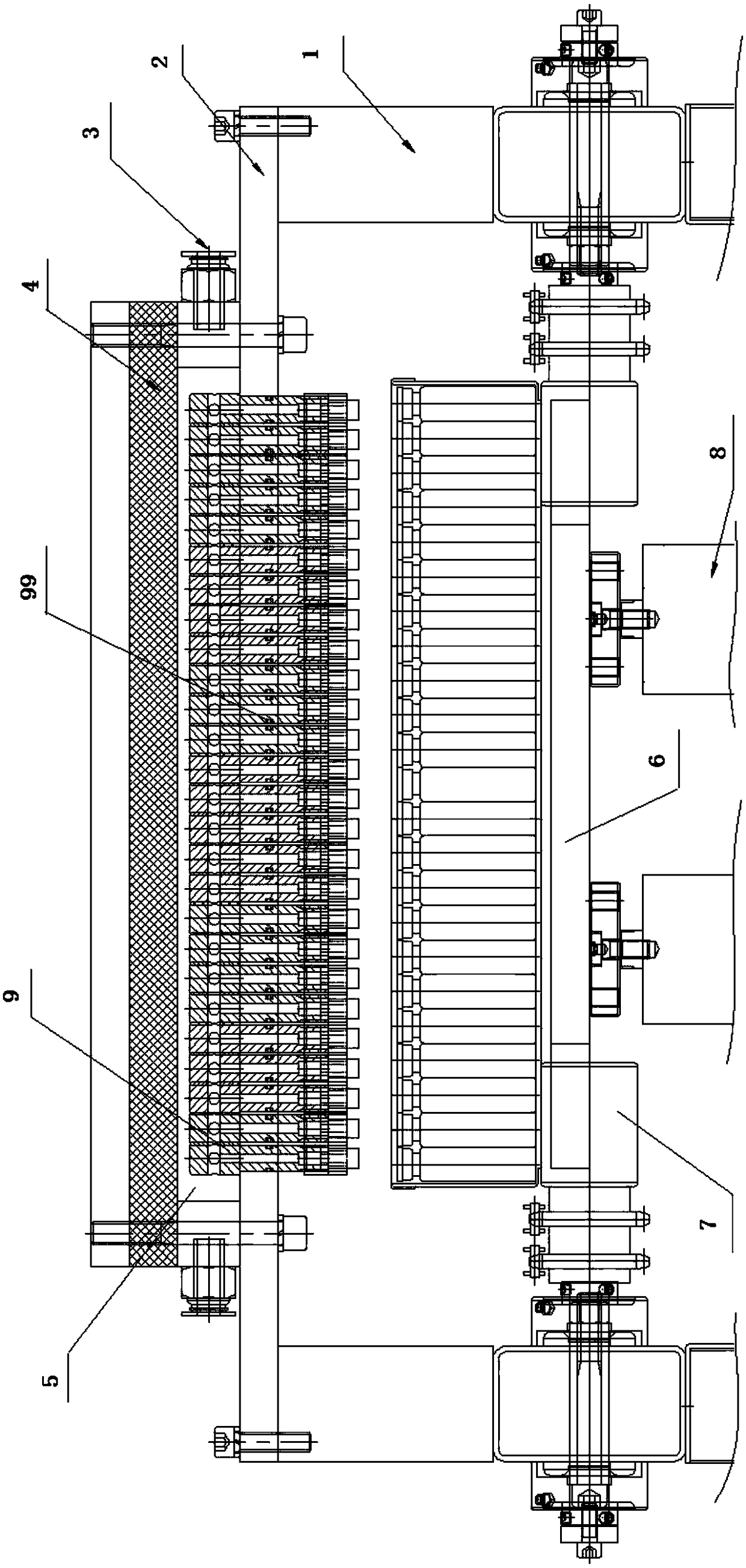

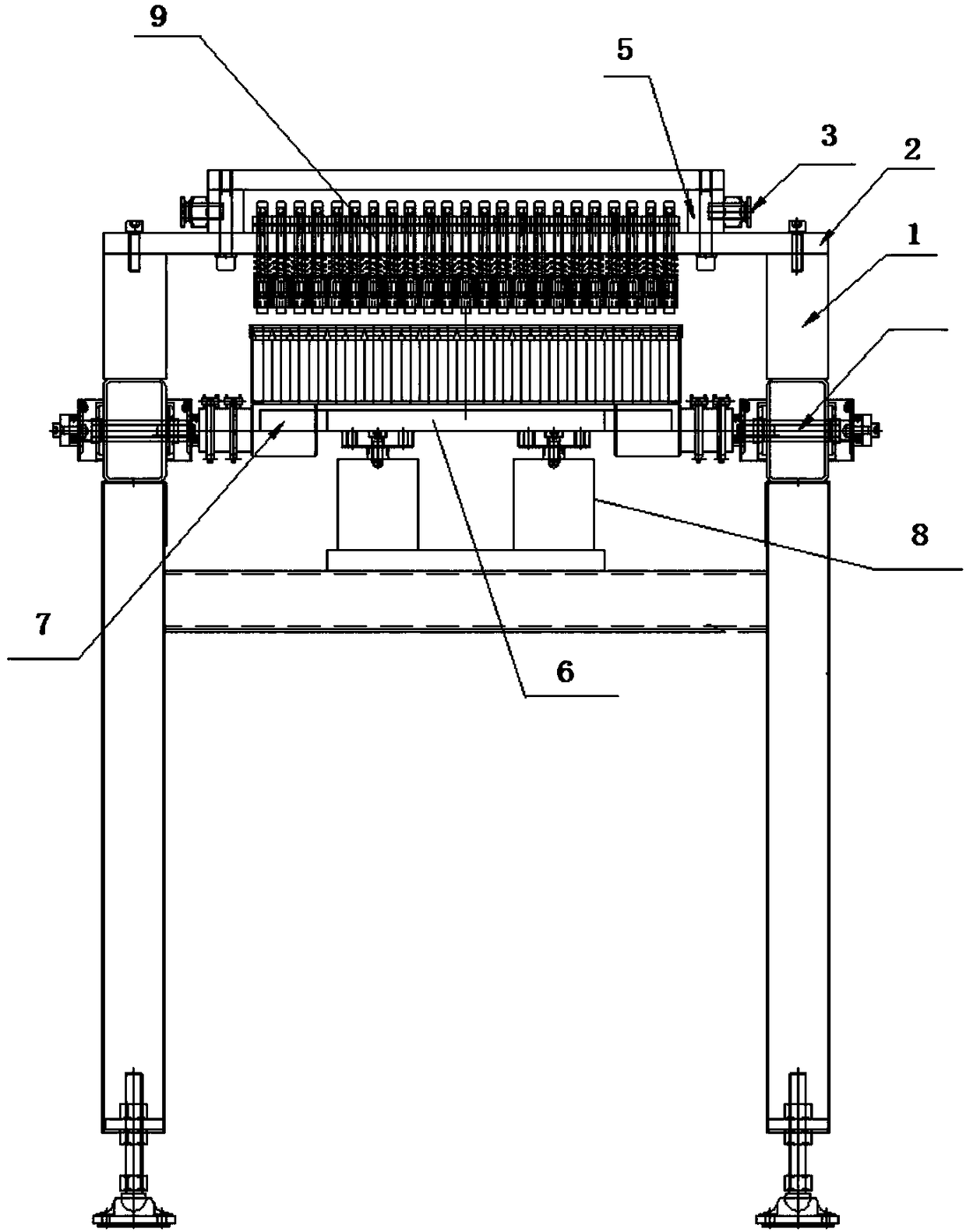

Image

Examples

Embodiment 1

[0041] Example 1, a drying method for an oral liquid bottle: After the oral liquid bottle is sprayed and sterilized, it is dried by a method including extruding the aluminum-plastic cap to drain water.

Embodiment 2

[0042] Embodiment 2, a drying method of oral liquid bottle: after the oral liquid bottle is sprayed and sterilized, adopt the method comprising extruding the aluminum-plastic cap to drain water and place the oral liquid bottle to be dried in a water spinner for centrifugation Tumble drying method. The drainage process of the extruded aluminum-plastic cover is carried out before or after the centrifugation drying process.

Embodiment 3

[0043] Example 3, in the drying method of the oral liquid bottle described in Example 1 or 2: a drying process is also provided after the extruding aluminum-plastic cap drainage process and the centrifugal spin-drying drying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com