Spatial storage of components between processing positions

A component and station technology, applied in the field of manufacturing electronic components, to achieve the effect of shortening the distance and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

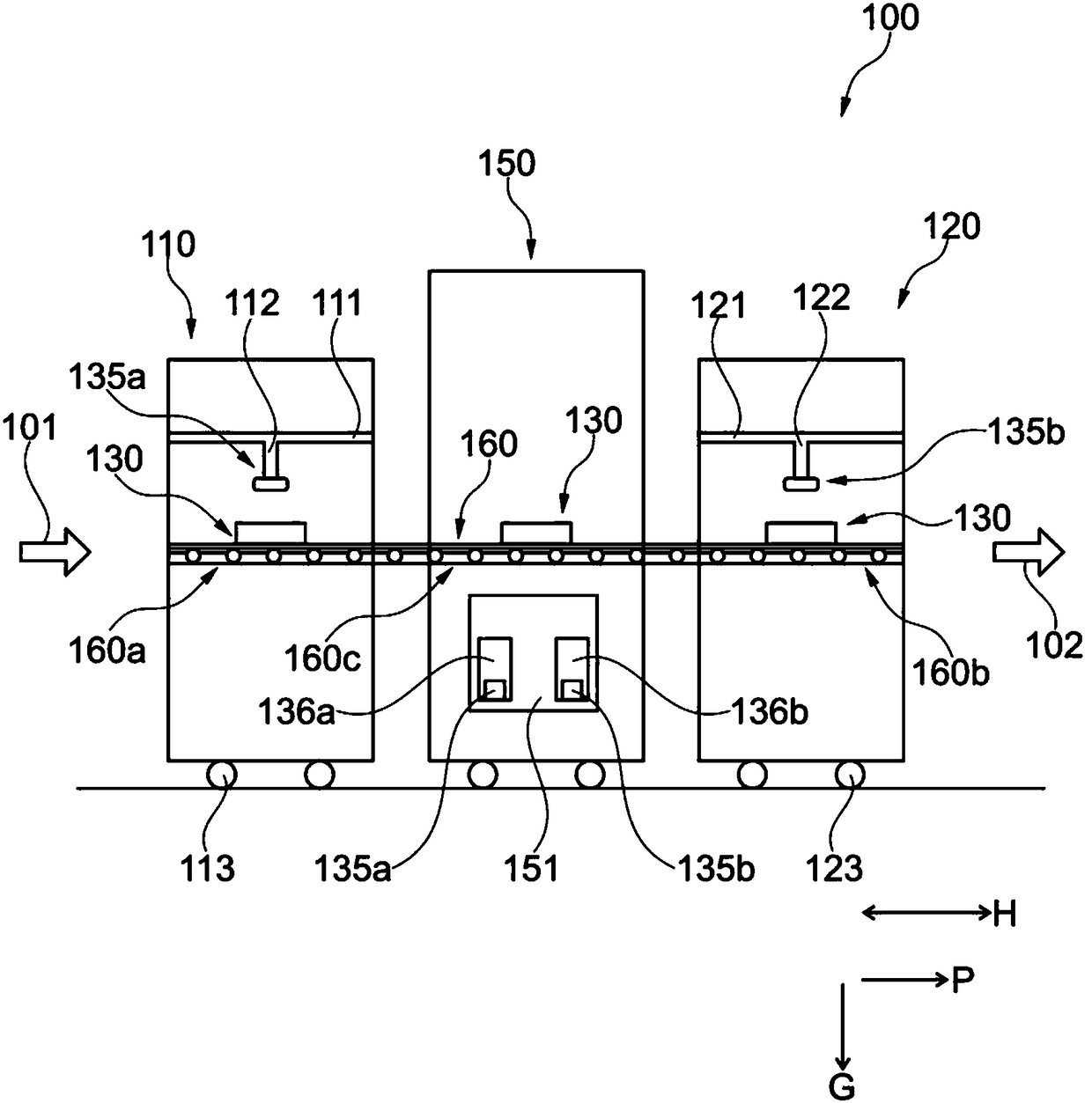

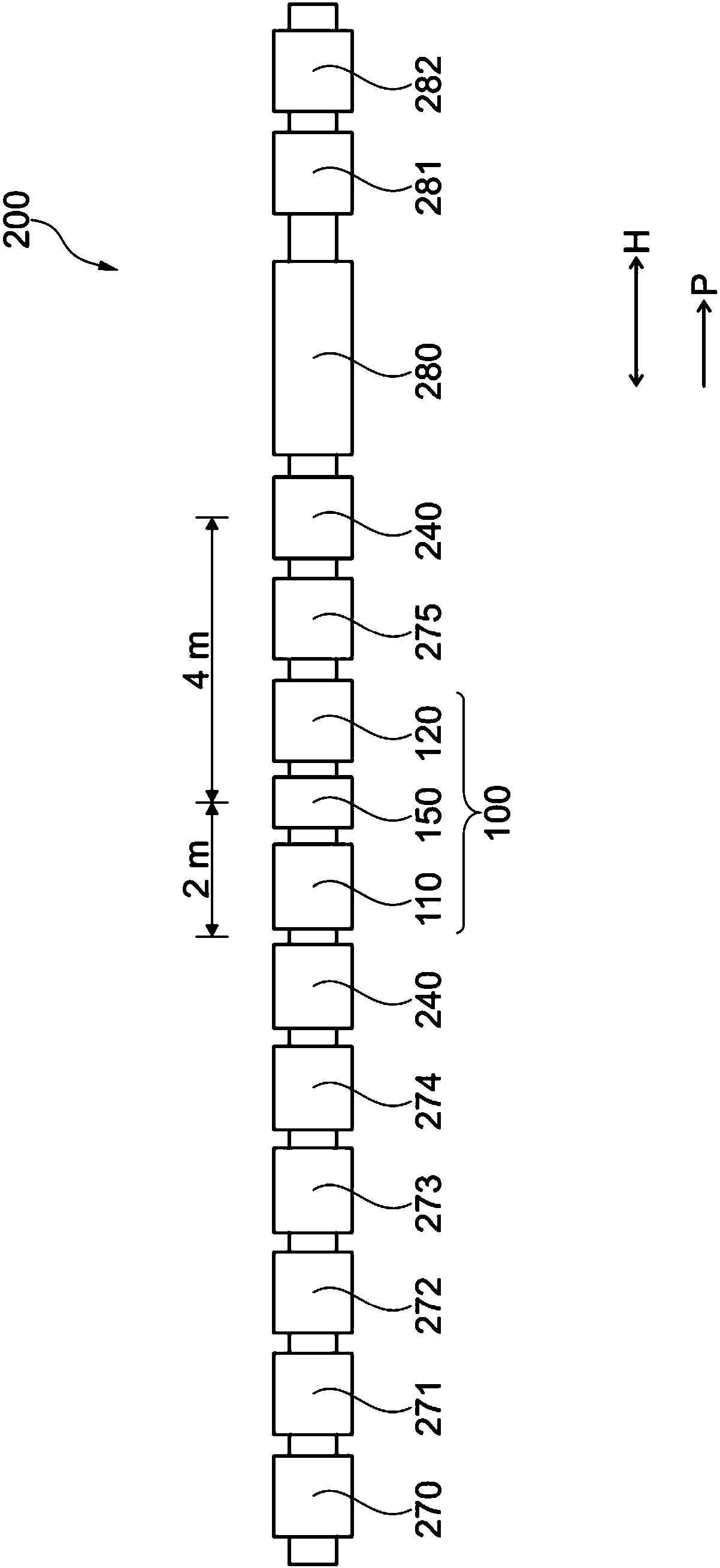

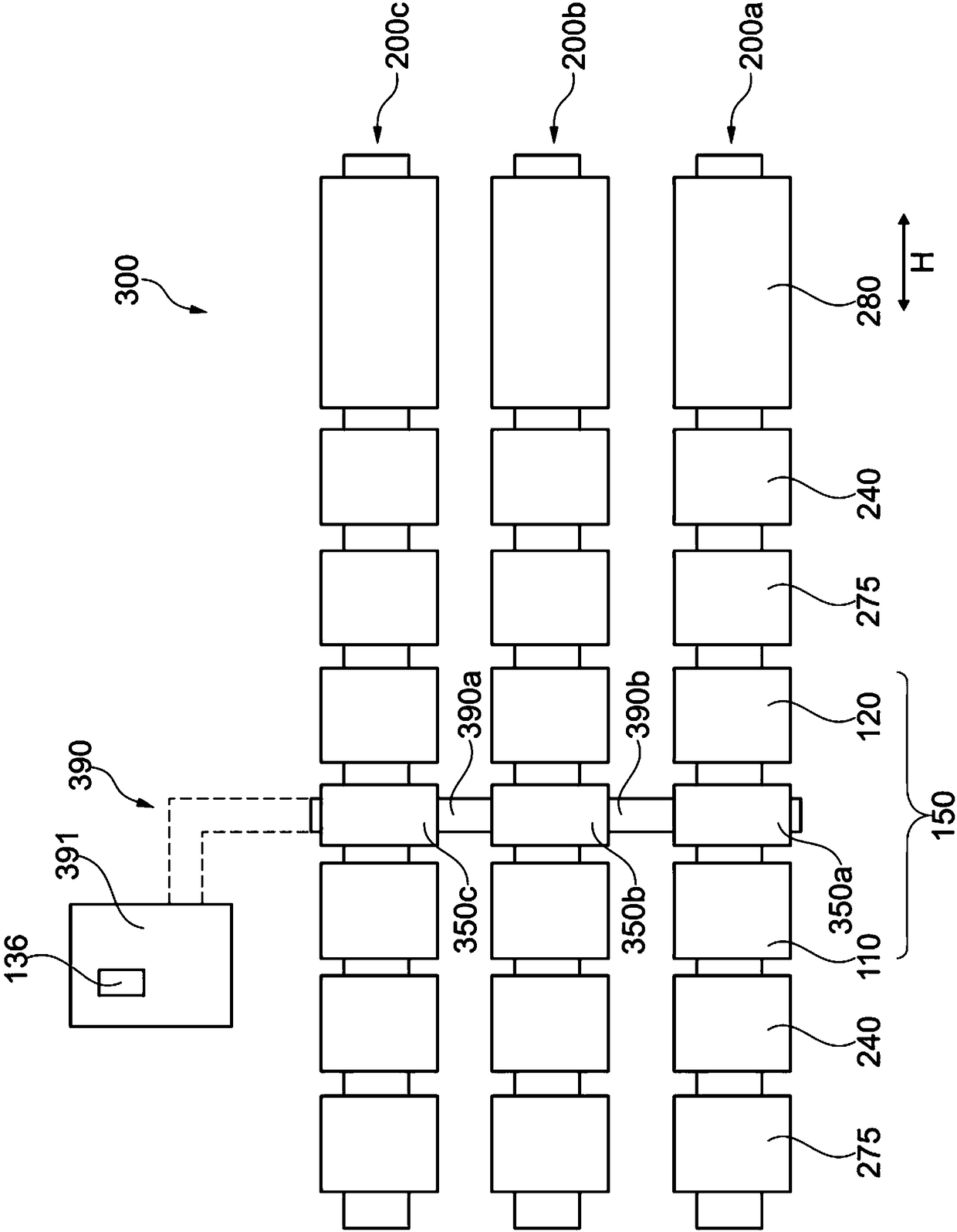

[0117] Identical or similar parts are denoted by the same reference numerals in the figures.

[0118] According to one embodiment, logistic costs in supplying materials currently account for a major portion of operating production lines and production equipment. Material supply is often solved in various ways because there are not many suitable solutions. On the basis of this document, this logistical outlay is significantly reduced by considerably shortening the paths on the production line or production plant.

[0119] According to a further exemplary embodiment of the invention, the basic idea consists in combining several functions and thus integrating the component memory directly in the production line. In this embodiment, a conveyor device, in particular a conveyor belt, is combined with a component storage. There is a module here which can store and transfer the material, but which also enables the flow of the component carriers to be assembled. The module can be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com