Production method of fermented avena sativa-phellinus igniarius grain powder rich in phellinus flavone

The technology of a yellow grain fungus powder and a production method, which is applied in the field of active substance production, can solve the problems of not being able to obtain artificially cultivated authentic Phellinus fungus fruiting bodies, and achieve the effects of improved antioxidant capacity, increased flavonoid yield, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

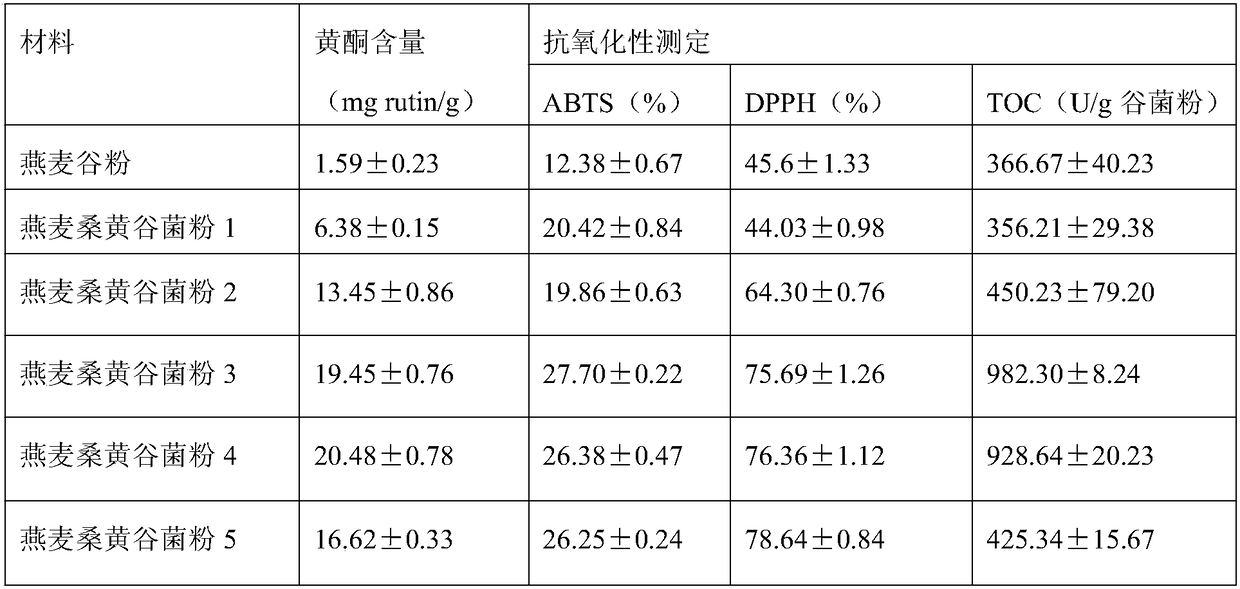

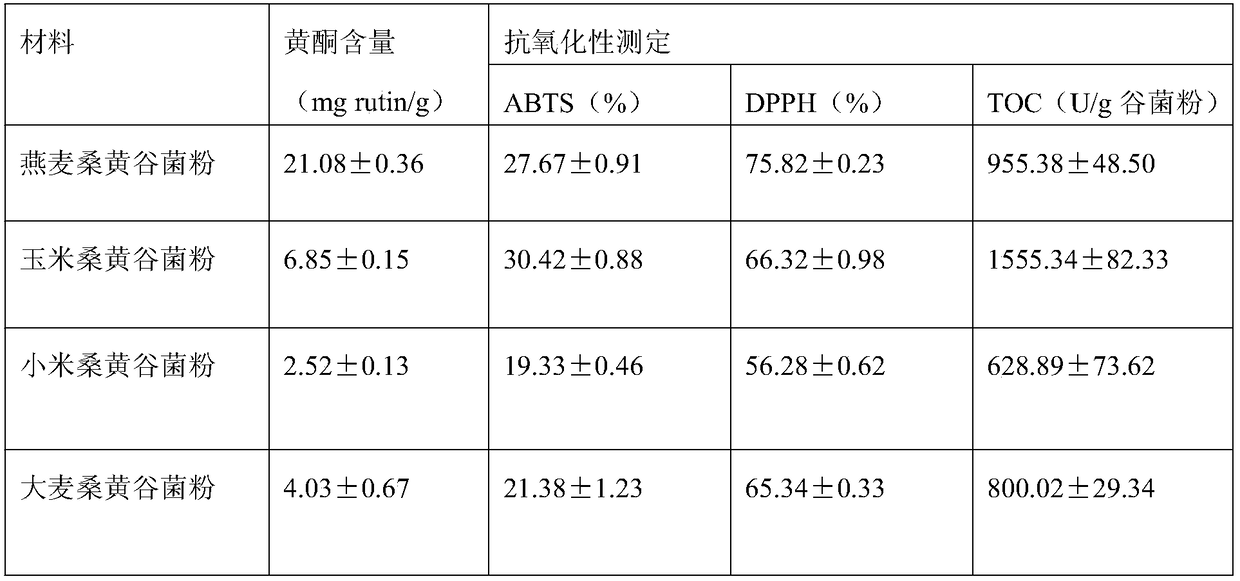

Examples

Embodiment 1

[0020] A production method of oat Phellinus Phellinus cereal powder rich in Phellinus flavonoids, comprising the steps of:

[0021] (1) Cultivation of Phellinus Phellinus liquid fermentation strain: inoculate the activated mother species of Phellinus slant on the PDA medium, activate the cultivation, the cultivation temperature is 25°C, and the cultivation time is 10 days to obtain Phellinus bacterium block, take the edge cross section Inoculate the Phellinus bacterium block with a diameter of 1cm into a culture bottle equipped with 50ml PD liquid medium and place the culture bottle in a shaker for constant temperature fermentation culture. The rotation frequency of the shaker is 100rpm, and the culture temperature is 25°C. The time is 12 days, and the liquid fermentation strain of Phellinus Phellinus is obtained;

[0022] (2) Cultivation of oat solid Phellinus mycelium: the Phellinus liquid fermentation strain is broken with a homogenizer, and every broken 3s is left standing...

Embodiment 2

[0029] Same as Example 1, the difference is that in the step (2), the solid oat Phellinus fungus is cultivated, and the cultivation time is 11 days, and the oat Phellinus cereal fungus powder 2 is finally obtained.

Embodiment 3

[0031] Same as Example 1, the difference is that in the step (2) the cultivation of the oat solid Phellinus fungus, the cultivation time is 11d, and after the cultivation, the culture bottle is opened and ventilated for 7d, and what is finally obtained is the oat Phellinus Valley Bacteria powder3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com