Finisher vibration vein eliminating method

A technology of skin pass mill and zinc pot, which is applied in the direction of coating, metal material coating process, metal rolling, etc., can solve problems such as rolling mill chattering defects, achieve the reduction of chattering defects, eliminate chattering defects, operation method Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

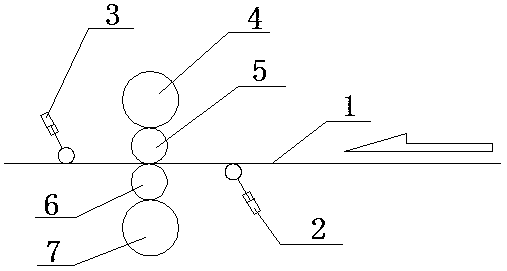

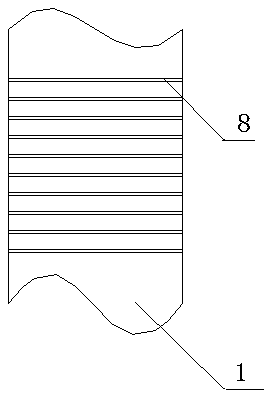

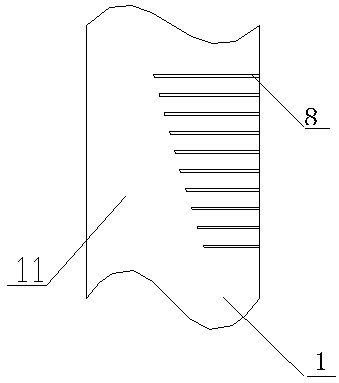

Method used

Image

Examples

Embodiment 1

[0016] 1. In normal production, when switching from CQ steel grade to DDQ steel grade, the 1.0*1250mm strip steel outlet zinc pot has horizontal roll marks, with a spacing of 50-100mm, and the zinc pot stabilizing roller and correction roller bite should be reduced in time Measure 5mm, adjust the gap between the bushing and the bearing bush online to reduce the gap by 1mm, and reduce the vibration of the stabilizing roller and the correcting roller.

[0017] 2. After adjusting the bite amount of the zinc pot stabilizing roll, the defect has not been significantly alleviated. After adjusting the gap between the bushing and bushing of the stabilizing roller and the correcting roller, the defect has been alleviated, but the horizontal roller mark is still unresolved. The bushing and bushing are seriously worn and shaken in the late stage of roller service. Still obvious.

[0018] 3. After the speed of the production line is reduced from 130 m / min to 110 m / min, the defects of roll...

Embodiment 2

[0023] 1. In normal production, when switching from CQ steel grade to DDQ steel grade, the 1.2*1250mm strip steel outlet zinc pot has horizontal roll marks with a spacing of 50-100mm, and the zinc pot stabilizing roll and correction roll bite should be reduced in time Measure 8mm, adjust the gap between the bushing and the bearing bush online to reduce the gap by 3mm, and reduce the vibration of the stabilizing roller and the correcting roller.

[0024] 2. After adjusting the bite amount of the zinc pot stabilizing roll, the defect has not been significantly alleviated. After adjusting the gap between the bushing and bushing of the stabilizing roller and the correcting roller, the defect has been alleviated, but the horizontal roller mark is still unresolved. The bushing and bushing are seriously worn and shaken in the late stage of roller service. Still obvious.

[0025] 3. After the speed of the production line is reduced from 130 m / min to 110 m / min, the defects of roller pr...

Embodiment 3

[0030] 1. In normal production, when switching from CQ steel grade to DDQ steel grade, the 0.78*1250mm strip steel outlet zinc pot has horizontal roll marks with a spacing of 50-100mm, and the zinc pot stabilizing roller and correction roller bite should be reduced in time Measure 10mm, adjust the gap between the bushing and the bearing bush online to reduce the gap by 1mm, and reduce the vibration of the stabilizing roller and the correcting roller.

[0031] 2. After adjusting the bite amount of the zinc pot stabilizing roll, the defect has not been significantly alleviated. After adjusting the gap between the bushing and bushing of the stabilizing roller and the correcting roller, the defect has been alleviated, but the horizontal roller mark is still unresolved. The bushing and bushing are seriously worn and shaken in the late stage of roller service. Still obvious.

[0032] 3. After the speed of the production line is reduced from 130 m / min to 110 m / min, the defects of rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com