Upper mold quick clamping device and application thereof and application method

A clamping device and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of complex clamping structure, low clamping efficiency, poor installation accuracy, etc., to achieve simple clamping and reduce assembly. Errors, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

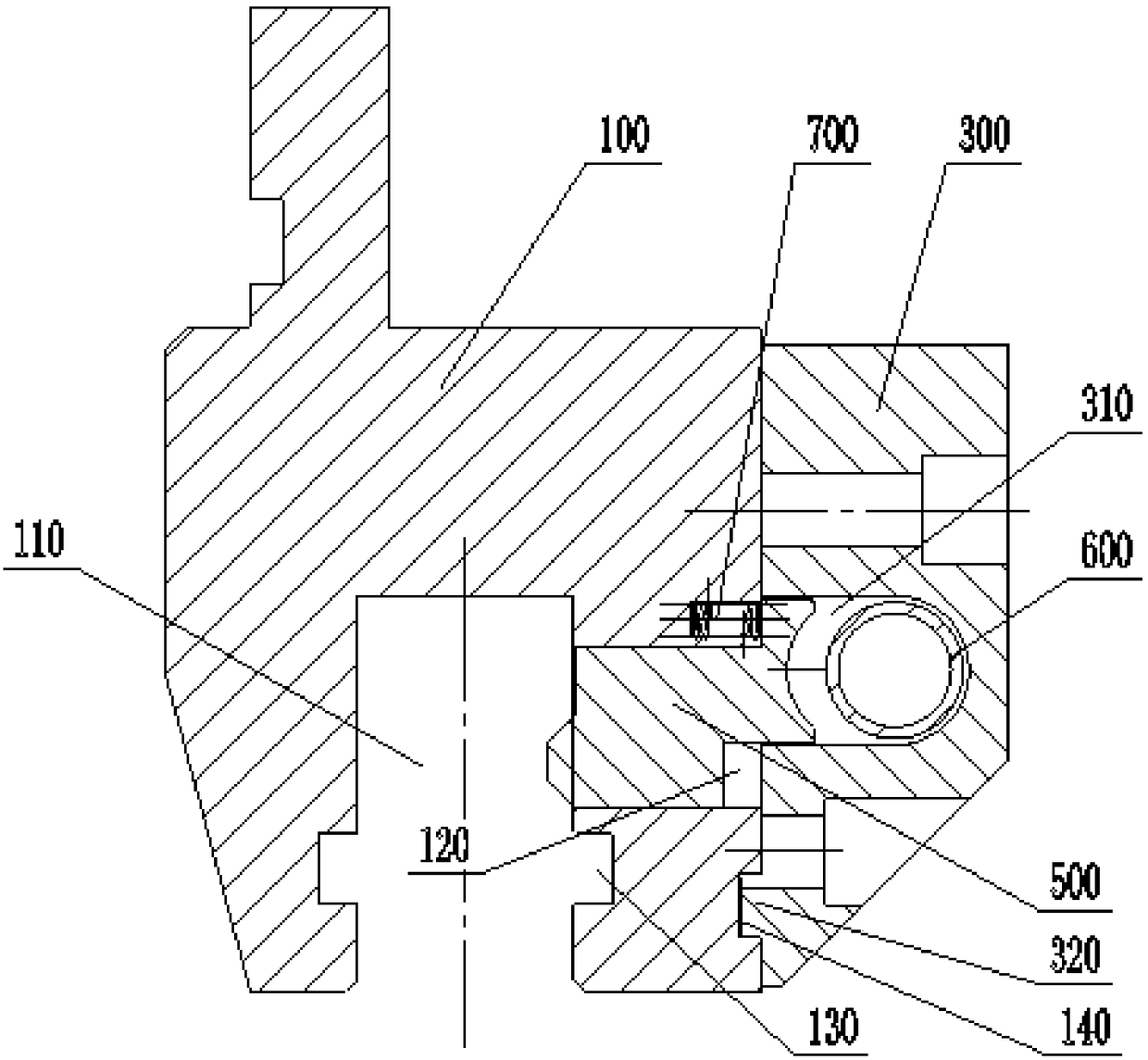

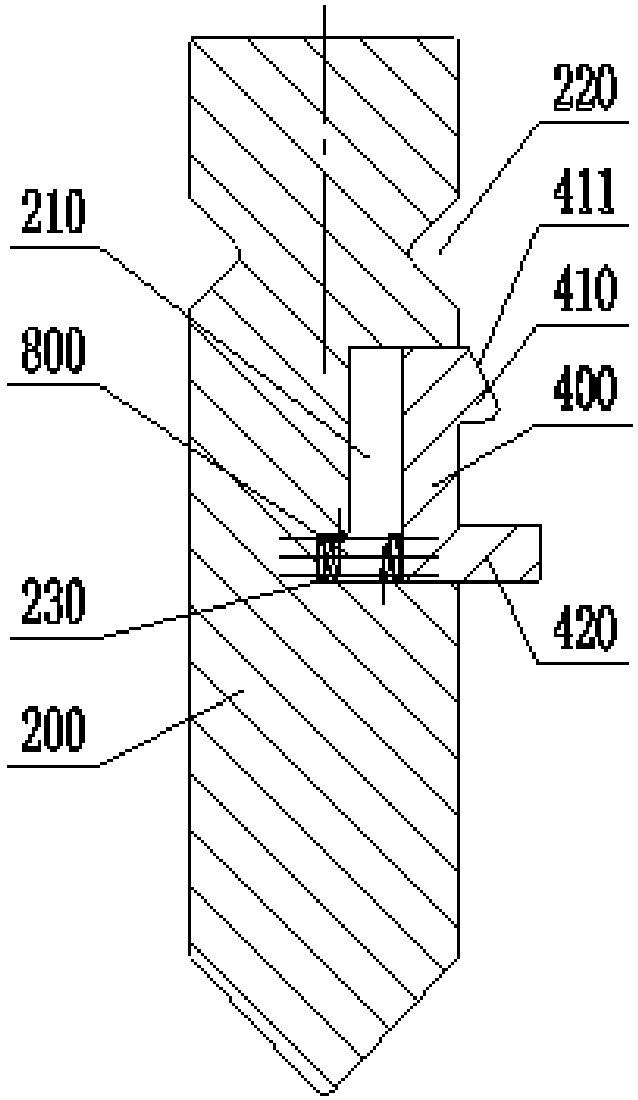

[0059] The quick clamping device for the upper mold of this embodiment is mainly used in production equipment that needs to clamp and replace the mold, such as a bending machine, so as to realize efficient and accurate clamping and replacement of the mold. In this embodiment, taking a bending machine as an example, the structure of the clamping device, as well as its clamping and dismounting methods are described in detail, as follows.

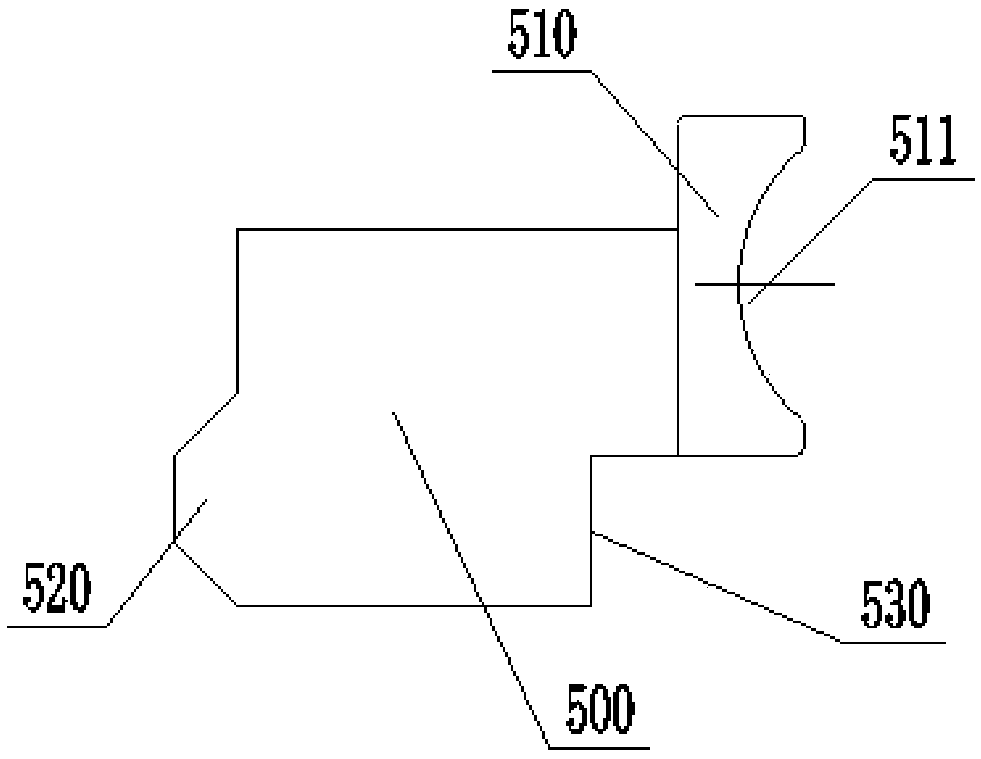

[0060] The upper mold quick clamping device mainly includes an upper mold base 100 and an upper mold 200 used in conjunction with each other, wherein the upper mold base 100 is used to connect the slider of the bending machine, and the upper mold 200 is detachably installed on the upper mold base 100 , used to bend the workpiece on the upper mold. According to the shape of the workpiece of the bending machine, the upper mold 200 used also changes accordingly. The focus of this embodiment is the connection form of the upper mold 200 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com