Universal wrench

A universal wrench and handle technology, applied in the field of universal wrench, can solve the problems of inconvenient to carry, bulky pipe wrench, inconvenient to carry multiple sets of tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 3

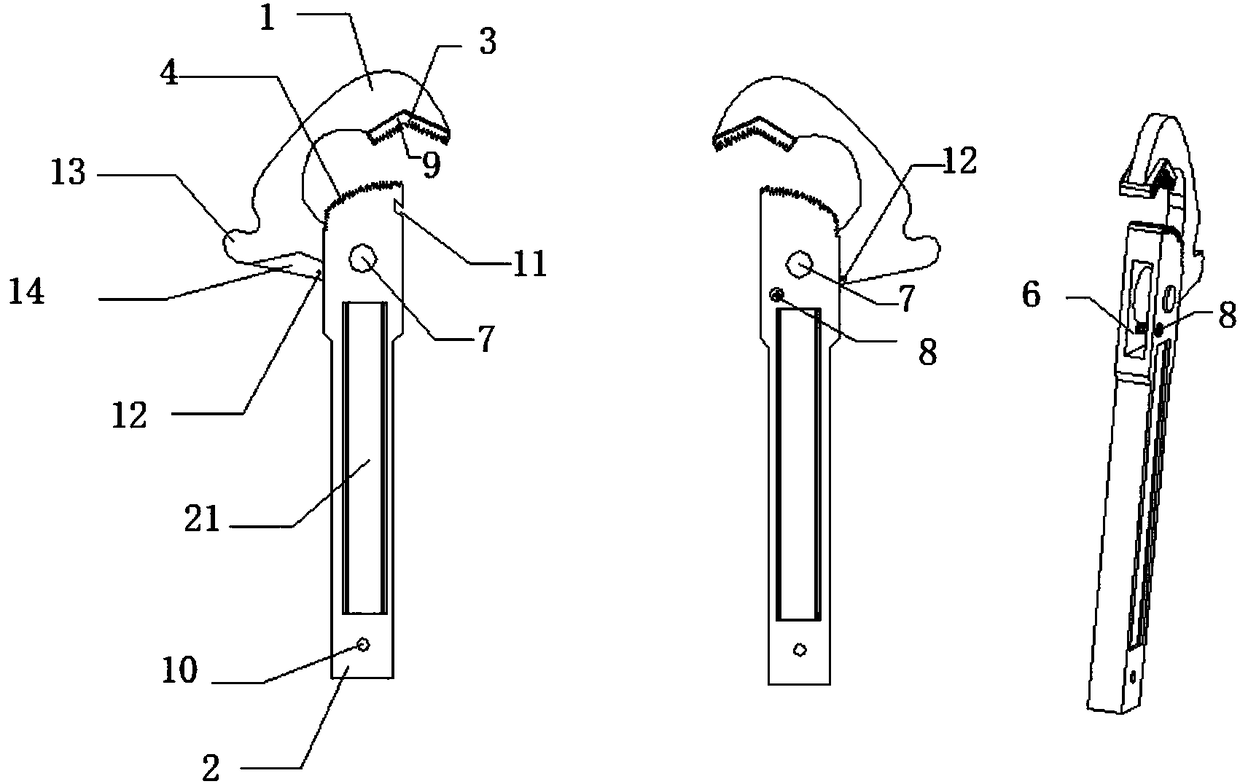

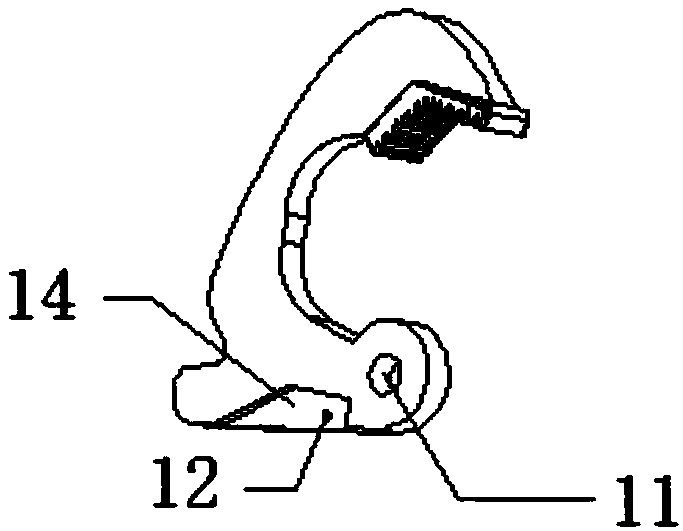

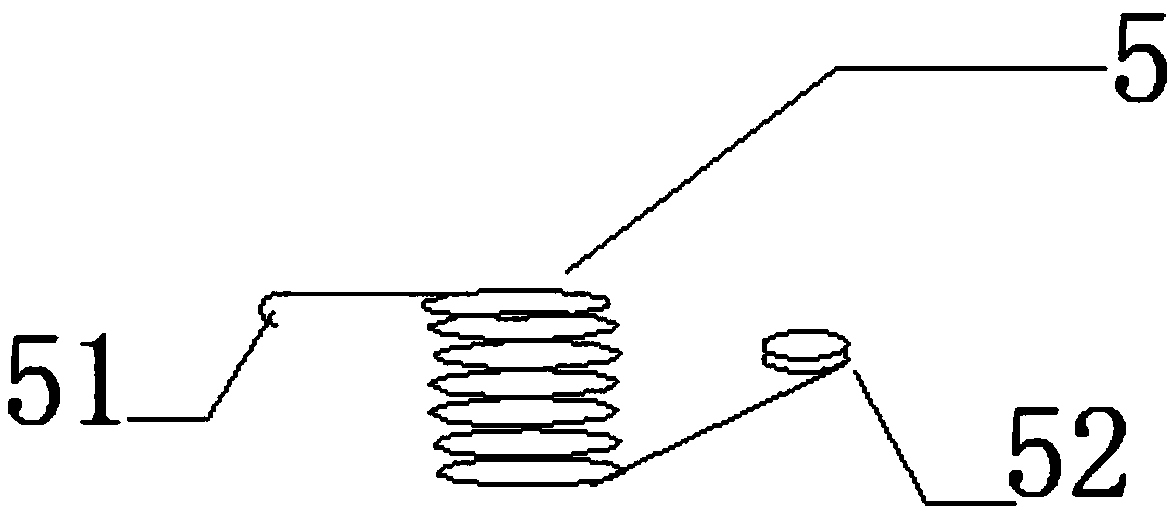

[0033]A universal wrench, comprising: a wrench 1, a handle 2 with a rectangular groove 6 at the upper end, an upper anti-slip tooth 3 integrally formed with the wrench 1, a lower anti-slip tooth 4 integrally formed with the handle 2, and a torsion spring 5. The upper anti-slip teeth 3 are arranged in a V-shaped trajectory, the lower anti-slip teeth 4 are arranged on the front end of the handle 2 and arranged in an arc-shaped trajectory, the rivets 7 pass through the through holes on both sides of the rectangular groove 6 in turn, and the lower end of the wrench 1 is embedded in the rectangular groove. In the connection through hole 11 in 6, the handle 2 and the wrench 1 are relatively fixedly connected to form a whole wrench; the lower end of the wrench 1 is provided with a spring hole 12, and the rectangular groove 6 of the handle 2 is processed on one side plate. A screw 8 is fixed in the screw hole, the bent end 51 of the torsion spring 5 is inserted into the spring hole 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com