Novel PVC calendering machine

A calender, a new type of technology, applied in the field of machinery and equipment, can solve the problems of complex structure and unsatisfactory product quality of the calender, and achieve the effect of simple mechanism, good product quality and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

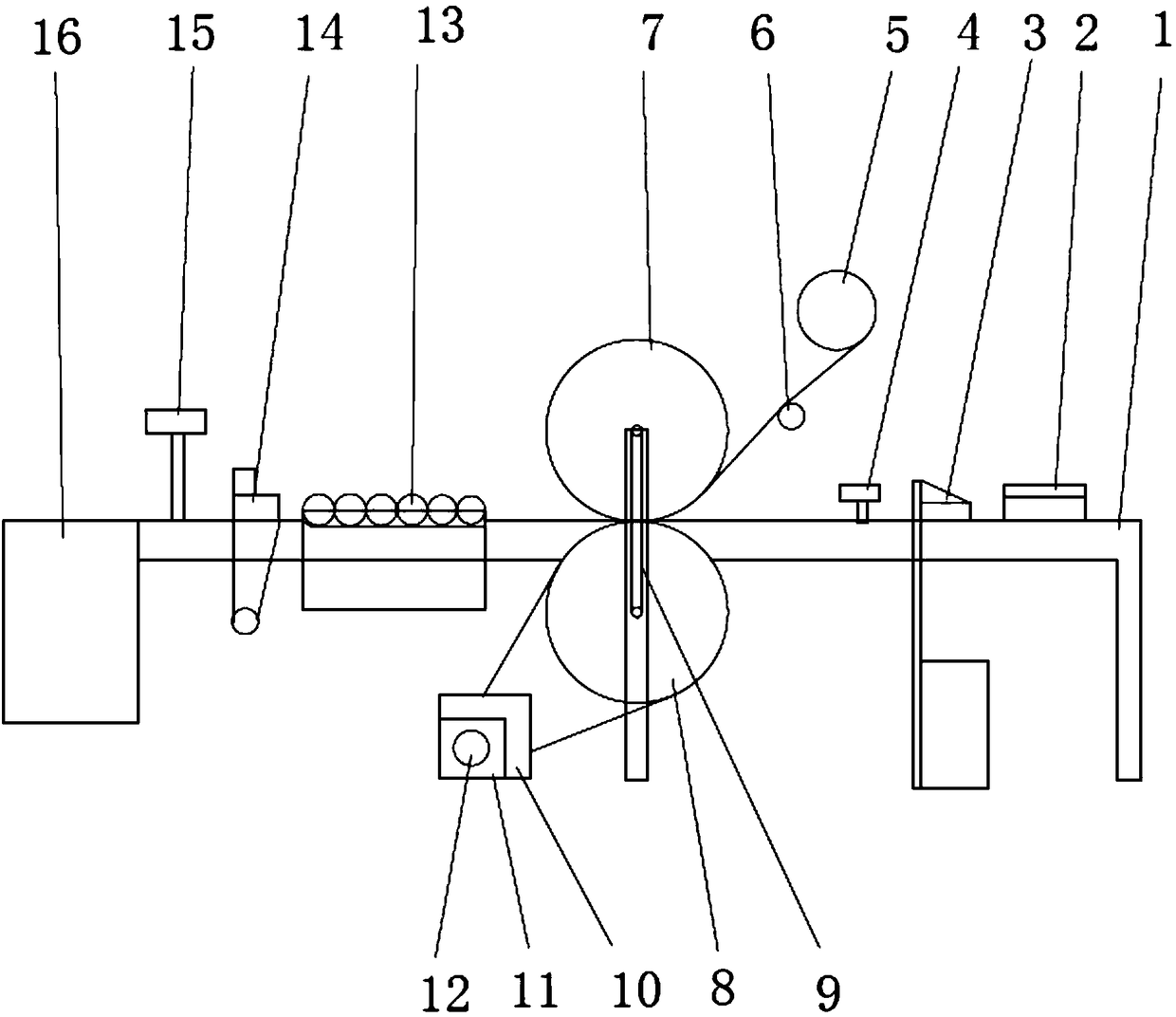

[0016] Such as figure 1 As shown, the present invention provides a novel PVC calender, comprising a carrying platform 1, a dust removal device 2 is provided on one side of the top of the carrying platform 1, a brushing device 3 is provided on one side of the dust removal device 2, and a brushing device 3 is provided on one side of the brushing device 3. There is an electromagnetic temperature control device 4, an unwinding roller 5 is arranged above the electromagnetic temperature control device 4, a guide roller 6 is arranged on the lower left side of the unwind roller 5, and a first calender roller 7 is arranged on one side of the guide roller 6, and the first calender roller 7 There is a second calender roll 8 below, and a distance adjustment device 9 is provided on the outside of the second calender roll 8, and a universal coupling 10 is provided on the lower left side of the second calender roll 8, and a speed reducer is provided on one side of the universal coupling 10 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com