Electric double oil pump system for steering and braking of sanitation vehicle

A technology that uses electric dual- and sanitation vehicles. It is applied in the direction of brake transmission, brakes, and steering mechanisms. It can solve the problems of easy overloading of hydraulic pumps, failure to brake, and high noise of electric pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

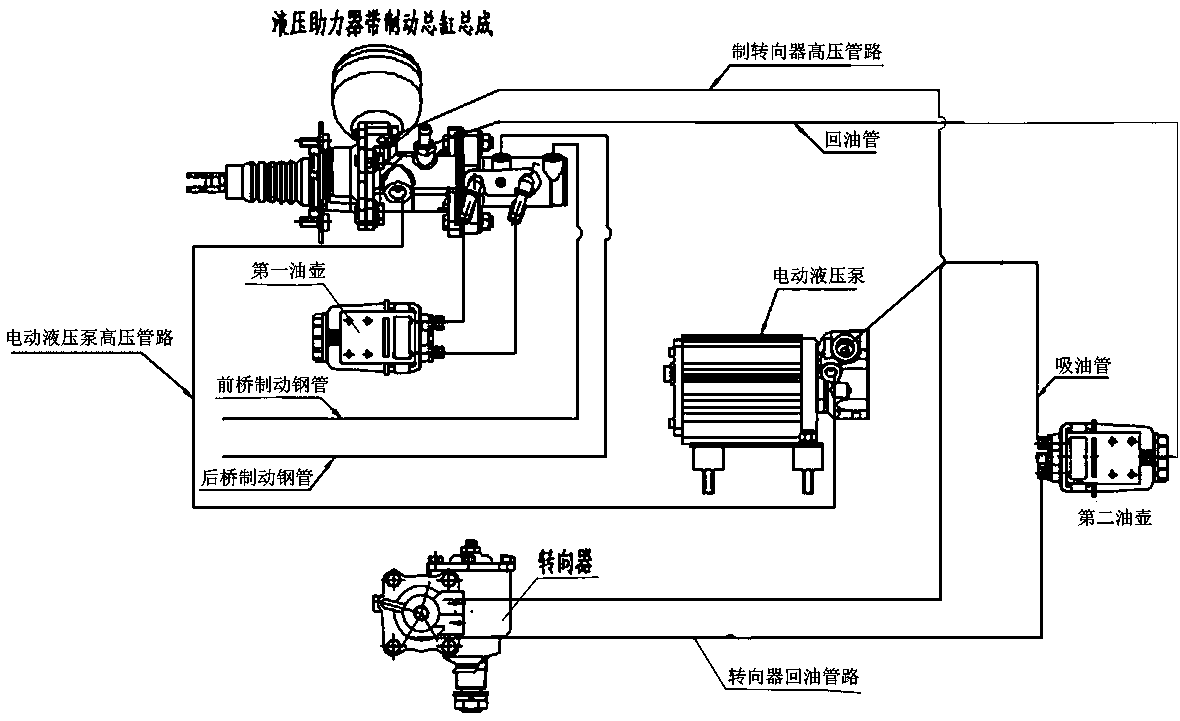

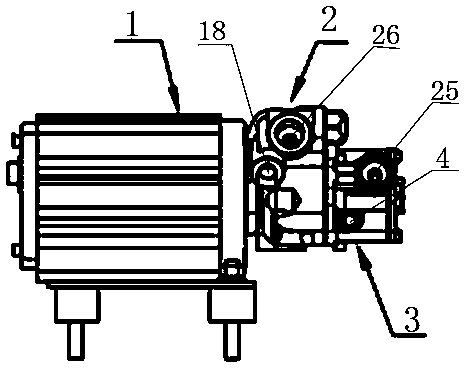

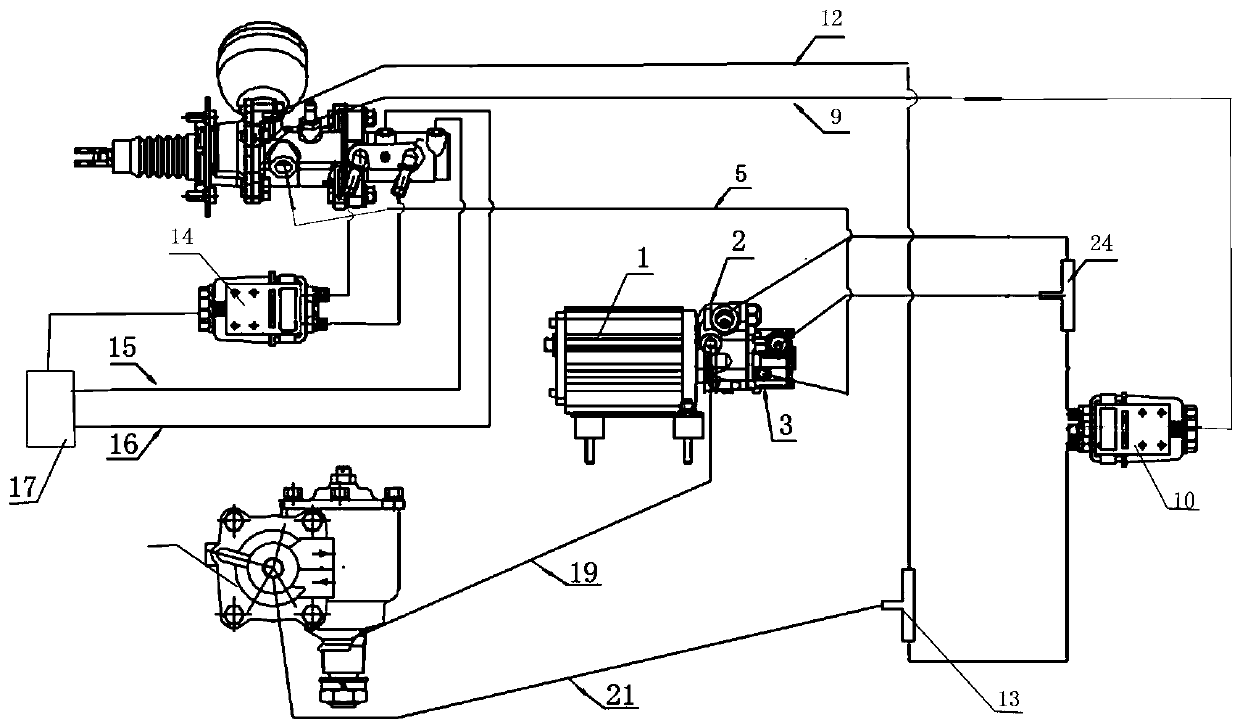

[0018] as attached Figure 2-5 As shown, an electric dual oil pump system for steering and braking of a sanitation vehicle includes a motor 1, the motor 1 is connected with a steering hydraulic pump 2 through a coupling, and the brake hydraulic pump 3 is arranged outside the steering hydraulic pump 2. The steering hydraulic pump The rotor of 2 is coaxial with the rotor of the brake hydraulic pump 3. The hydraulic booster with brake master cylinder assembly 6 includes the hydraulic booster 7 and the brake master cylinder 8. The brake hydraulic pump oil outlet 4 passes through the brake hydraulic pump oil outlet pipe 5 It communicates with the oil inlet 701 of the hydraulic booster, the first oil return port 702 of the hydraulic booster communicates with the first oil inlet 11 of the second oil pot 10 through the first oil return pipe 9, and the second oil return port 703 of the hydraulic booster passes through The second oil return pipe 12 is communicated with the oil inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com