Automatic sorting method and system for storage robot

An automatic sorting system and automatic sorting technology, applied in the field of warehousing and logistics, can solve the problems of difficulty in finding the location of the product, low hit rate of selected products, and low replenishment efficiency, so as to avoid mixed traffic of people and vehicles, The effect of high sorting hit rate and high replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below with reference to the drawings and specific implementations of the specification.

[0071] The present invention is aimed at the low replenishment efficiency, low sorting efficiency, low energy efficiency of robots and system failures caused by the automatic sorting of goods in the existing logistics warehouse robot sorting technology. When it is difficult to replace manually, a storage robot automatic sorting method and sorting system are proposed. Through the sorting method and sorting system, a sorting mode involving both humans and robots can be achieved. When the storage robot system When there is a crash or failure to complete the sorting task, it can be directly switched to the manual sorting mode, and the robot can completely replace the robot to complete the sorting out of the library task.

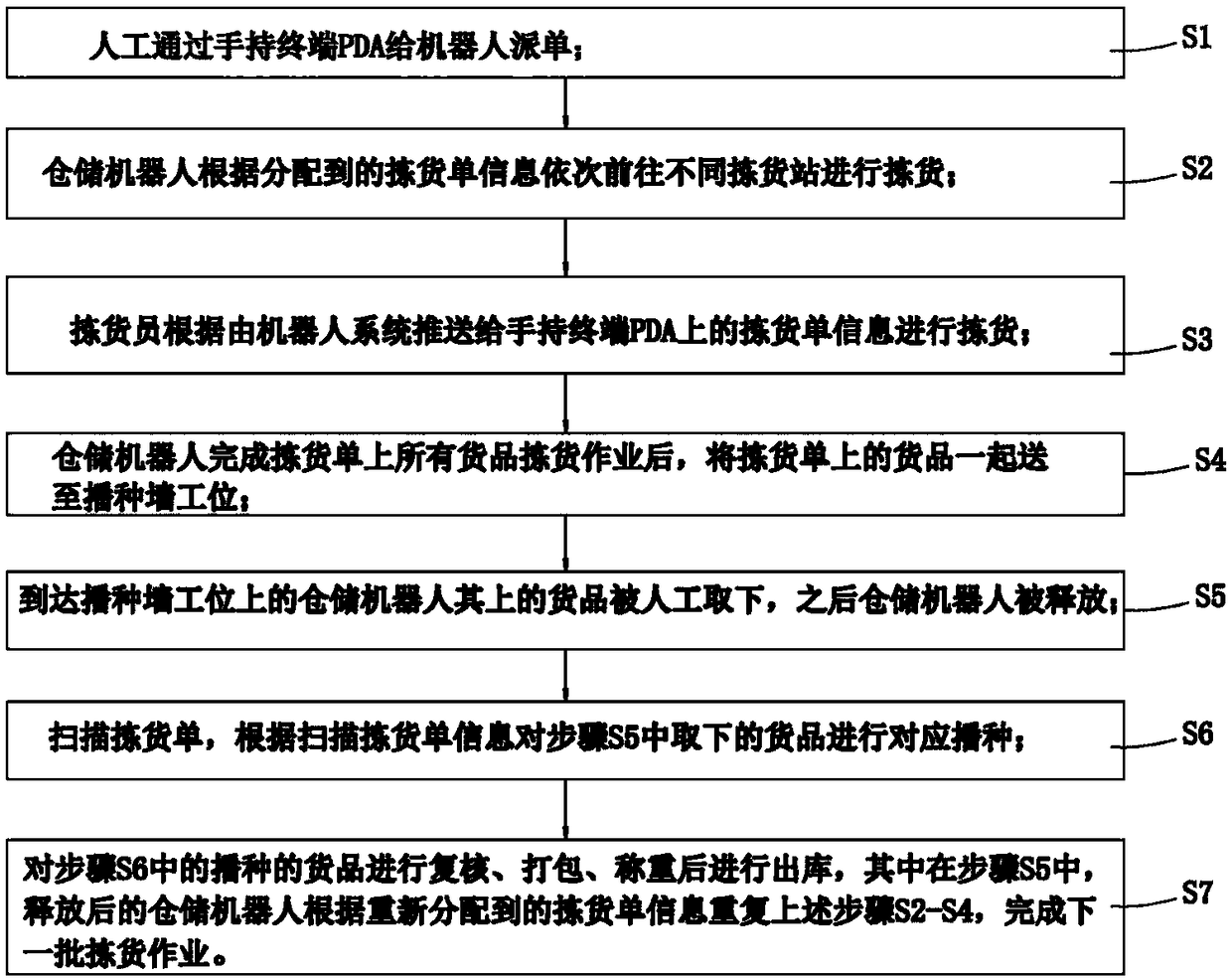

[0072] Reference figure 1 As shown, it shows a flowchart of an automatic sorting method for a warehouse robot in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com