A kind of residual activated sludge anaerobic gas production process

A residual activity and sludge technology, applied in sludge treatment, biological sludge treatment, electrochemical sludge treatment, etc., can solve the problems of slow hydrolysis steps, low methane production, long start-up period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

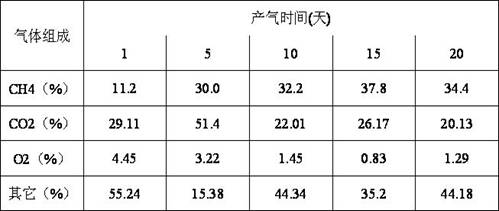

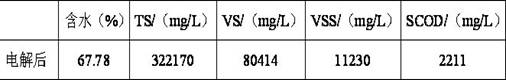

[0028] The specific example of the present invention is illustrated by taking the excess sludge of a certain urban sewage treatment plant as an example. Take 10kg of excess sludge for dehydration treatment until the volume moisture content is 85.02%, put the dehydrated sludge into the electrolytic cell, add 4g of polyether modified trisiloxane and 8g of 10% ethylenediaminetetraacetic acid to it , add the auxiliary agent polymycin 2g, after stirring, the electrolytic cell is electrified, at 10mA / cm 2 , under 200HZ for 1h, the residual activated sludge raw material and sludge after electrolytic treatment were sampled and analyzed for sludge composition as shown in Table 1. The sludge after electrolytic treatment is sent to the anaerobic reactor. Add the inoculum sludge to the reactor, the amount of the inoculation sludge is 1 / 5 of the volume of the remaining sludge, the inoculum sludge comes from the anaerobic digestion tank of a municipal sewage treatment plant, and the supern...

Embodiment 2

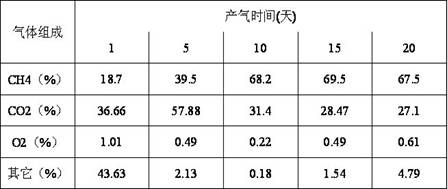

[0034] It is basically the same as Example 1, except that the wall-breaking agent is 10 g of polyether-modified trisiloxane and 6 g of 15% ethylenediamine tetraacetic acid, and 2 g of polymycin and nikkomycin are added as auxiliary agents. Gas production started after 8 days. See Table 3 for the sludge composition after pretreatment, and Table 4 for the gas composition.

[0035] Table 3 Sludge composition before and after pretreatment of excess sludge

[0036]

[0037] Table 4 Composition analysis table of produced gas

[0038]

Embodiment 3

[0040] It is basically the same as Example 1, except that the wall-breaking agent is 5 g of polyether-modified trisiloxane and 8 g of 15% ethylenediamine tetraacetic acid, and 2 g of nikkomycin is added. Gas production started after 10 days. The sludge composition after pretreatment is shown in Table 5, and the gas composition is shown in Table 6.

[0041] Table 5 Sludge composition before and after pretreatment of excess sludge

[0042]

[0043] Table 6 Composition analysis table of gas production

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com