A kind of powder for liquid biodegradable mulch film and preparation method

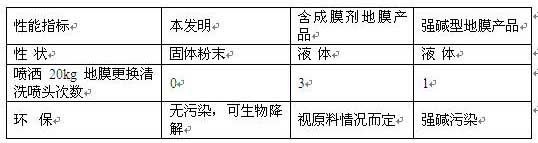

A biodegradable, powder-based technology, applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of inconvenient storage and transportation of liquid mulch, easy blockage of spraying device flow channels, difficulty in storage of liquid mulch, etc., to achieve the source of raw materials Convenience, simple and reliable process, and the effect of preventing water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

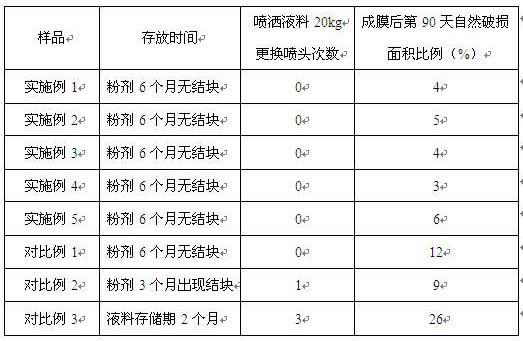

Examples

Embodiment 1

[0028] (1) Mix 40 parts of alginic acid, 5 parts of calcium acetate, 9 parts of gluconolactone, 20 parts of wood fiber, and 5 parts of polyacrylamide in parts by weight to obtain a film-forming material; mix 3 parts of bentonite and 0.2 parts of water Evenly, the bentonite is moistened to form small granular bentonite; then the small granular bentonite is added to the film-forming material, after mixing, sieve through a rotary sieve, and form spherical particles through the bonding of bentonite;

[0029] (2) Put the spherical particles obtained in step (1) into the fluidized bed, set the temperature of the fluidized bed to 60°C, and the air inlet speed to 40m 3 / h, 10 parts by weight of urea are added to the fluidized bed in batches within 5 minutes, and then the fluidization time is kept for 5 minutes. In the fluidized bed, the urea is melted and wrapped on the surface of spherical particles, and a liquid for use in liquid is obtained after cooling. Powder for biodegradable m...

Embodiment 2

[0031] (1) Mix 50 parts of alginic acid, 8 parts of calcium chloride, 10 parts of gluconolactone, 25 parts of wood fiber and 6 parts of polyacrylamide in parts by weight to obtain a film-forming material; mix 4 parts of bentonite and 0.1 part of water Mix evenly to moisten the bentonite to form small granular bentonite; then add small granular bentonite to the film-forming material, after mixing, sieve through a rotary sieve, and form spherical particles through the bonding of bentonite;

[0032] (2) Put the spherical particles obtained in step (1) into the fluidized bed, set the temperature of the fluidized bed to 60°C, and the air inlet speed to 50m 3 / h, 10 parts by weight of urea are added to the fluidized bed in batches within 5 minutes, and then the fluidization time is kept for 6 minutes. In the fluidized bed, urea is melted and wrapped on the surface of spherical particles, and after cooling, a liquid for use in a liquid state is obtained. Powder for biodegradable mulc...

Embodiment 3

[0034] (1) Mix 55 parts of alginic acid, 5 parts of calcium gluconate, 9 parts of gluconolactone, 35 parts of wood fiber and 10 parts of polyacrylamide in parts by weight to obtain a film-forming material; mix 5 parts of bentonite and 1 part of water Mix evenly to moisten the bentonite to form small granular bentonite; then add small granular bentonite to the film-forming material, after mixing, sieve through a rotary sieve, and form spherical particles through the bonding of bentonite;

[0035] (2) Put the spherical particles obtained in step (1) into the fluidized bed, set the temperature of the fluidized bed to 60°C, and the air inlet speed to 60m3 / h, 15 parts by weight of urea are added to the fluidized bed in batches within 5 minutes, and then the fluidization time is kept for 8 minutes. In the fluidized bed, the urea is melted and wrapped on the surface of spherical particles, and a liquid for use in liquid is obtained after cooling. Powder for biodegradable mulch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com