Four-season universal test sealant and preparation method and production device thereof

A technology for general testing and production equipment, applied in chemical instruments and methods, plastic/resin/wax insulators, organic insulators, etc. Shear stability, less decomposition, good hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

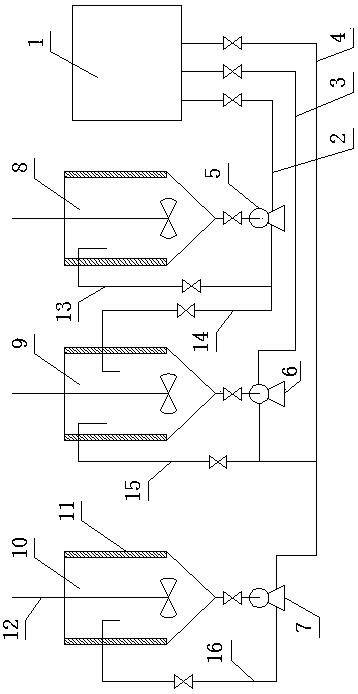

Method used

Image

Examples

Embodiment 1

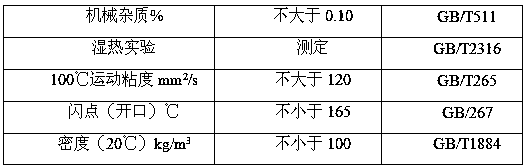

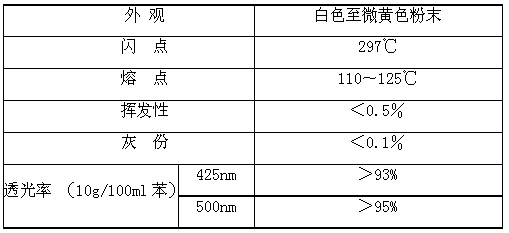

[0054] The four-season general-purpose test sealant of the present invention is composed of the following materials in proportion by weight: 10 parts of medium molecular polyisobutylene, 5 parts of low molecular polyisobutylene, 1 part of fumed silica, 10 parts of diethyl silicone oil, polyα- 20 parts of olefin synthetic oil, 1 part of diester, 0.1 part of antioxidant, 0.1 part of rust inhibitor, and 1 part of pour point depressant.

[0055] The method for preparing the above-mentioned four-season universal test sealant is as follows:

[0056] a. Preparation of the first base agent, disperse and react medium-molecular-weight polyisobutylene, low-molecular-weight polyisobutylene, and diethyl silicone oil at a constant temperature of 160°C with a stirring speed of 90 r / min for 2 hours at a high speed to obtain the first base agent preparation;

[0057] b. Preparation of the second base agent. After mixing the antioxidant, diester, and fumed silica, keep the temperature at 100° C...

Embodiment 2

[0061] The four-season general-purpose test sealant of the present invention is composed of the following materials in proportion by weight: 30 parts of medium molecular polyisobutylene, 20 parts of low molecular polyisobutylene, 10 parts of fumed silica, 30 parts of diethyl silicone oil, polyα- 40 parts of olefin synthetic oil, 20 parts of diester, 2.0 parts of antioxidant, 2.0 parts of rust inhibitor, 5 parts of pour point depressant.

[0062] The method for preparing the above-mentioned four-season universal test sealant is as follows:

[0063] a. Preparation of the first base agent, disperse and react medium-molecular-weight polyisobutylene, low-molecular-weight polyisobutylene, and diethyl silicone oil at a constant temperature of 200°C with a stirring speed of 100 r / min for 4 hours at a high speed to obtain the first base agent preparation;

[0064] b. Preparation of the second base agent, after mixing the antioxidant, diester, and fumed silica, at a constant temperature...

Embodiment 3

[0068] The four-season general-purpose test sealant of the present invention is composed of the following materials in proportion by weight: 15 parts of medium molecular polyisobutylene, 10 parts of low molecular polyisobutylene, 2 parts of fumed silica, 15 parts of diethyl silicone oil, polyα-olefin 25 parts of synthetic oil, 10 parts of diester, 0.5 part of antioxidant, 0.5 part of rust inhibitor, 1 part of pour point depressant.

[0069] The method for preparing the above-mentioned four-season universal test sealant is as follows:

[0070] a. Preparation of the first base agent, disperse and react medium-molecular-weight polyisobutylene, low-molecular-weight polyisobutylene, and diethyl silicone oil at a constant temperature of 180°C with a stirring speed of 95 r / min for 3 hours at a high speed to obtain the first base agent preparation;

[0071] b. Preparation of the second base agent. After mixing the antioxidant, diester, and fumed silica, keep the temperature at 110° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com