Modified multifunctional coal cake manufacturing device

A kind of manufacturing equipment and multi-functional technology, applied in the field of briquette manufacturing, can solve the problems of affecting work efficiency, increasing workload, increasing equipment purchase cost, etc., and achieves the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

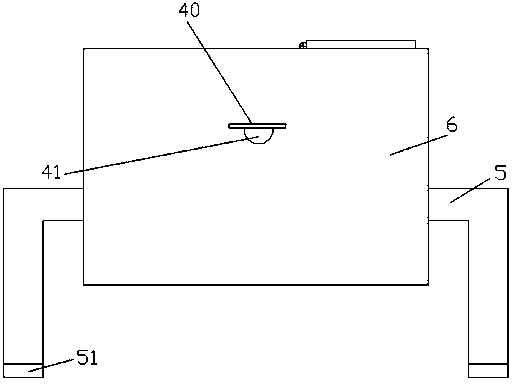

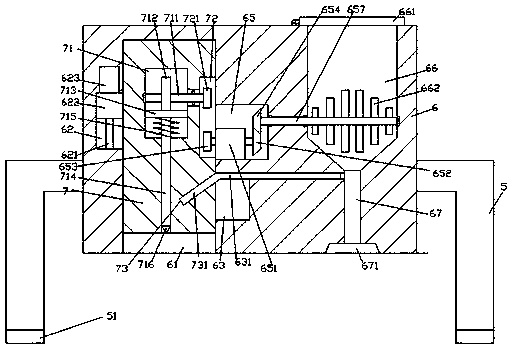

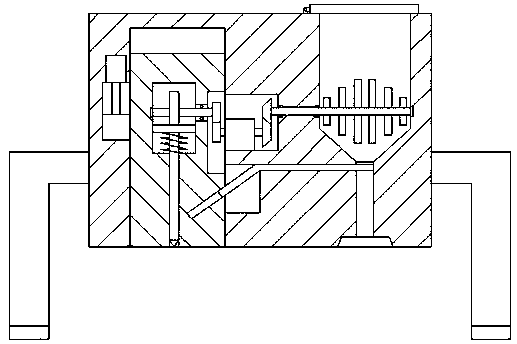

[0015] Such as figure 1 , figure 2 with image 3 As shown, an improved multifunctional briquette manufacturing equipment of the present invention includes an outer casing 6, the left and right end faces of the outer casing 6 are fixed by the left and right L-shaped support columns 5, and the bottom end surfaces of the L-shaped support columns 5 are fixedly arranged There is a foot pad 51, and the bottom end surface on the left side of the outer casing 6 is provided with a first sliding groove 61 that is expanded upwards, and a sliding frame 7 is connected in translation in the first sliding groove 61, and the outer casing 6. The top end surface on the right side is provided with a downwardly expanding mixing cavity 66, and the bottom of the mixing cavity 66 is slightly connected with a downwardly expanding discharge groove 67. The discharge groove 67, the first A sliding groove 61 left inner wall is provided with an up and down sliding device for cooperating with the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com