Preparation method of seaweed beer based on marine microbial ferment and obtained seaweed beer

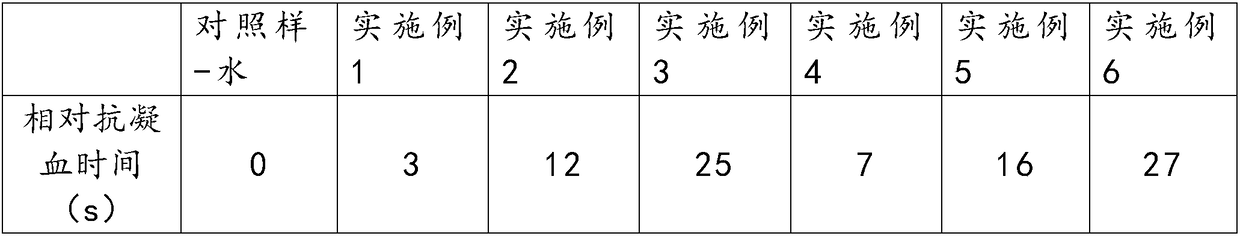

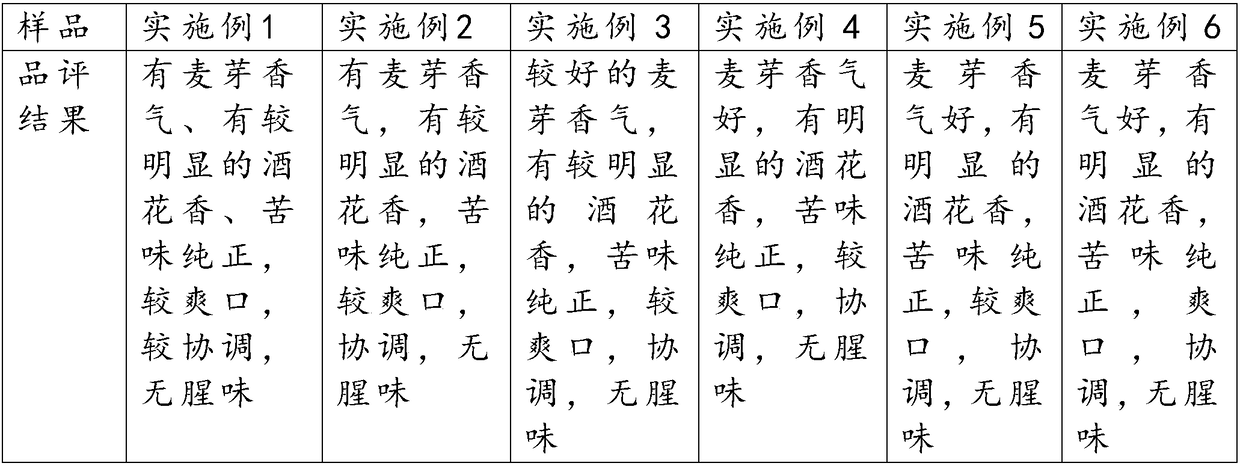

A technology of marine microorganisms and seaweed enzymes, applied in the field of food processing, can solve problems such as the fishy smell of seaweed, and achieve the effects of pure bitterness, good drinkability and obvious hop aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Embodiments of the present invention provide a method for preparing seaweed beer based on marine microbial enzymes, comprising the following steps:

[0022] S1: Preparation of seaweed enzyme:

[0023] Select clean seaweed raw materials that meet food hygiene standards, rehydrate fresh seaweed raw materials or dry raw materials, cut them, add water at a ratio of 1:10 by weight and homogenize them, then transfer them to fermentation tanks, stir and sterilize, and cool down to 40± Store at 2°C for later use. Food grade Bacillus subtilis solid dry powder inoculum (10 10 CFU / g) is prepared into 10% bacterial suspension with sterile physiological saline before inoculation, Lactobacillus plantarum dry powder microbial agent (10 9 CFU / g) was prepared into 10% bacterial suspension with sterile physiological saline before inoculation. The sterilized fermentation substrate is kept at 40°C, and the prepared Bacillus subtilis suspension is aseptically inserted into the prepared B...

Embodiment 1

[0037]Step 1: Preparation of red algae enzyme: fresh red algae raw materials or dried red algae are rehydrated, cut, added water and homogenized, then transferred to a fermentation tank for sterilization, and the sterilized fermentation substrates are successively inserted into subtilis at different temperatures Bacillus suspension and Lactobacillus plantarum suspension are fermented, and the fermented seaweed enzyme is obtained by solid-liquid separation to obtain red algae enzyme;

[0038] Step 2: Preparation of wort: Take a certain amount of malt and rice, of which malt accounts for 60%-70%, after crushing, saccharify according to the material-water ratio of 1: (3-4), and the saccharification temperature is 63-65°C , the saccharification time is 60-80min. After the saccharification is completed, the wort is filtered, and then boiled for 45-75min. During the boiling process, hops are added. After the boiling is completed, the wort is cooled by a thin plate and enters the ferm...

Embodiment 2

[0042] The technical process is the same as in Example 1, except that the prepared seaweed enzyme is green algae enzyme, and the mass percentage of the added green algae enzyme is 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com