Integrated efficient windowing sidetrack drilling tool

A window-opening sidetracking and high-efficiency technology, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problems of increased construction period, low overall efficiency, large remaining length of high-pressure pipes, etc., to reduce the cost of tripping. The number of times, the use of safe and reliable, the effect of high success rate of window opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

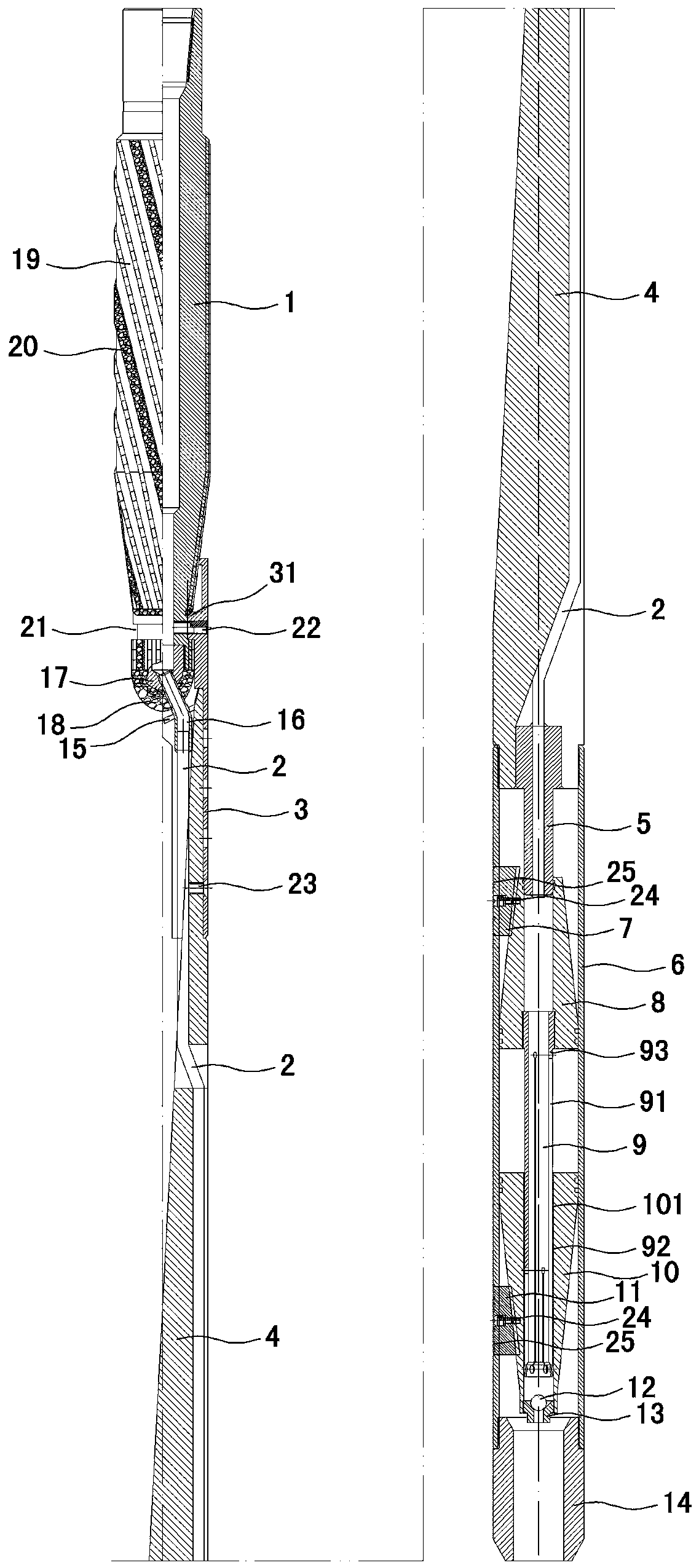

[0008] like figure 1 As shown, it includes milling cone 1, high pressure pipe 2, protection cylinder 3, inclined iron 4, inlet pipe 5, piston cylinder 6, several upper tooth blocks 7, upper piston 8, distribution pipe 9, lower piston 10, several blocks The lower block 11, the steel ball 12, the ball seat 13 and the lead 14, the lower end of the milling cone 1 is axially connected to the upper end of the protection cylinder 3, the upper end of the inclined iron 4 is axially connected to the protection cylinder 3, and the lower end of the inclined iron 4 is connected to the protection cylinder 3. The upper end of the piston cylinder 6 is axially connected, the lower end of the piston cylinder 6 is axially connected with the upper end of the lead 14, the inlet pipe 5 is located in the piston cylinder 6, the upper end is axially connected with the lower end of the inclined iron 4, and the high pressure pipe 2 is installed on the inclined iron 4. The upper and lower ends are commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com