A high-pressure water pump outlet control valve

A high-pressure water pump and control valve technology, applied in valve details, valve devices, multi-port valves, etc., can solve the problems of easy wear of the pressure relief orifice, unstable pre-charge pressure, corrosion, etc., and achieve good anti-coking powder wear performance. , Turn on the effect of large flow coefficient and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

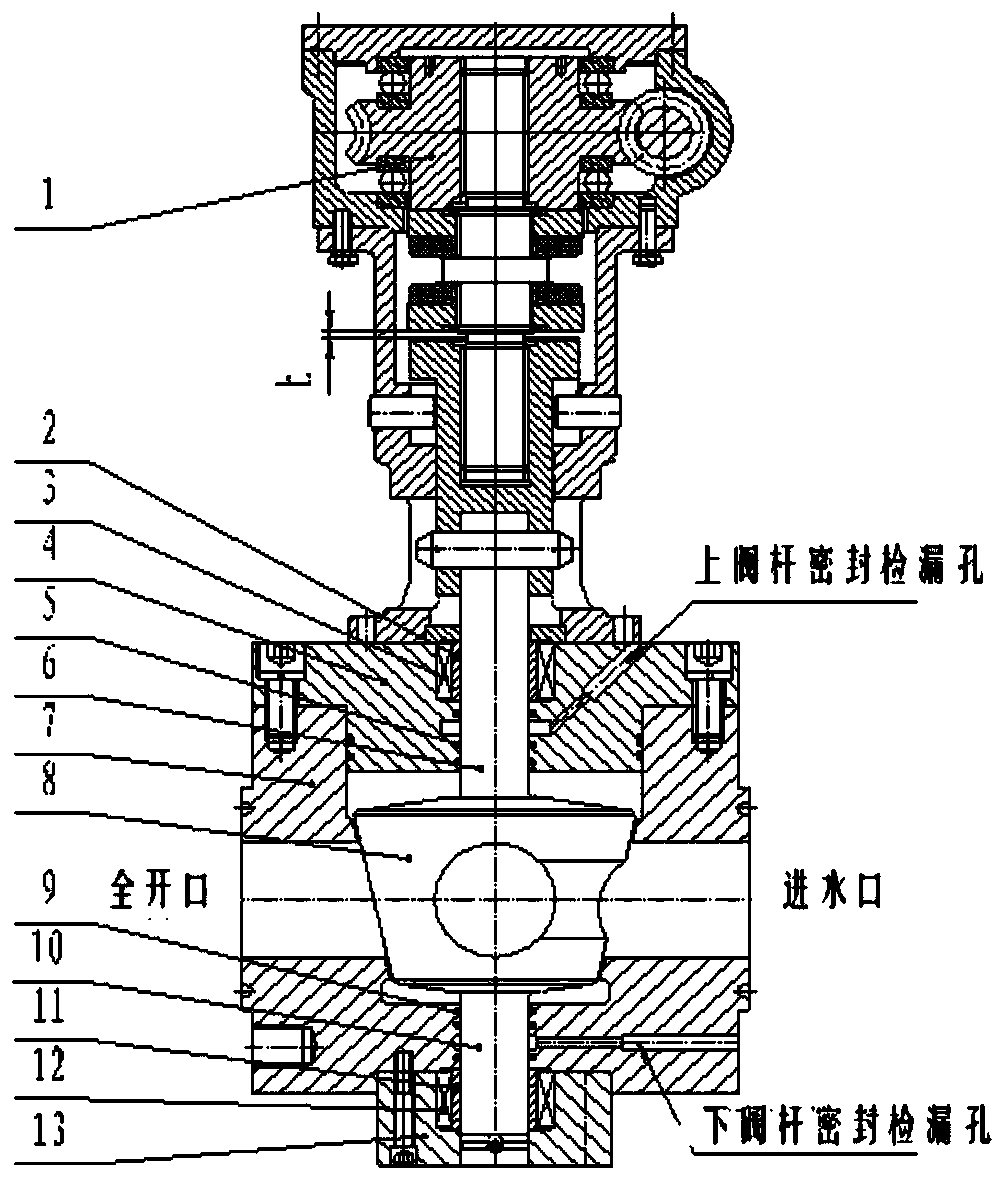

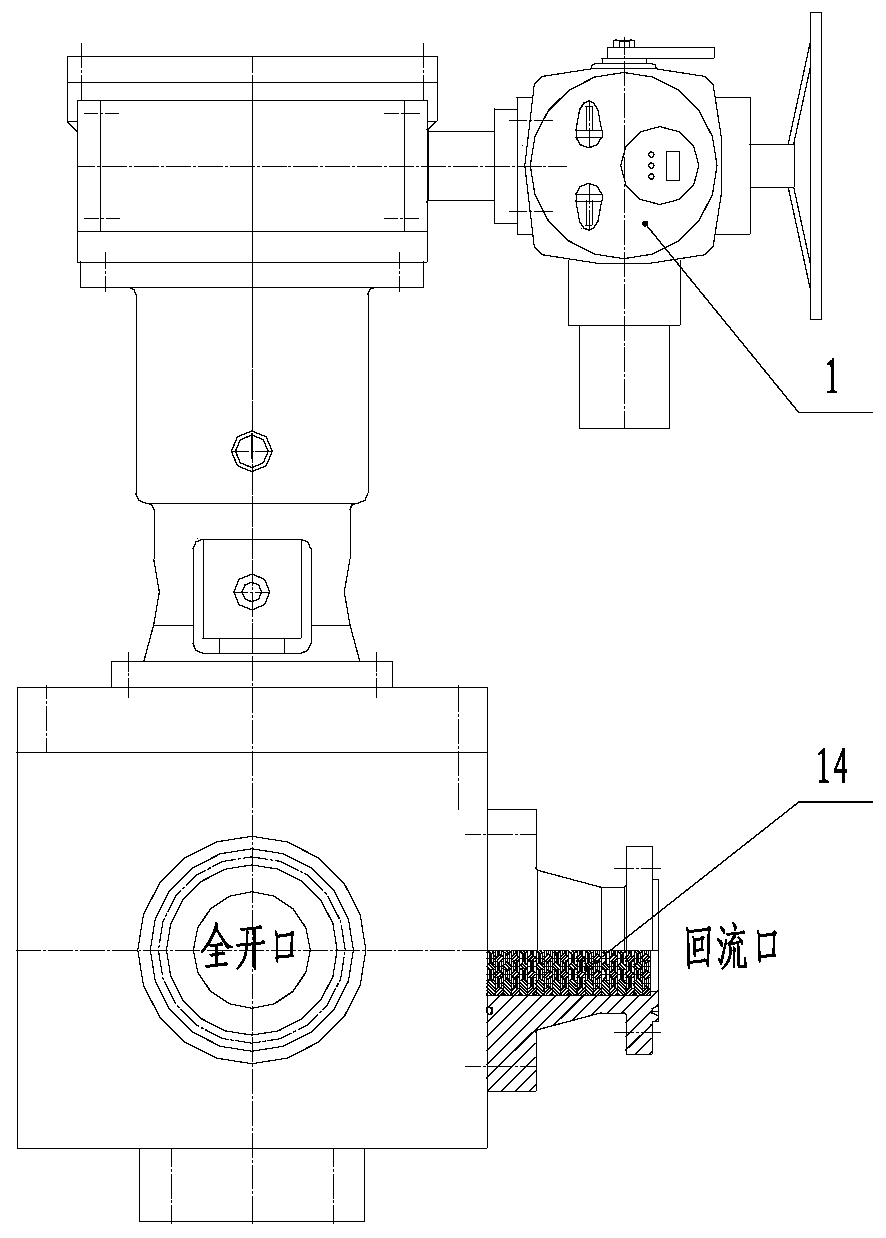

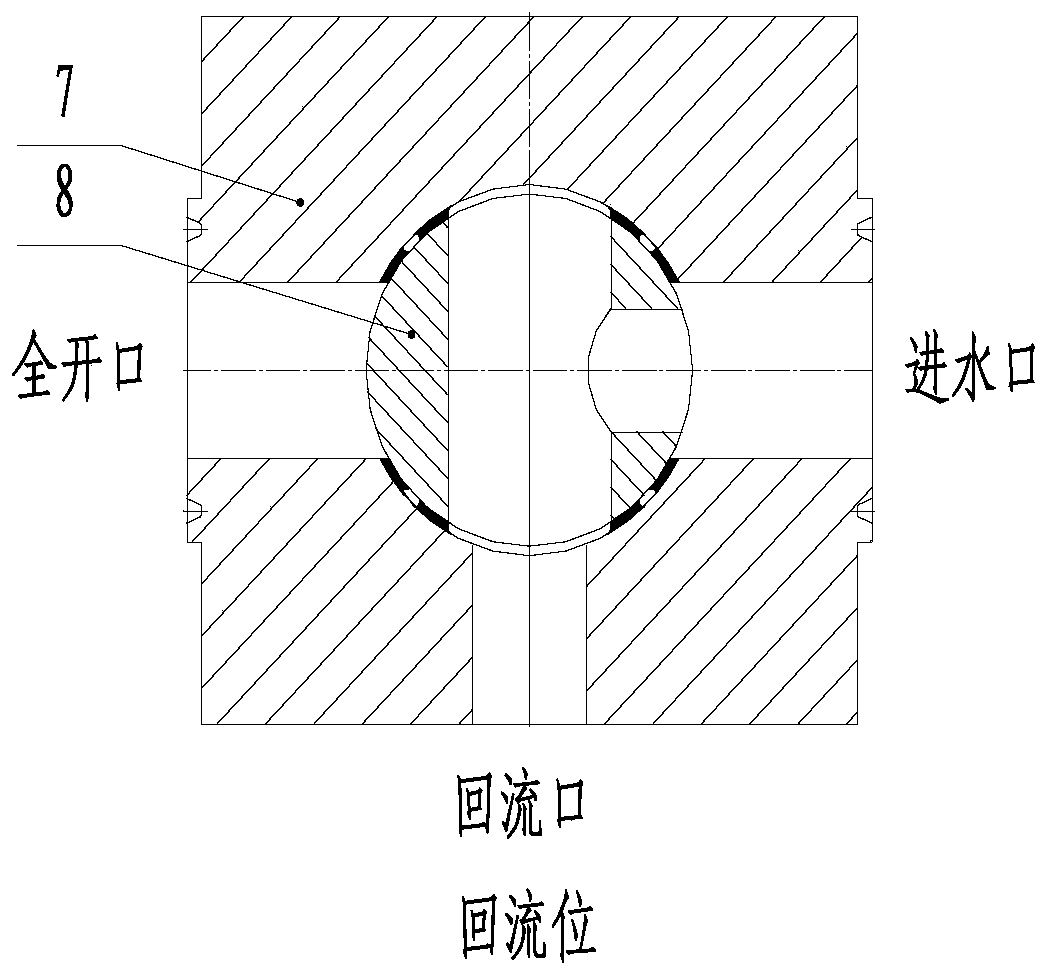

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a high-pressure water pump outlet control valve according to the present invention includes an electric actuator 1, a wear-resistant sleeve I2, a radial ball bearing I3, a valve cover 4, a seal I5, an upper valve stem 6, a valve body 7, Spool 8, seal II 9, lower valve stem 10, wear-resistant sleeve II 11, radial ball bearing II 12, support end cover 13, return orifice plate 14, in which the electric actuator 1 is installed on the valve cover 4 for driving the valve The core 8 is lifted, rotated and lowered, which can realize the accurate positioning of the pre-fill position of the high-pressure water pump outlet control valve, and can accurately adjust the pre-charge pressure and flow rate, and zero leakage at the return position; the valve cover 4 and the valve body 7 are fixed by bolts, and the valve core 8 is installed in the inner cavity of the valve body 7, and the return orifice plate 14 ...

Embodiment 2

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a high-pressure water pump outlet control valve according to the present invention includes an electric actuator 1, a wear-resistant sleeve I2, a radial ball bearing I3, a valve cover 4, a seal I5, an upper valve stem 6, a valve body 7, Spool 8, seal II 9, lower valve stem 10, wear-resistant sleeve II 11, radial ball bearing II 12, support end cover 13, return orifice plate 14, in which the electric actuator 1 is installed on the valve cover 4 for driving the valve The core 8 is lifted, rotated and lowered, which can realize the accurate positioning of the pre-fill position of the high-pressure water pump outlet control valve, and can accurately adjust the pre-charge pressure and flow rate, and zero leakage at the return position; the valve cover 4 and the valve body 7 are fixed by bolts, and the valve core 8 is installed in the inner cavity of the valve body 7, and the return orifice plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com