An underwater electro-hydraulic reversing valve

A technology of electro-hydraulic reversing valve and pilot valve, applied in valve details, valve device, valve shell structure, etc., can solve the problems of difficult design and affect the independent development and localization of deep water control system, and achieve safe and reliable dynamic sealing effect, optimized volume and weight, sealed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

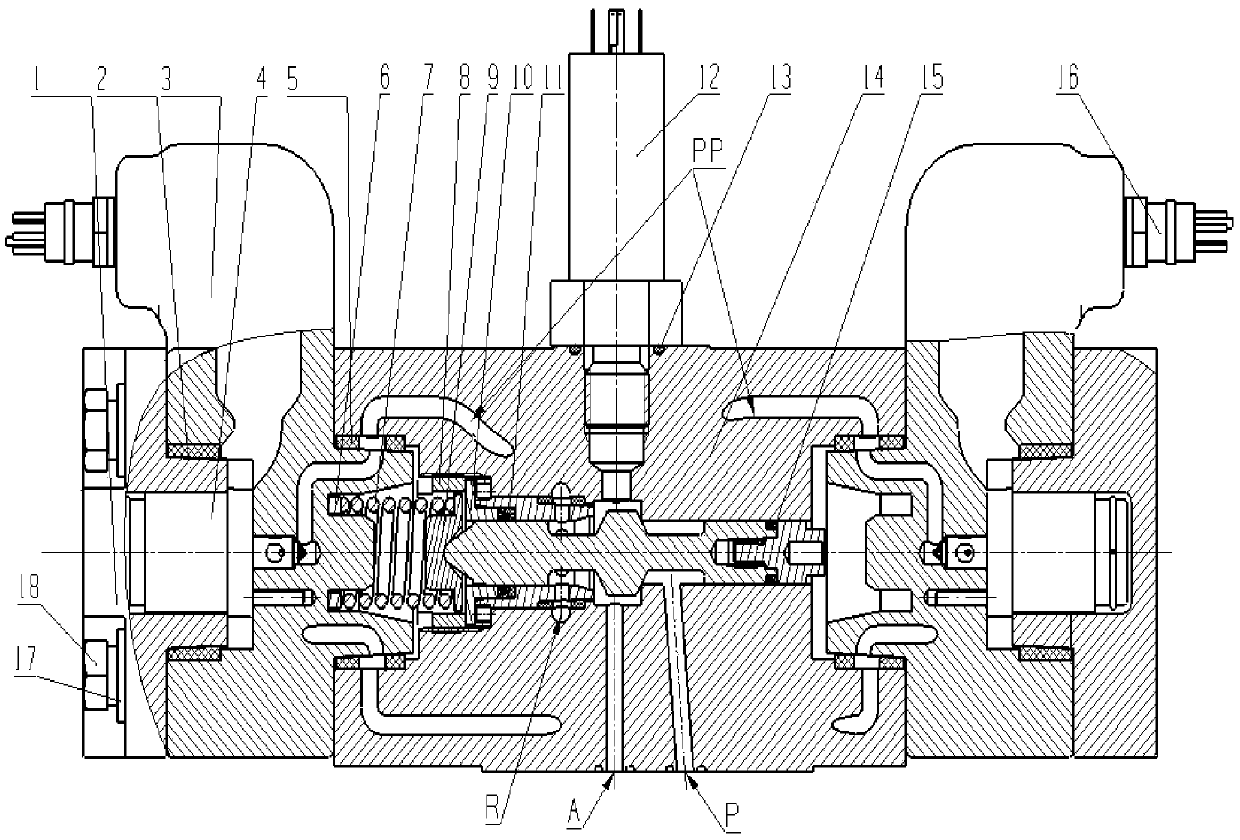

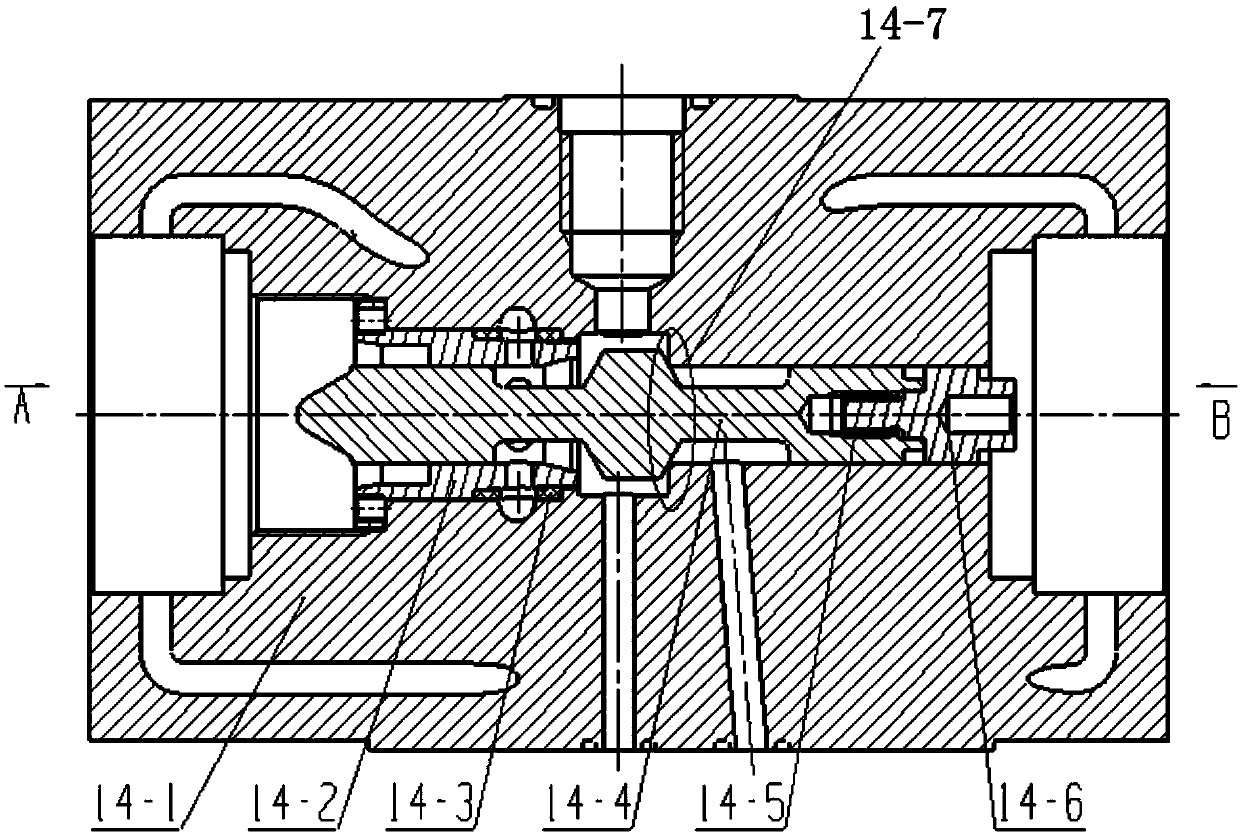

[0028] Such as Figure 1~2 As shown, an underwater electro-hydraulic reversing valve is characterized in that the reversing valve includes a pilot valve protective cover 1, a pilot valve protective cover sealing sleeve 2, a pilot valve seat 3, a pilot valve 4, and a pilot valve seat seal Sleeve 5, conversion spring 7, compression sleeve 8, spring seat 9, sleeve sealing top plate 10, first sealing cup 11, pressure sensor 12, circular section rubber sealing ring 13, housing valve assembly 14, second sealing Leather cup 15 and 5-core sealed electrical socket 16;

[0029] The pilot valve protective cover 1, the pilot valve protective cover sealing sleeve 2, the pilot valve seat 3, and the pilot valve 4 are all symmetrically distributed on both sides of the pressure sensor axis, which are respectively the left and right pilot valves, the left and right pilot valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com