Coordinated control method and device for synchronous phase modifier and LCC-HVDC (line-commutated-converter high voltage direct current)

An LCC-HVDC, coordinated control technology, applied in the field of coordinated control between the synchronous camera and LCC-HVDC, can solve the problem of weak resistance to commutation failure, and achieve the goal of improving the resistance and reducing the probability of commutation failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

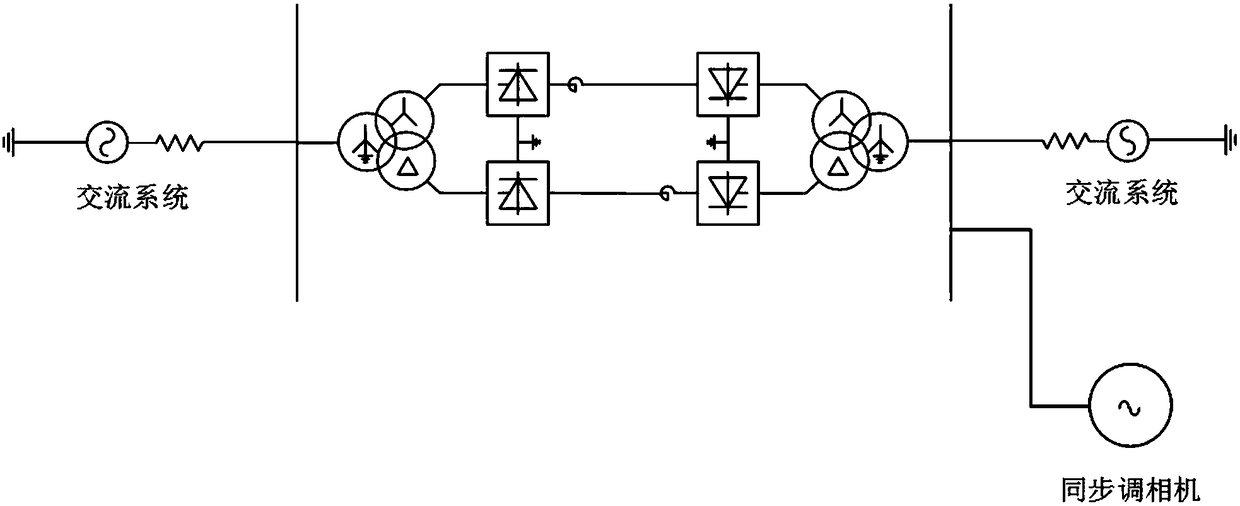

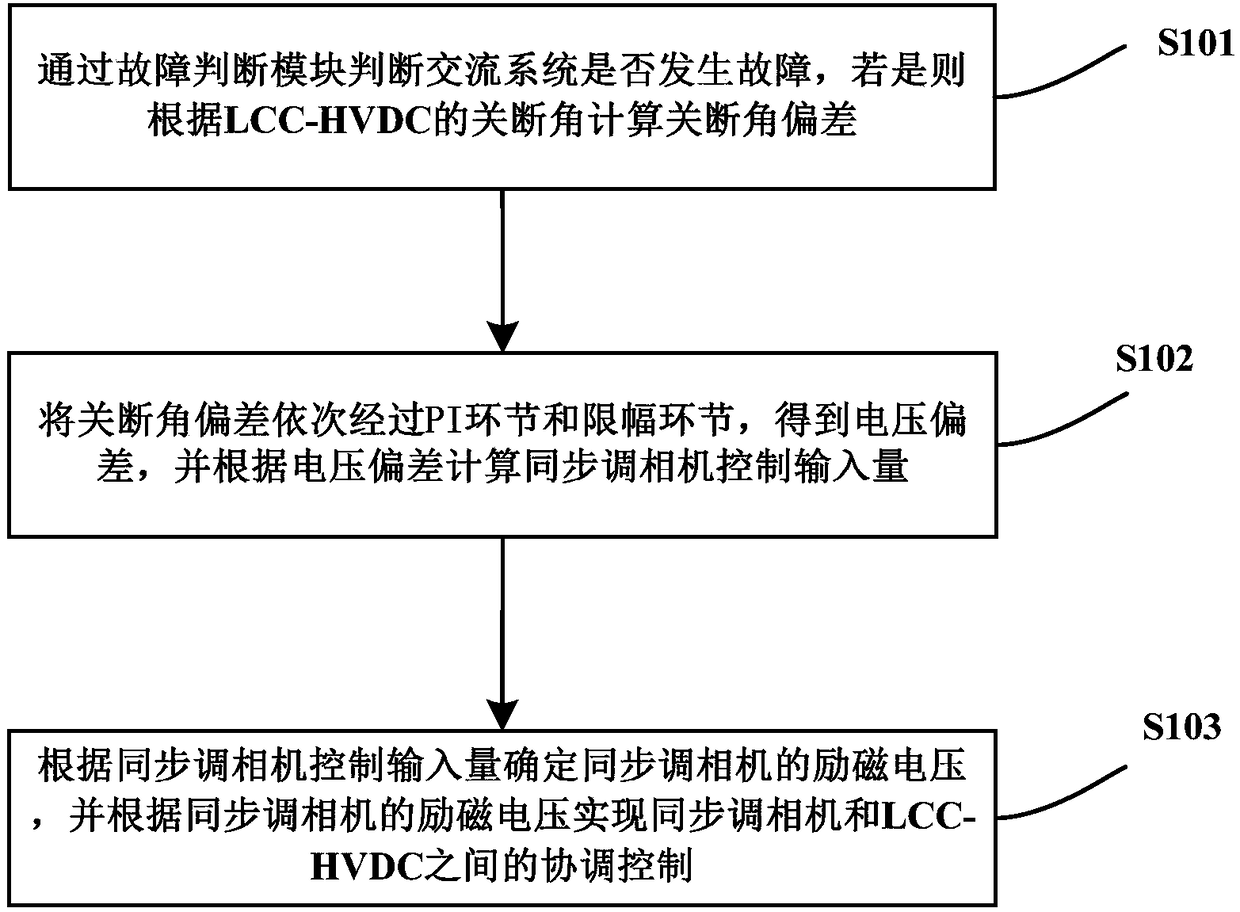

[0046] The embodiment of the present invention provides a coordinated control method between a synchronous condenser and an LCC-HVDC. The structure diagram of an LCC-HVDC connected to a synchronous condenser is as follows figure 1As shown, the specific flow chart of the coordinated control method between the synchronous condenser and the LCC-HVDC is as follows figure 2 As shown, the specific process is as follows:

[0047] S101: Use the fault judgment module to judge whether the AC system has a fault, and if so, calculate the cut-off angle deviation according to the cut-off angle of the LCC-HVDC;

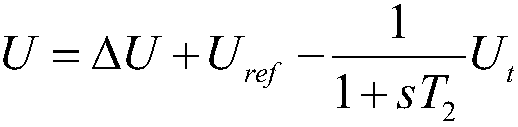

[0048] S102: Pass the turn-off angle deviation through the PI link and the limiting link in sequence to obtain the voltage deviation, and calculate the synchronous condenser control input amount according to the voltage deviation;

[0049] S103: Determine the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com