Miniature automatic wire detaching device for motor

A technology of automatic dismantling and small motors, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve problems that affect work efficiency, excessive dust, and threats to the health of operators, so as to increase work efficiency and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples. The examples are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

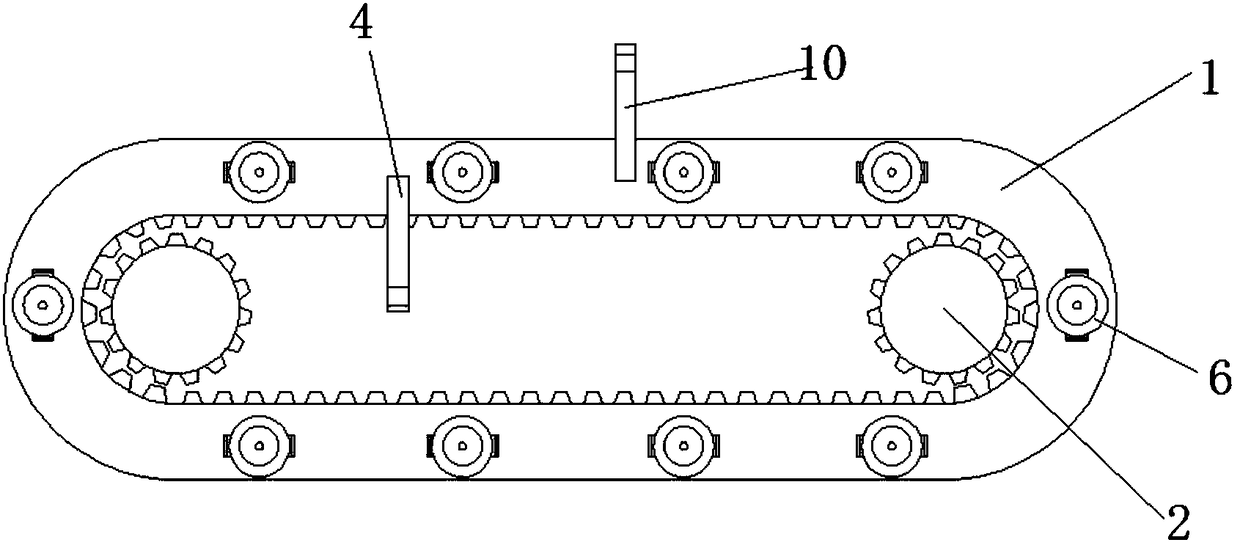

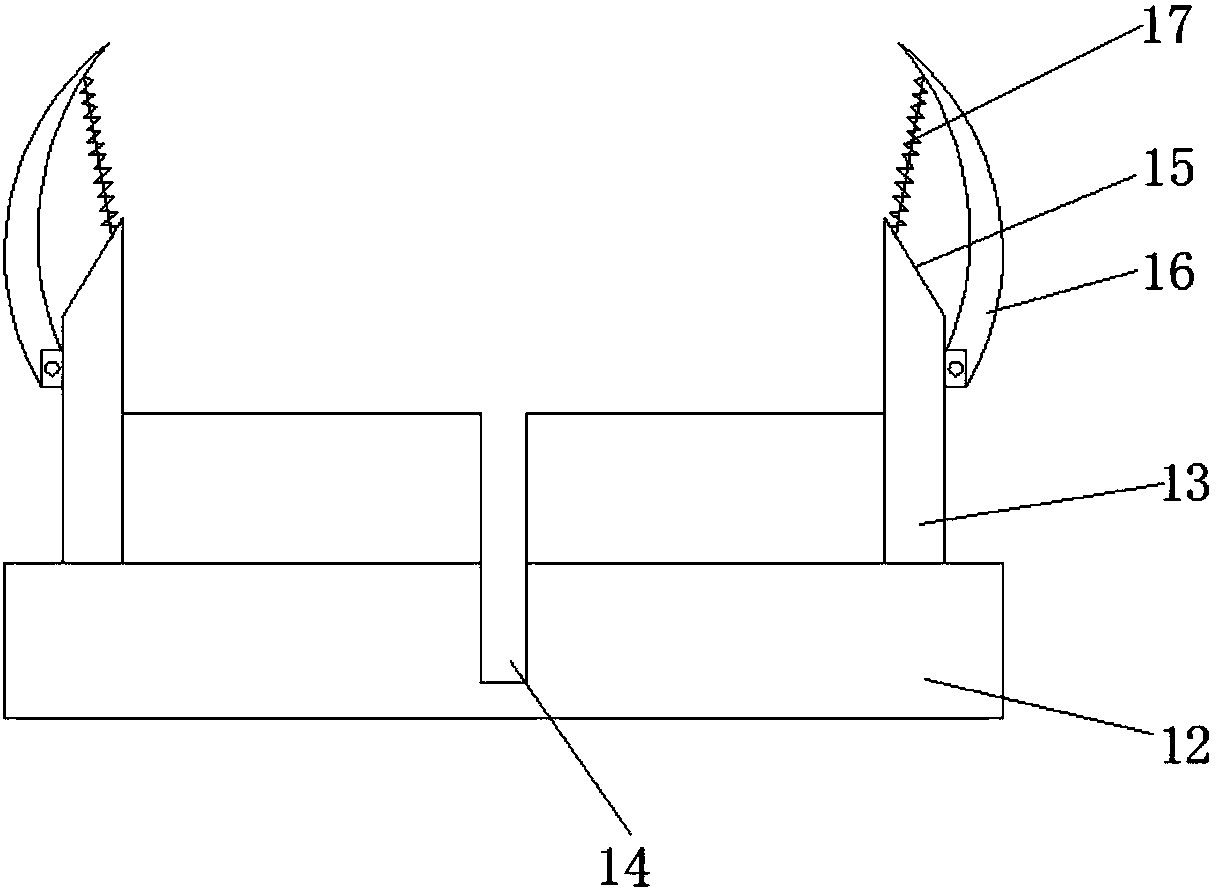

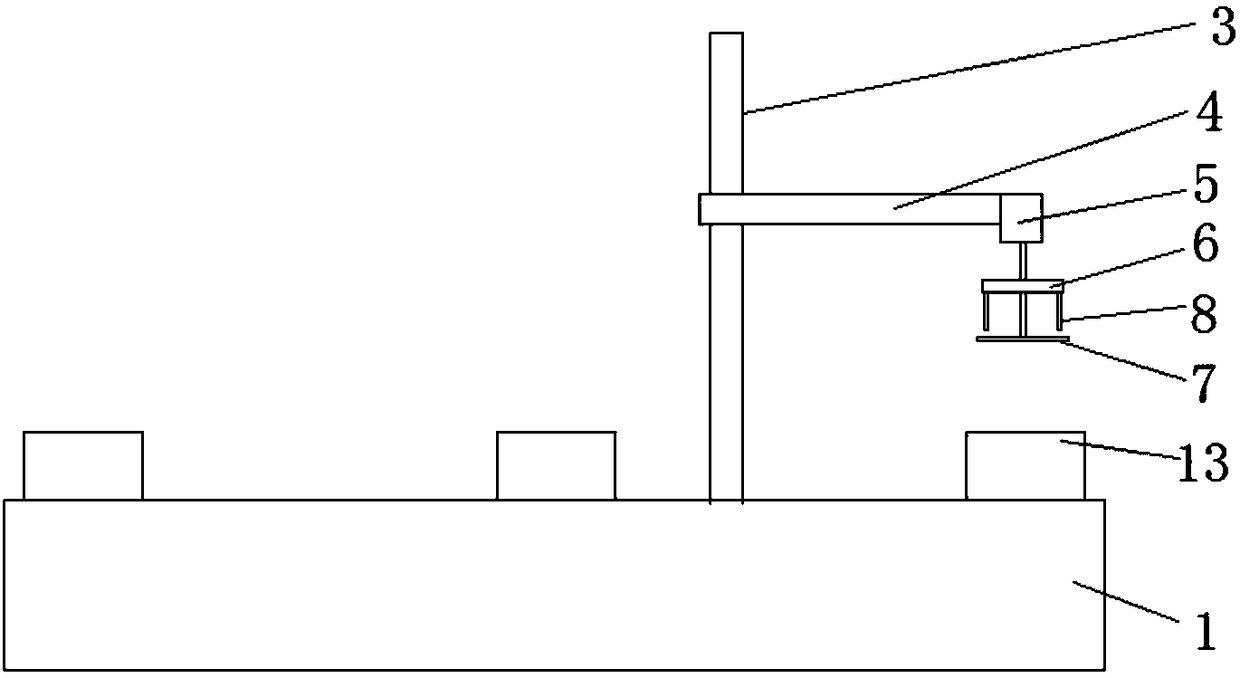

[0019] like Figure 1 to Figure 4 As shown, a small-sized motor automatic disconnecting device includes a transmission mechanism, a motor fixing mechanism, a motor cutting mechanism and a winding recovery mechanism. The transmission mechanism includes a transmission track 1 with gears on the inner ring, and is arranged There is a rotating gear 2 meshing with the transmission track 1, and the rotation gear 2 is driven by a driving motor, and the driving motor adopts a stepping motor; the transmission track 1 is arranged in a ring shape, and several uniformly spaced motor fixing mechanisms are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com