Welding gun clamping device for high-position welding

A welding torch clamp and high-position technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low safety factor of herringbone ladder, difficulty in moving scaffolding, and large amount of use, and achieve compact structure, high safety factor, high safety factor, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

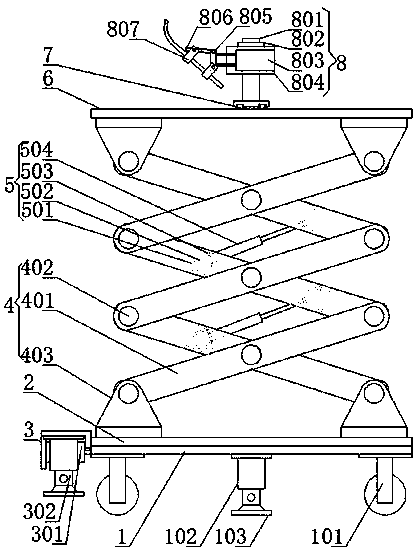

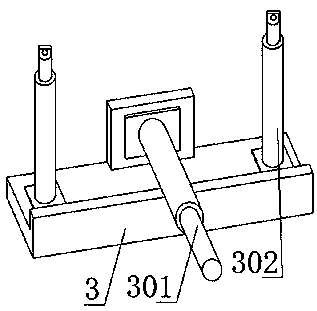

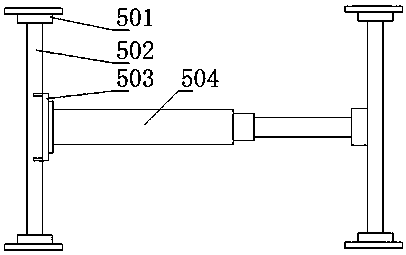

[0020] Such as figure 1 As shown in , a torch clamping device for high-position welding, including a base plate 1, a sliding plate 2, a grooved plate 3, a fork frame group 4, a lifting mechanism 5, a panel 6, a sliding mechanism 7, a clamping Mechanism 8, the four corners of the lower plane of the base plate 1 are connected with rollers 101, the middle of the four sides of the base plate 1 are connected with supporting cylinders 102, the upper plane of the base plate 1 is connected to the lower plane of the sliding plate 2 through the guide rail guide groove, and the sliding plate 2. One side is connected to the narrow facade of the slotted plate 3, the two ends of the bottom surface of the slotted plate 3 are connected to the supporting cylinder 103, the inner side of the block facade of the slotted plate 3 is connected to the pulling cylinder 301, and the stretching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com