Adjustable mirror surface rolling device

A rolling device and adjustable technology, which is applied in the field of adjustable mirror rolling devices, can solve problems such as single function, poor applicability, and inability to adjust parts to be processed, and achieve the effects of easy stability of workpieces, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

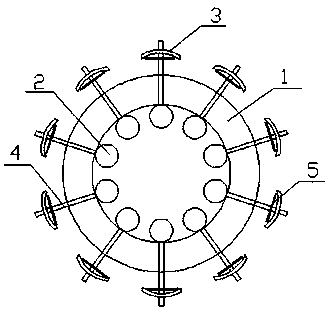

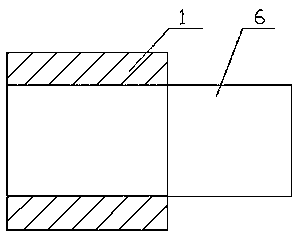

[0016] Such as figure 1 , 2 As shown, an adjustable mirror rolling device includes a mandrel 1 and grinding rods 2 uniformly distributed on the inner wall of the mandrel 1. An arc-shaped pull plate 3 is arranged on the periphery of the mandrel 1, and the arc-shaped pull plate 3 passes through the mandrel. The connecting rod 4 of 1 is fixedly connected with the grinding rod 2. The grinding rod 2 and the connecting rod 4 are fixedly connected by welding. , the arc-shaped pull plate 3 is a silica gel plate, a gasket 5 is arranged between the arc-shaped pull plate 3 and the mandrel 1, and a guide sleeve 6 is provided on one side of the mandrel 1, and the inner diameter of the guide sleeve 6 is the same as the inner diameter of the mandrel 1.

[0017] When in use, insert the pipe body to be processed into the mandrel 1 from the side of the guide sleeve 6, and then adjust the grinding rod 2 to fix the pipe body. Tightly fixed to prevent the grinding rod 2 from shifting during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com