Index card automatically film laminating machine

An index card and film laminating machine technology, which is applied to lamination devices, sending objects, folding thin materials, etc., can solve the problems of limited production efficiency, increased product defective rate, and high labor intensity of workers, and achieves accurate film placement and reduced Labor intensity, the effect of improving product qualification rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

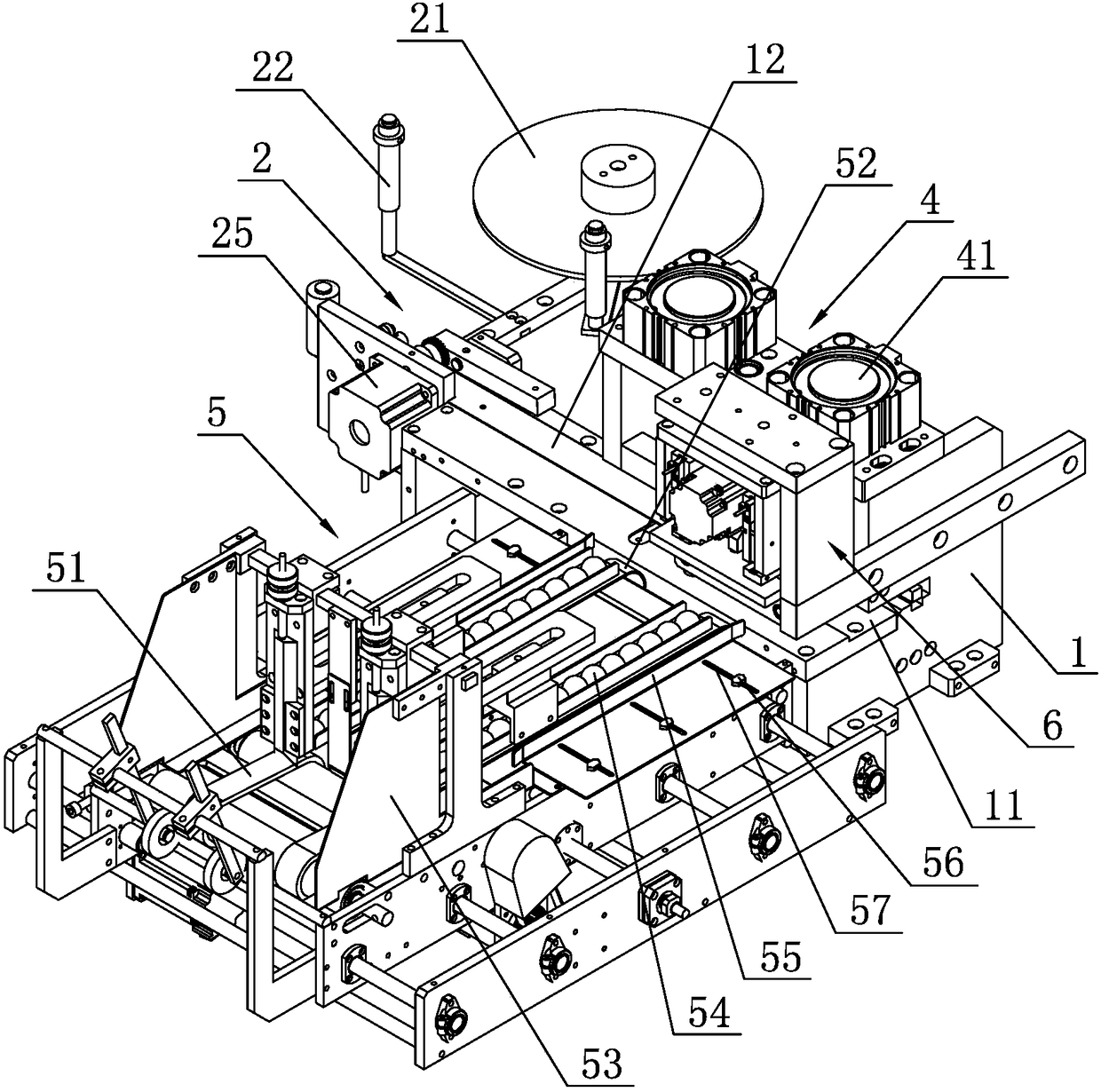

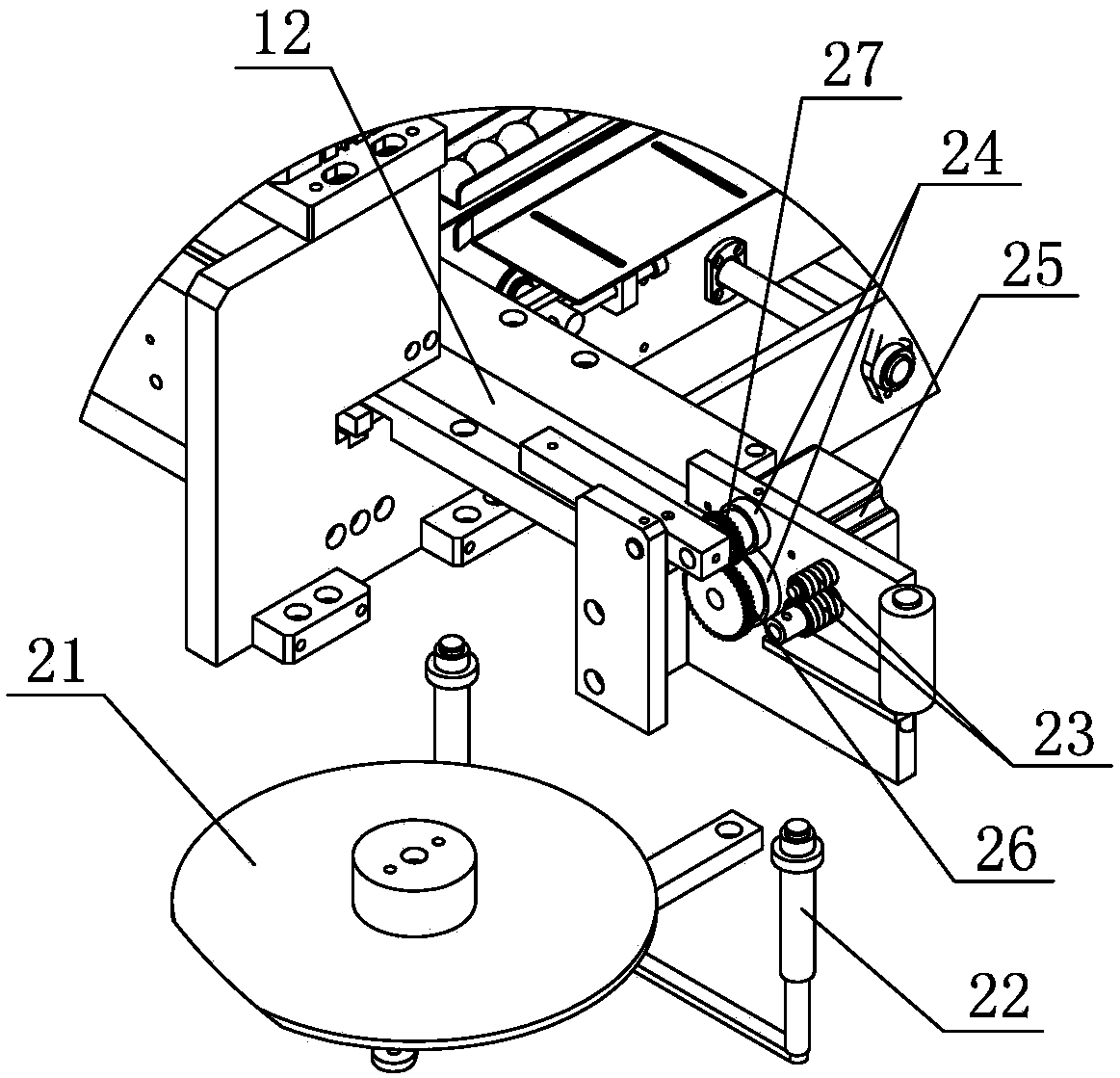

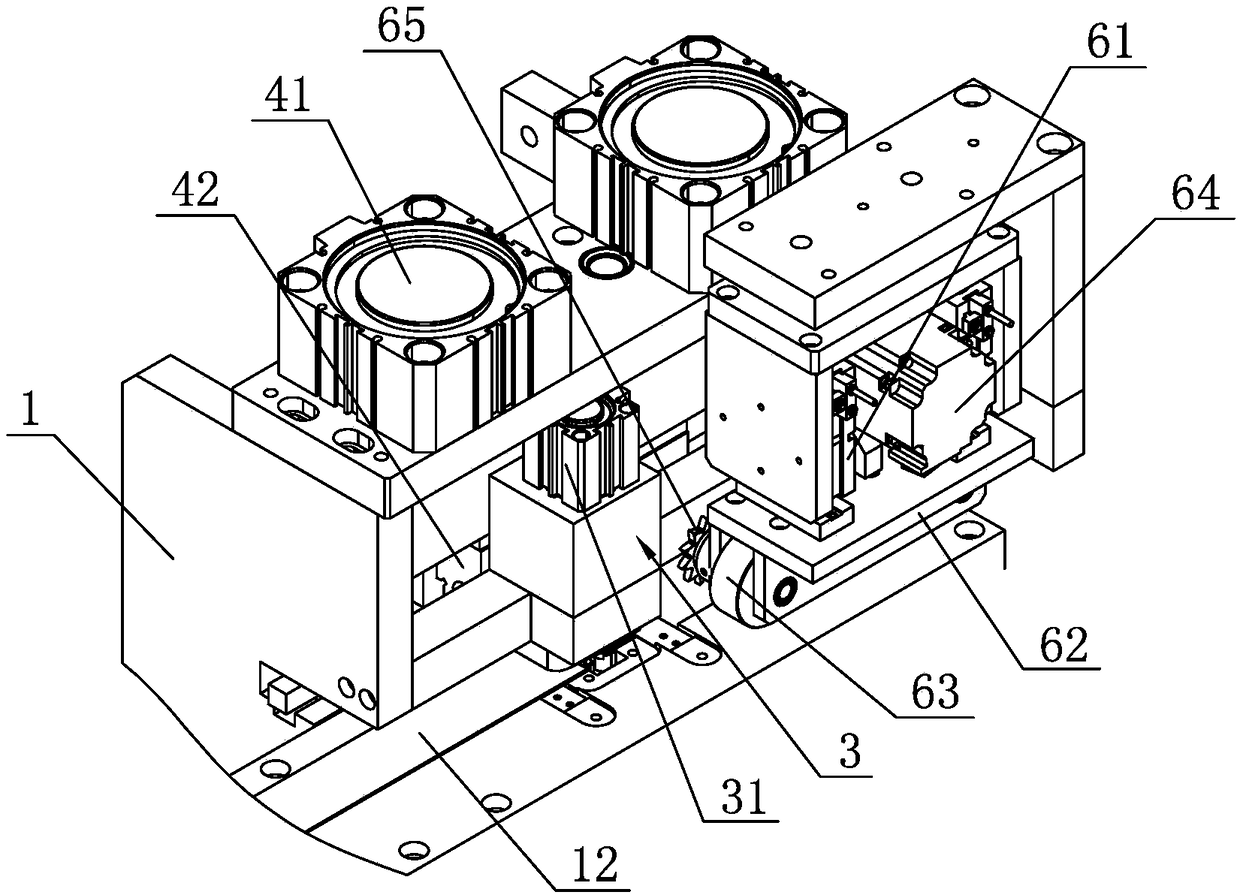

[0017] As shown in the figure, an index card automatic lamination machine includes a frame 1 and a film transfer mechanism 2, a film cutting mechanism 3, a heat press mechanism 4, an index card transfer mechanism 5 and a discharge mechanism arranged on the frame 1 6. The frame 1 is provided with a guide groove 11 for transporting the film, the film transfer mechanism 2 is located at the entrance of the guide groove 11, the guide groove 11 is fixed with a groove cover 12, and the film cutting mechanism 3 is located on the groove cover At the inner end of 12, the hot pressing mechanism 4 and the index card conveying mechanism 5 are respectively located on both sides of the guide groove 11 and facing each other, and the conveying direction of the index card is perpendicular to the conveying direction of the adhesive film;

[0018] The film transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com