Automatic film laminating production line for metal part

A technology of production line and metal parts, which is applied in the field of automatic film laminating production line for metal parts, can solve the problems of low film lamination accuracy and easy scratches of metal parts, and achieve the effect of precise film position, convenient operation and anti-scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

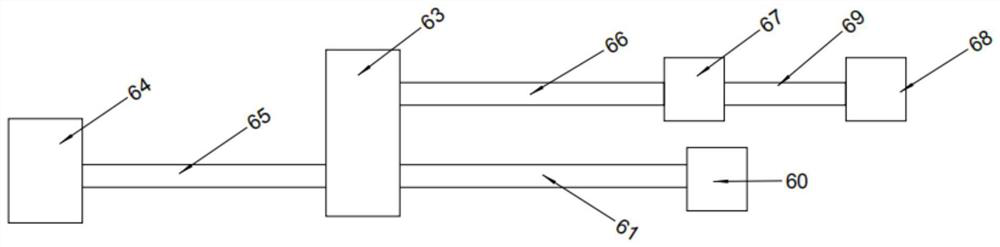

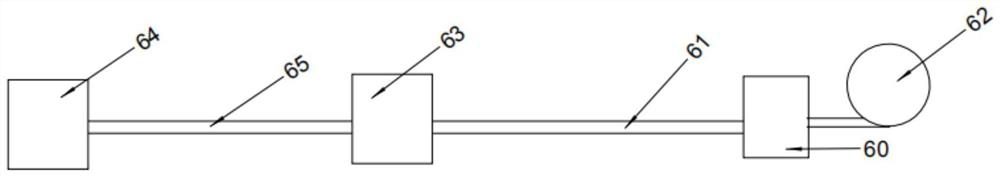

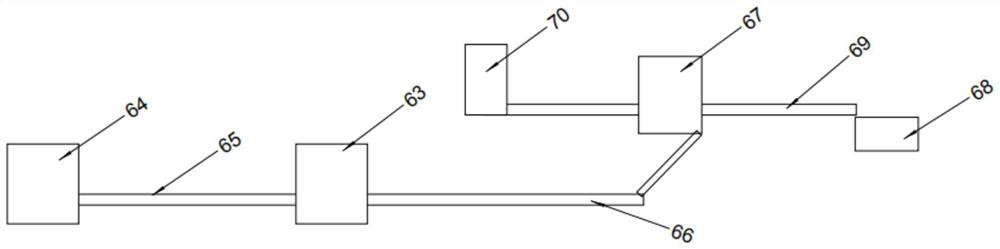

[0039] Such as Figure 1 to Figure 3 As shown, the automatic film laminating production line for metal parts includes: a die-cutting machine 60, a first conveyor belt 61, a film unwinding device 62, a laminating machine 63, a receiving device 64, a second conveyor belt 65, a third conveyor belt 66, and metal stamping Mold 67 , recovery device 68 , fourth conveyor belt 69 , storage device 70 . Described die-cutting production line comprises film sticking unwinding device 62, die-cutting machine 60 and first conveyer belt 61, and described film sticking unwinding device 62 is connected with die-cutting machine 60, and film sticking unwinding device 62 is used for placing adhesive film, will One end of adhesive film is connected with die-cutting machine 60, and die-cutting machine 60 just cuts adhesive film into predetermined size, and described die-cutting machine 60 is connected with first conveyer belt 61, and first conveyer belt 61 is used for conveying cut adhesive film .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com