Double-drum type self-plugging rivet

A blind rivet, drum-shaped technology, applied in rivets and other directions, can solve the problems of rough appearance, single use, low rivet strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

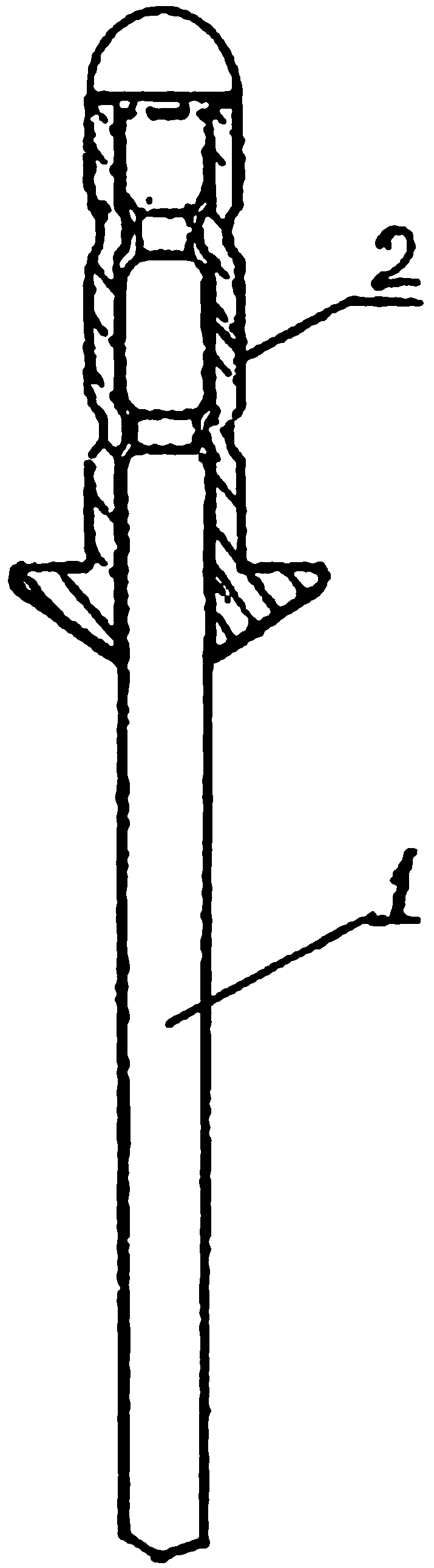

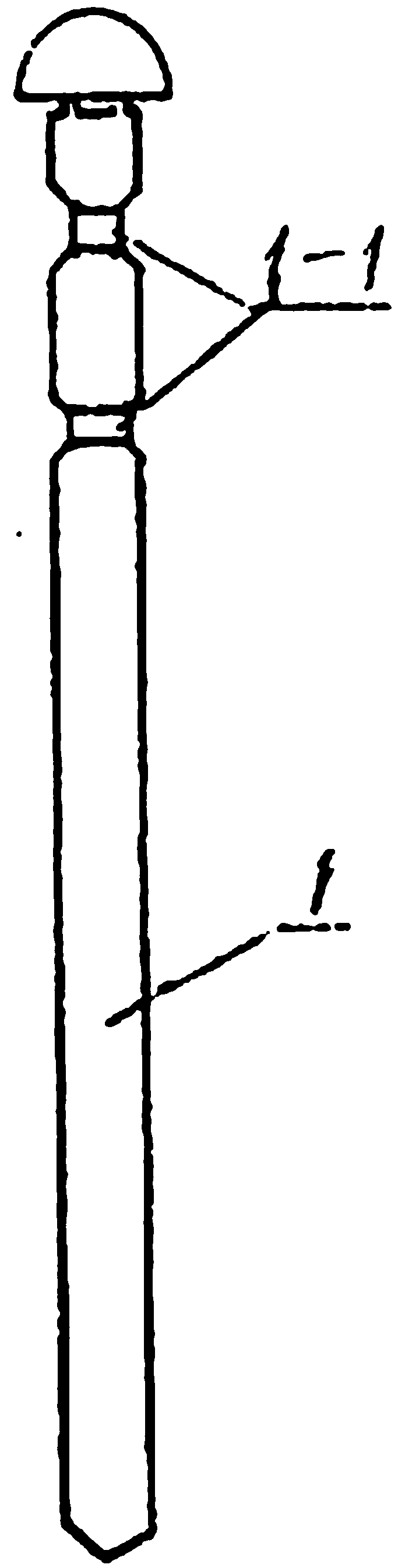

[0009] The production and processing process of the double-drum type blind rivet: firstly, a special machine is used to pre-process two grooves (1-1) on the mandrel nail (1), and there will be two grooves (1-1) ) mandrel nail (1) for cleaning and annealing treatment, and then use a self-made special machine and mold to place the The metal aluminum material is squeezed inward at the two grooves (1-1) and pressed at the same time to form a metal double drum (2) and a double drum type blind rivet. It has high smoothness, clean and beautiful appearance, novel shape and wide range of applications. Due to the use of self-made special machines for production, the production efficiency is improved. It is suitable for mass production and meets the needs of the market.

[0010] According to above-mentioned making promptly constitute the present invention---a kind of double-drum type blind rivet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com