Device and method for in-situ testing of earth pressure

A technology of in-situ testing and testing methods, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as distortion of measurement results, and achieve the effect of clear mechanical concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

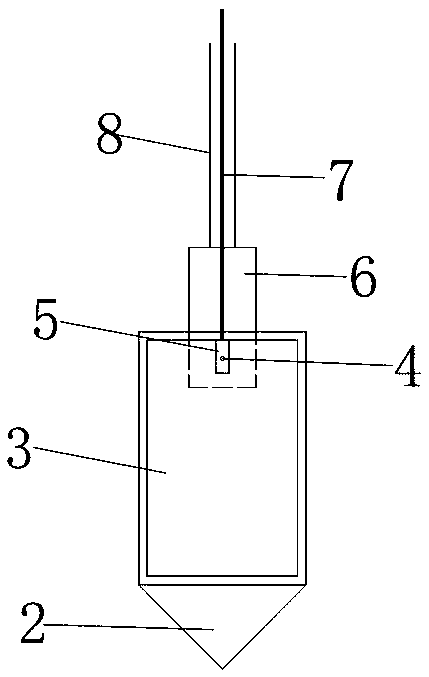

[0031] Embodiment 1: as figure 1 , 2 As shown, the present embodiment specifically relates to an in-situ earth pressure testing device, which includes a back panel 2; groove; the front of the back panel 2 is also provided with an elastic contact panel 1, and the elastic contact panel 1 and the groove are enclosed to form a sealed hydraulic cavity 3; the back panel 2 is provided with a hydraulic gauge 5, and the hydraulic gauge 5 passes through the pressure transmission tube 4 It communicates with the hydraulic cavity 3; the hydraulic cavity 3 and the pressure transmission pipe 4 are filled with liquid; the hydraulic gauge 5 is used to measure the liquid pressure inside the hydraulic cavity 3.

[0032] like figure 1 , 2 As shown, the elastic contact panel 1 is a metal plate with a relatively thin thickness; the elastic contact panel 1 can produce slight deformation under the action of earth pressure, resulting in an increase in the pressure inside the hydraulic cavity 3; Th...

Embodiment 2

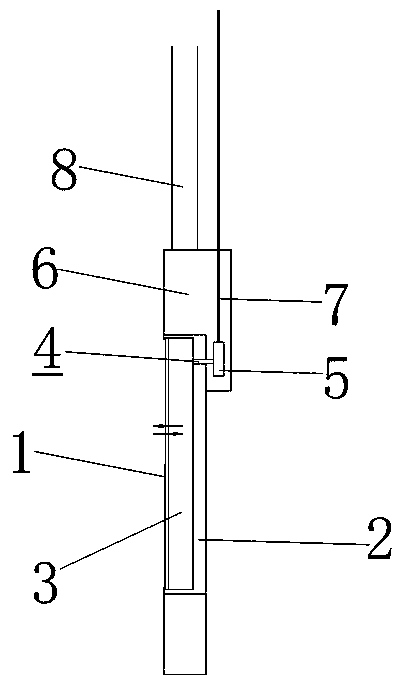

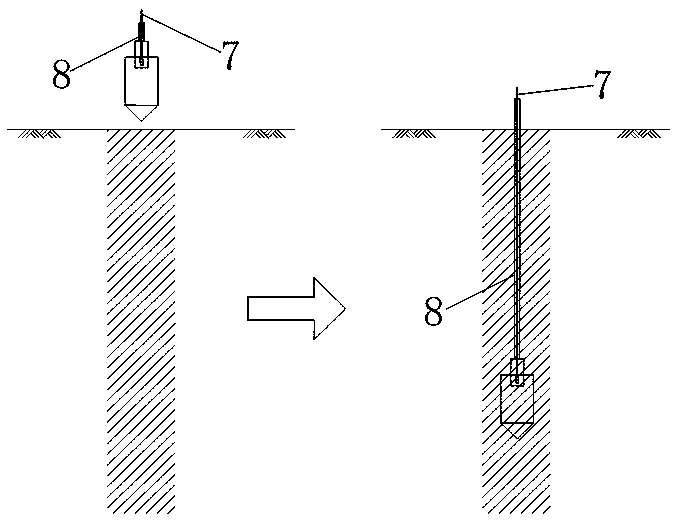

[0046] Embodiment 2: as Figure 5 , 6 As shown, the main difference between this embodiment and Embodiment 1 lies in the shape of the bottom of the back panel 2 and the installation method of the hydraulic gauge 5; in this embodiment, the bottom of the back panel 2 is wedge-shaped; in this embodiment, the hydraulic cavity 3 The top of the top is provided with a pressure transmission tube 4; the hydraulic gauge is installed on the top of the back panel 2, and is connected with the hydraulic cavity through the pressure transmission tube 4; the signal line of the hydraulic gauge 5 is arranged on the outside of the rigid rod 8; in addition, the present embodiment The middle rigid rod 8 is directly connected to the top of the back panel 2, and the top of the back panel 2 has no connection end.

Embodiment 3

[0047] Embodiment 3: as Figure 7 , 8 As shown, the main difference between this embodiment and Embodiment 1 lies in the installation method of the hydraulic gauge 5; in this embodiment, the hydraulic gauge 5 is embedded on the inner surface of the hydraulic cavity 3, and the hydraulic gauge 5 is directly connected to the hydraulic cavity 3; In addition, in this embodiment, the bottom of the back panel 2 is an arc-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com