Automatic visual inspection system for motor commutator

A motor commutator and visual inspection technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as defective products and dust adhesion, and achieve the effect of ensuring quality, reducing the probability of damage and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

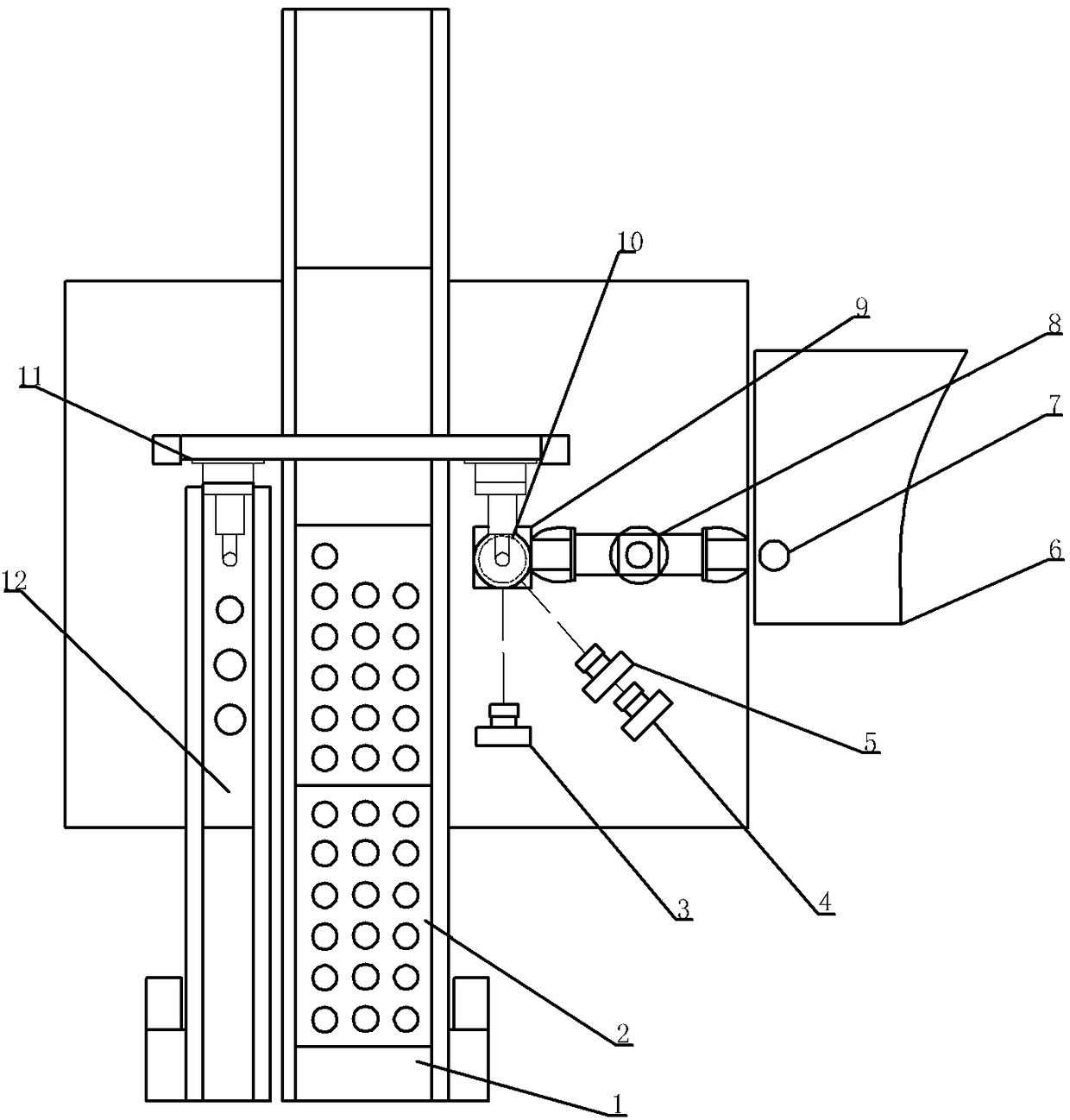

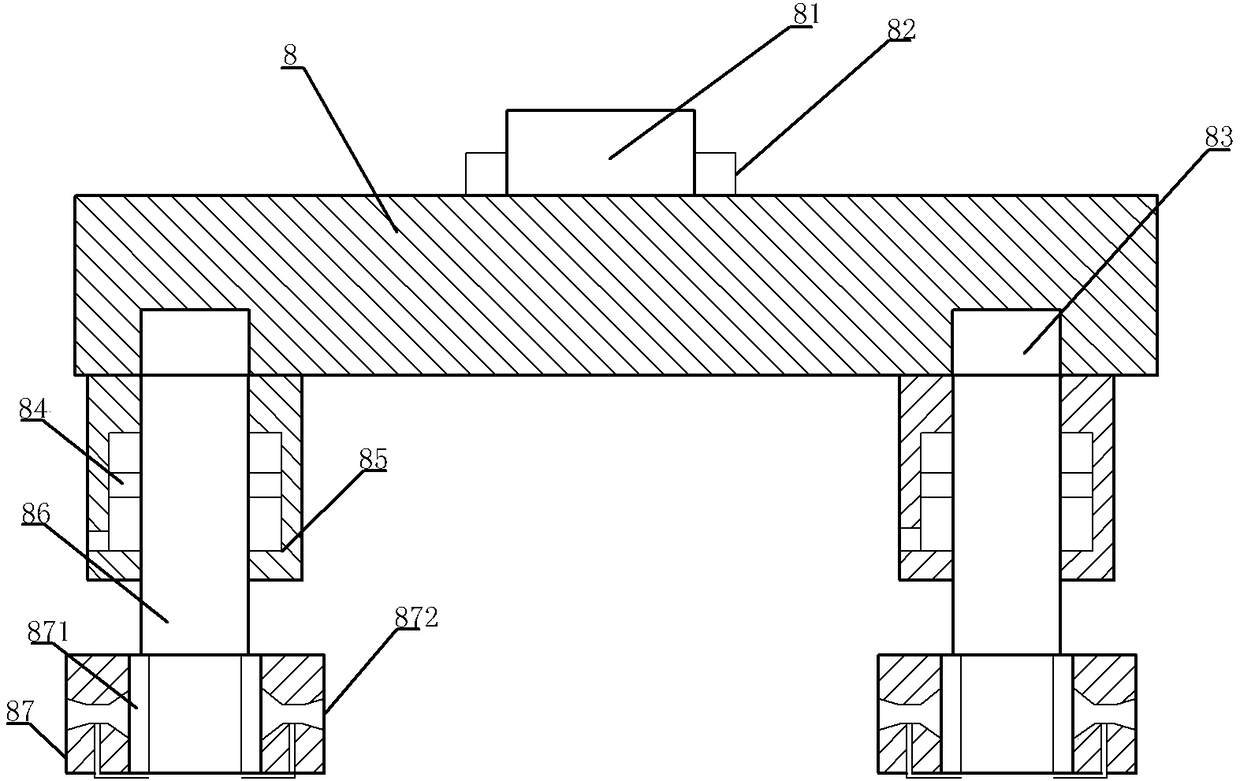

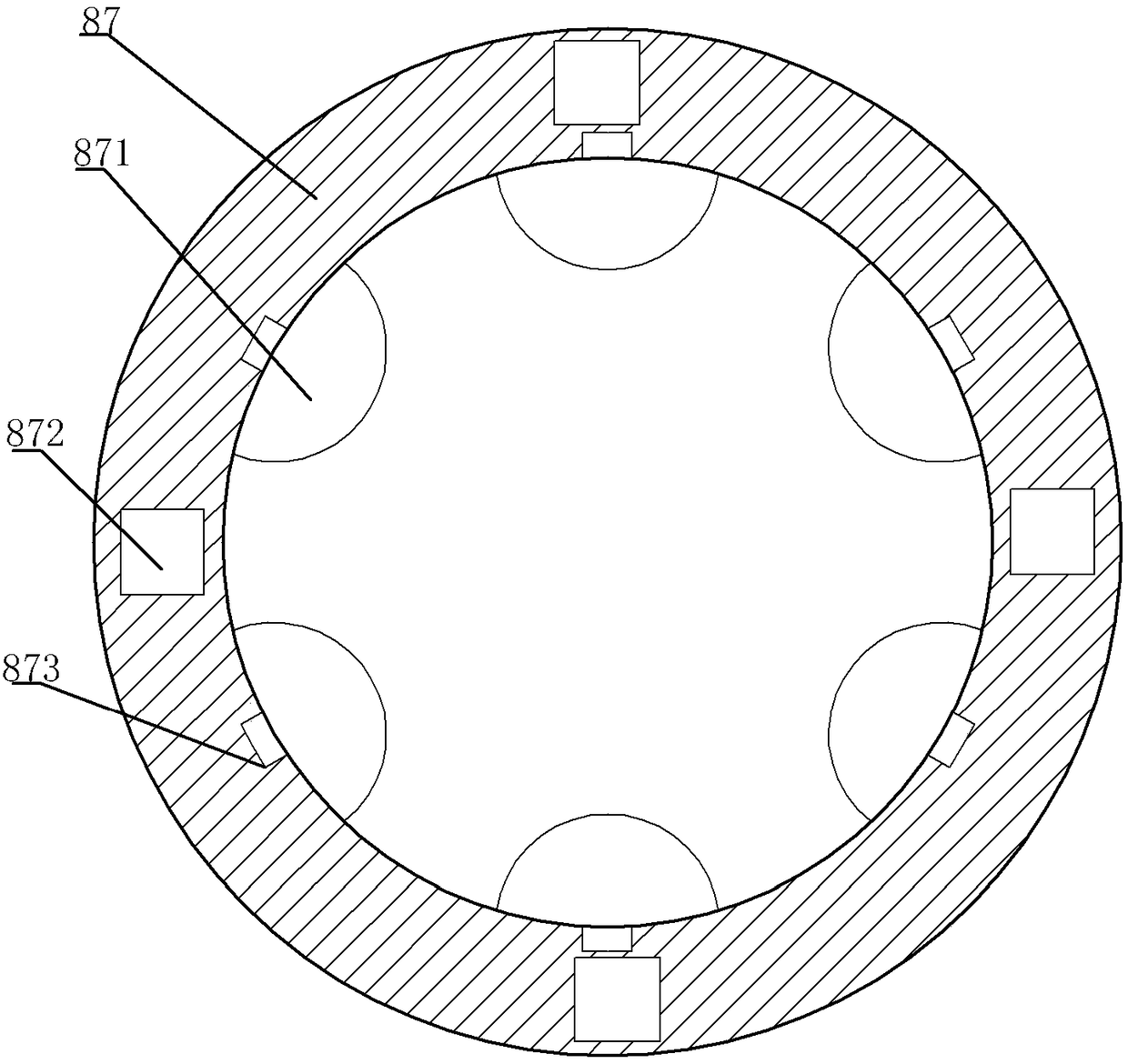

[0023] as attached figure 1 , attached figure 2 And attached image 3As shown, an automatic visual inspection system for motor commutators, a frame, a two-axis truss robot 11, a bottom image acquisition device 9, a top image acquisition device 10, a positioning rotary device, a cylindrical surface image acquisition device 4, and a conical surface image acquisition device Device 5, control device 1, good product transport device 2, defective product platform 12 and transport device. The bottom image acquisition device 9 is installed under the workbench of the frame and is located at one end of the two-axis truss robot 11, the positioning and turning device is located at one end of the two-axis truss robot 11, and the top image acquisition device 10 is arranged above the positioning and turning device. The field of view of the image acquisition device 4 is aligned with the cylindrical surface of the commutator 7, and the field of view of the conical surface image acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com